Device for conveying discharged mud cakes of plate-and-frame filter press

A technology of plate and frame filter press and conveying device, which is applied in the field of conveying device for mud cake unloaded by plate and frame filter press, which can solve problems such as belt deviation, inappropriateness, and high labor intensity of inspection workers, and achieve the degree of automation High quality, low quality requirements, and the effect of reducing labor intensity and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

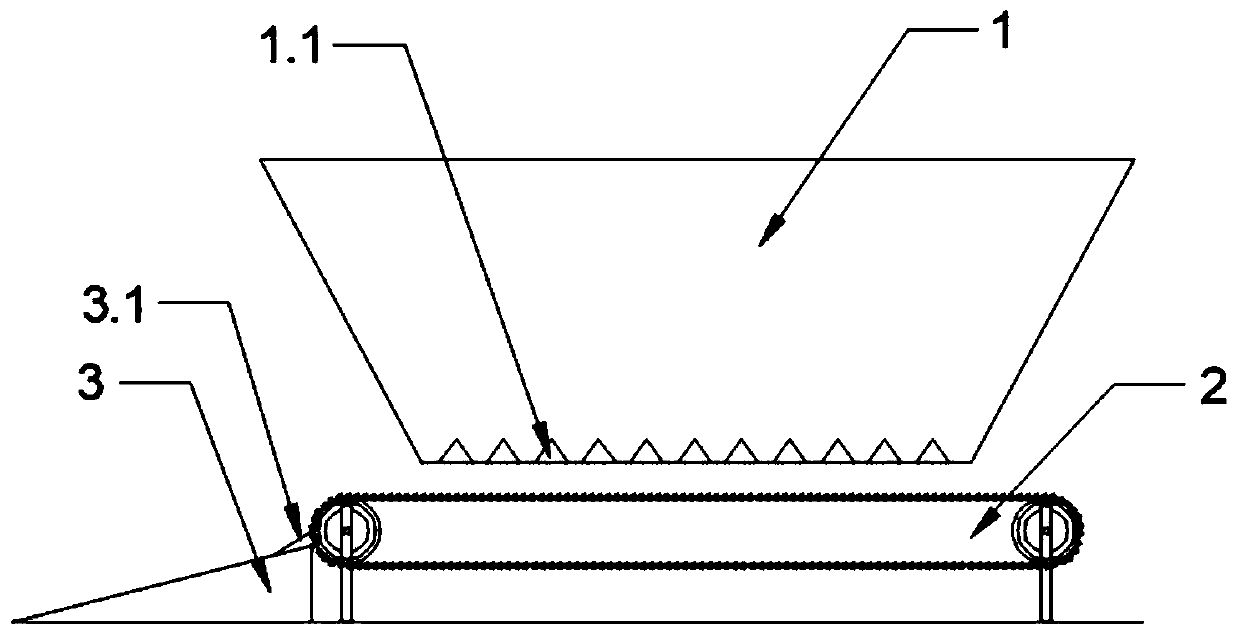

[0035] Such as Figure 1-2 As shown in the figure, a conveying device for feeding mud cake of a plate and frame filter press, including a mud hopper 1, a conveyor 2 located directly below the mud hopper 1, and a grille is provided at the lower part of the mud hopper 1 1.1; the grid 1.1 can be a toothed grid, and the toothed grid has a toothed cutting edge for accelerating the division of the mud cake.

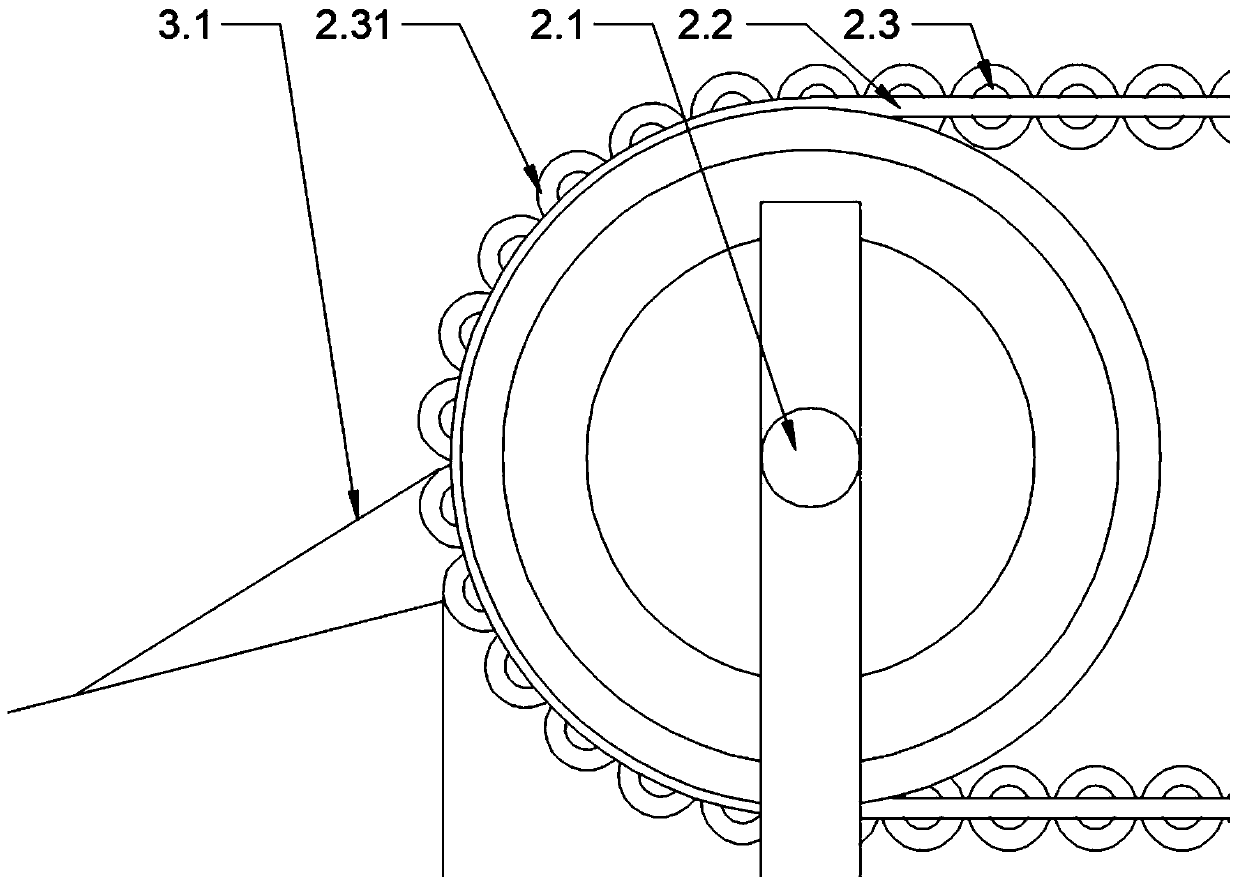

[0036] The conveyor 2 includes two main rotating shafts 2.1 and a first rotating motor electrically connected to the main rotating shaft 2.1 on either side thereof, the two main rotating shafts 2.1 are arranged in parallel and spaced apart, and both ends of the main rotating shaft 2.1 are fixed A sprocket is connected, and the sprockets on the same side of the two main shafts 2.1 are located on the same plane and are meshed and connected by a chain 2.2. A plurality of central shafts 2.3 parallel to the main shaft are arranged between the two chains 2.2. The two ends of the cen...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that the conveying device further includes a processor, the second rotating motor communicates with the cylindrical roller 2.31 through the processor, and the pressure sensor communicates with the third rotating motor through the processor. Motor communication connection; when the value measured by the pressure sensor exceeds the predetermined value, the processor receives the signal of the pressure sensor, and sends control signals to the second rotating motor and the third rotating motor in sequence to realize automatic control.

Embodiment 3

[0041] A method for conveying mud cake for plate and frame filter press, comprising the following steps:

[0042] S1, the plate and frame filter press discharges the mud cake into the mud hopper 1, and after being destroyed by the lower grille 1.1 of the mud hopper 1, several mud clods with smaller particle sizes fall to the cylindrical drum 2.31 of the conveyor 2 below. upper surface;

[0043] S2, the cylindrical drum 2.31 transports the mud block to the mud outlet gentle slope 3, and the mud block falls from the cylindrical drum 2.31 due to gravity;

[0044] S3, when the cylindrical drum 2.31 moves to directly above the mud discharge gentle slope 3, it is determined whether there is mud left on the current cylindrical drum 2.31;

[0045] S4, if mud material remains on the current cylindrical drum 2.31, then clean the surface of the cylindrical drum 2.31; otherwise, continue to transport the mud.

[0046] Wherein, the specific determination steps in the step S3 include:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com