Car arrester module capable of achieving modularization assembling and matrix car arrester

A vehicle arrester and matrix technology, applied in the field of matrix vehicle arresters, can solve the problems of large volume and weight, large volume, heavy weight, etc., and achieve the effects of wide application range, high structural strength and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

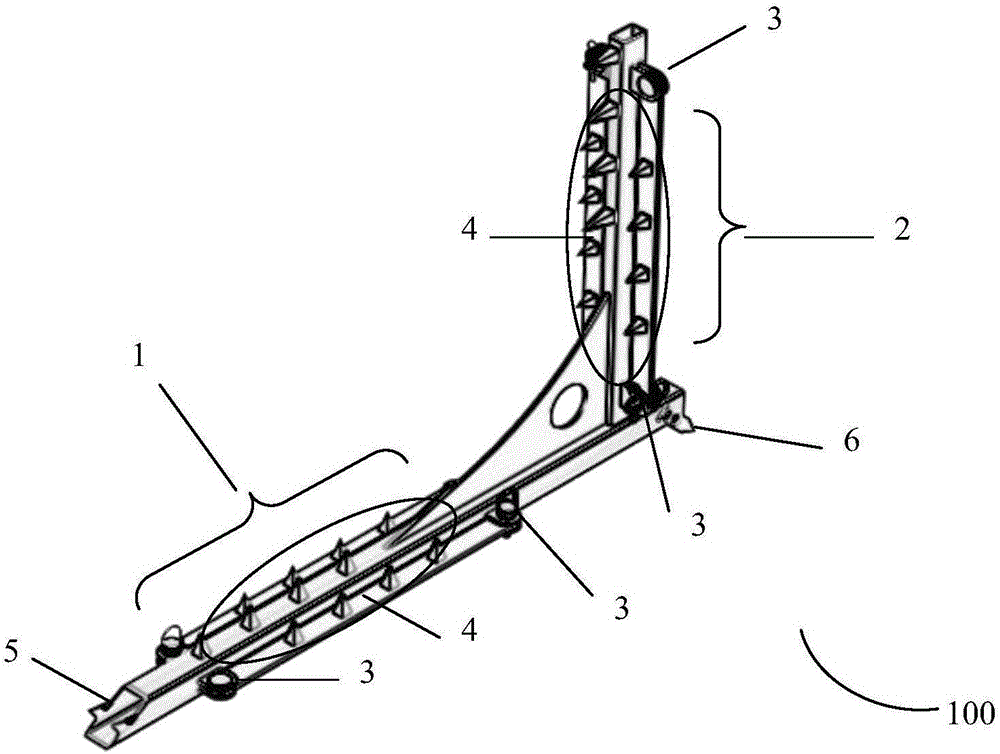

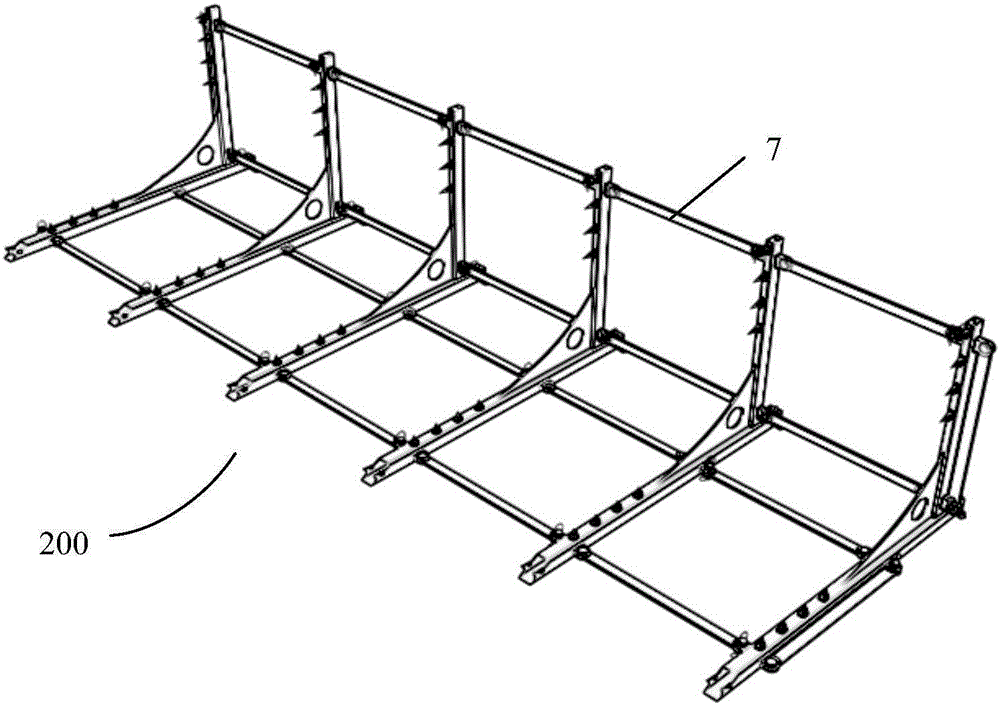

[0043] figure 1 A schematic structural diagram showing the vehicle arrester module 100 according to the first embodiment of the present invention; figure 2 is multiple figure 1 A schematic diagram of a vehicle arrester array 200 formed by matrix splicing of the vehicle arrester modules 100 shown.

[0044] The vehicle arrester module shown in the first embodiment proposes a light-duty vehicle arrester solution. The vehicle arrester module 100 has an L-shaped frame structure and is composed of a beam 1 and a vertical beam 2 . The horizontal and vertical beams are fixed and connected at a 90-degree angle through a triangular connection web, which cannot be folded or split. For example, the frame body of the vehicle arrester module 100 can be cut and welded by a 4mm square steel pipe and a 5mm thick connecting web. Of course, the embodiments of the present invention are not limited to the boards with the above-mentioned dimensions, and the above-mentioned dimension descript...

no. 2 example

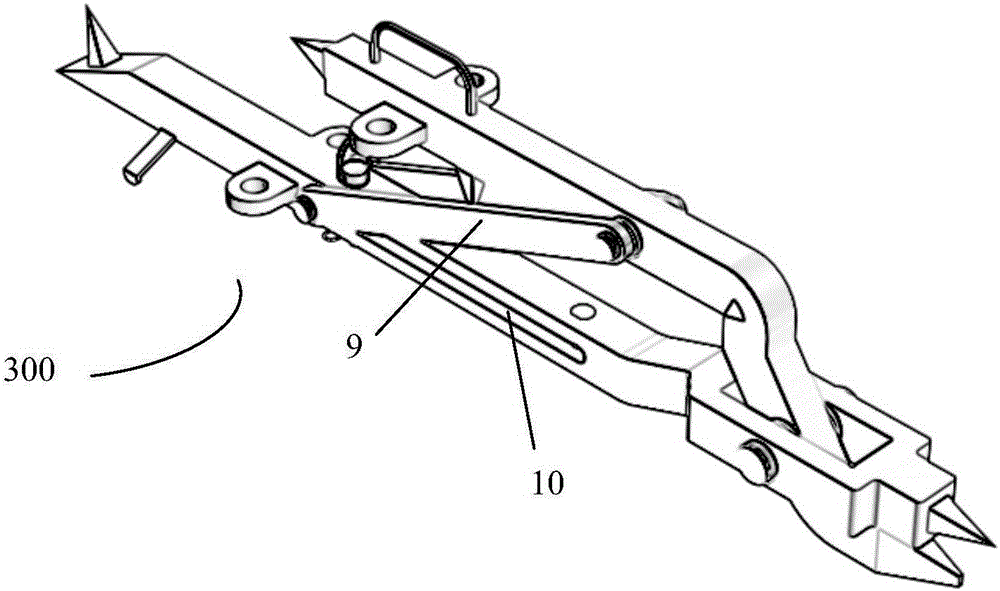

[0053] image 3 and Figure 4 Respectively show the schematic structural diagrams of the vehicle arrester module 300 in the folded configuration and the unfolded configuration according to the second embodiment of the present invention; Figure 5 Shown is a vehicle arrester array 500 formed by splicing a plurality of vehicle arrester modules 300 in a matrix.

[0054] The vehicle arrester module shown in the second embodiment is also a light-duty vehicle arrester solution. The vehicle arrester module 300 has an L-shaped frame structure and is composed of a beam 1 and a vertical beam 2 . Different from the first embodiment, the cross beam 1 and the vertical beam 2 of the vehicle arrester 300 can be folded through the sliding connecting plate 9 . image 3 Schematic showing the folded state. Generally speaking, the frame body of the vehicle arrester module 300 is composed of three parts, the beam 1 and the vertical beam 2 are connected by a pin shaft, and the sliding connectin...

no. 3 example

[0059] Figure 6 and Figure 7 Respectively show the schematic structural diagrams of the vehicle arrester module 600 in the folded configuration and the unfolded configuration according to the third embodiment of the present invention; Figure 8 Shown is a vehicle arrester array 800 formed by splicing a plurality of vehicle arrester modules 600 in a matrix.

[0060] The vehicle arrester module shown in the third embodiment is a medium-sized vehicle arrester solution. The vehicle arrester module 600 has an L-shaped switch structure, which is composed of a beam 1 and a vertical beam 2, and the beam 1 and the vertical beam 2 are connected by bolts 5 to realize collapsibility. exist Figure 6 In the folded state shown, the vertical beam 2 is completely accommodated in the space of the cross beam 1, thereby reducing the volume of the module and making it easy to carry. The tail end of the vertical beam 2 is provided with a stand body vertical baffle plate 8, so that in the unf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com