A preparation method of polyester amide composite nanofiltration membrane with strong chlorine resistance and anti-pollution

A composite nanofiltration membrane and polyester amide technology, applied in the field of membrane separation, can solve the problems of easy pollution and poor chlorine resistance of commercial nanofiltration membranes, and achieve strong anti-pollution ability, strong hydrophilicity and good chlorine resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment 1: This embodiment provides a method for preparing a polyester amide composite nanofiltration membrane with strong chlorine resistance and pollution resistance. The specific steps are as follows:

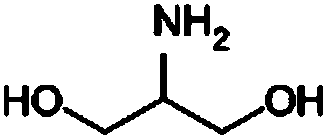

[0019] 1. Prepare the aqueous solution: add 2% (w / v) serinol to pure water (the structural formula is as figure 1 As shown), at the same time add 0.2% (w / v) 4-dimethylaminopyridine as a phase transfer and acylation catalyst, stir and dissolve thoroughly, and adjust the pH of the solution to 11.5 with triethylamine;

[0020] 2. Prepare the organic phase solution: use n-hexane as the organic solvent and add 0.1% (w / v) polyacid chloride to the organic solvent;

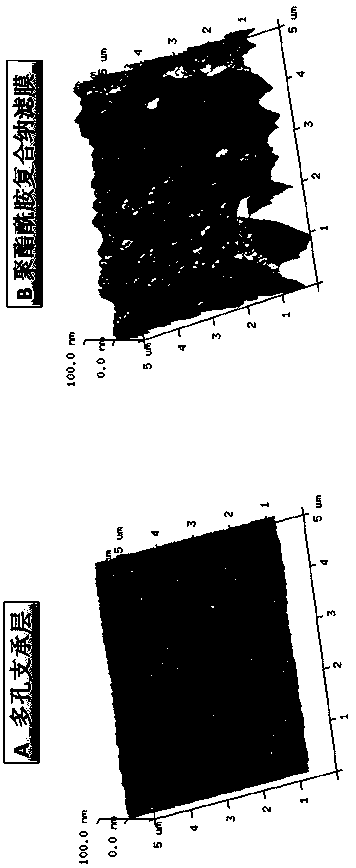

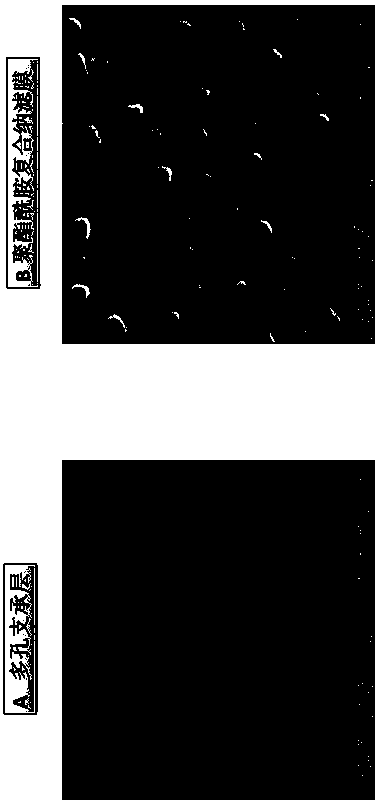

[0021] 3. With the polyethersulfone porous ultrafiltration membrane as the support layer, first pour the aqueous solution onto the surface of the support layer and soak for 2 minutes, then pour the aqueous solution and remove the excess water on the membrane surface, and then pour the organic solution onto th...

specific Embodiment approach 2

[0027] Embodiment 2: This embodiment provides a method for preparing a polyester amide composite nanofiltration membrane with strong chlorine resistance and pollution resistance. The specific steps are as follows:

[0028] 1. To prepare the aqueous solution: add 1% (w / v) serinol to pure water (its structural formula is as figure 1 As shown), at the same time add 0.2% (w / v) 4-dimethylaminopyridine as a phase transfer and acylation catalyst, stir and dissolve thoroughly, and adjust the pH of the solution to 11.5 with triethylamine;

[0029] 2. Prepare the organic phase solution: use n-octane as the organic solvent and add 0.05% (w / v) polyacid chloride to the organic solvent;

[0030] 3. With polysulfone porous ultrafiltration membrane as the support layer, first pour the aqueous solution onto the surface of the support layer and soak for 2 minutes, then pour the aqueous solution and remove excess water on the membrane surface, and then pour the organic phase solution onto the membrane s...

specific Embodiment approach 3

[0033] Specific embodiment 3: This embodiment provides a method for preparing a polyester amide composite nanofiltration membrane with strong chlorine resistance and pollution resistance. The specific steps are as follows:

[0034] 1. Prepare the aqueous solution: add 0.5% (w / v) serinol to pure water (the structural formula is as figure 1 As shown), at the same time add 0.05% (w / v) 4-dimethylaminopyridine as a phase transfer and acylation catalyst, stir and dissolve thoroughly, and adjust the pH of the solution to 11.5 with triethylamine;

[0035] 2. Prepare the organic phase solution: use toluene and cyclohexane as organic solvents, with a volume ratio of 1:1, and add 0.05% (w / v) polyacid chloride to the organic solvent;

[0036] 3. Using polypropylene porous ultrafiltration membrane as the support layer, first pour the aqueous solution onto the surface of the support layer and soak for 4 minutes, then pour the aqueous solution and remove excess water on the membrane surface, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com