Intermediate slab connecting equipment and system

A technology for connecting equipment and blades, used in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of slow connection speed, low connection strength of intermediate blanks, and large equipment, and achieve fast connection speed and high connection strength. , the effect of simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

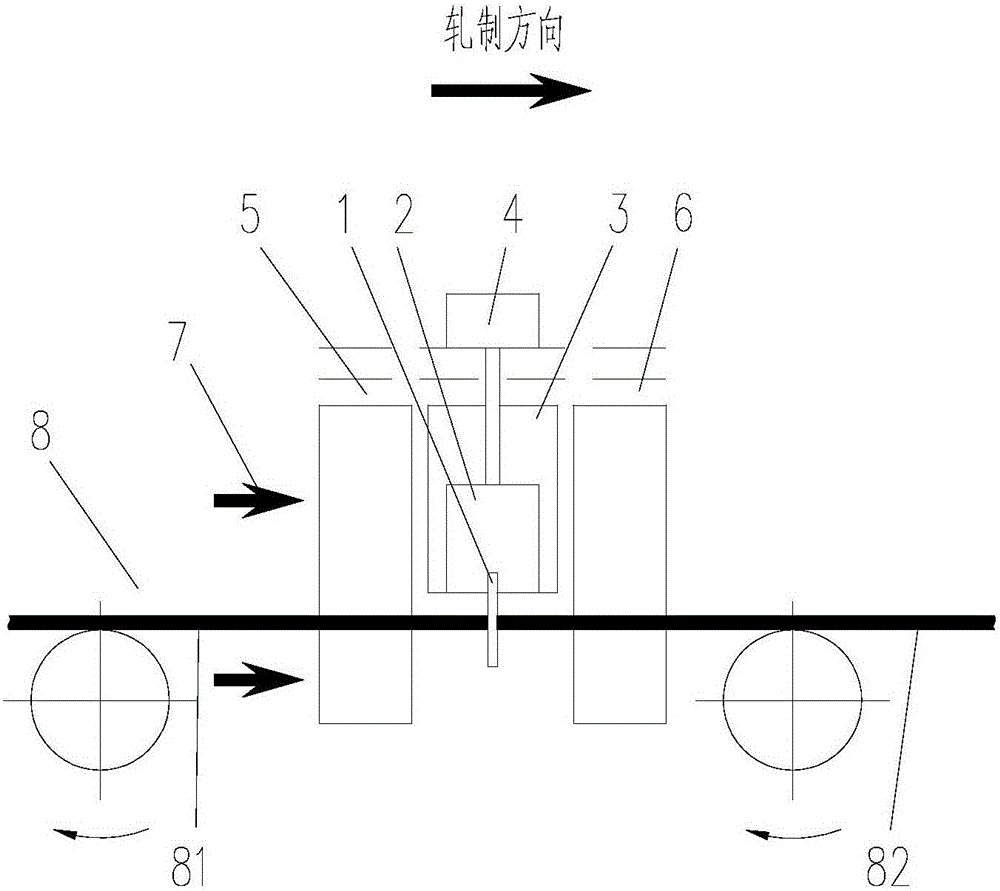

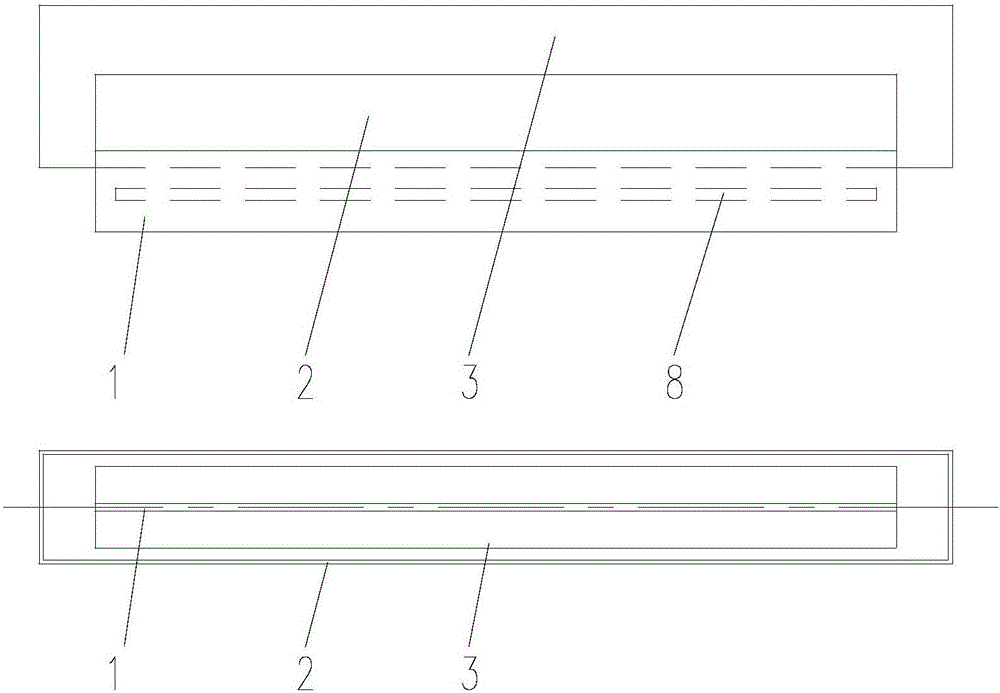

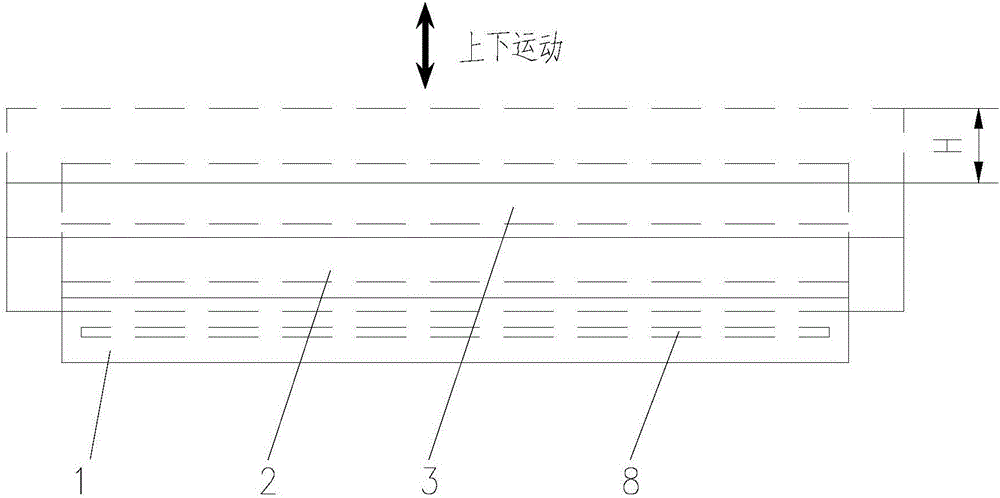

[0057] Such as figure 1 and figure 2 As shown, the present invention provides an intermediate blank connecting device 500 for connecting the front intermediate blank 82 and the rear intermediate blank 81, mainly including a friction blade 1, a friction blade vibrating tool holder 2, and a friction blade pressing tool holder 3 , Friction blade vibrating device 4, inlet clamping device 5, outlet clamping device 6 and upsetting device 7.

[0058] Wherein, the entrance clamping device 5 is used to clamp the rear block intermediate blank 81, the outlet clamping device 6 is used to clamp the front block intermediate blank 82, the friction blade 1 is installed on the friction blade vibrating tool rest 2, and the friction blade vibrating tool rest 2 Installed in the friction blade pressing tool holder 3;

[0059] The friction blade 1 is located between the inlet clamping device 5 and the outlet clamping device 6, and the friction blade 1 is vibrated by the friction blade vibrating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com