Vibration-reducing blasting construction method of air spring

A construction method and air spring technology, applied in blasting, excavation, infrastructure engineering, etc., can solve the problems of too much impact on building safety, failure to achieve blasting effect, and decline in rock destructive ability, so as to improve blasting efficiency and improve blasting performance. Effect, effect of increasing the range of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036] The air spring damping blasting construction method of the present invention is suitable for rock-soil blasting in dense urban areas, various rock-soil blasting with strict requirements for protection facilities around blasting areas, local cutting blasting of large concrete blocks, and large-scale rock-soil blasting occasions.

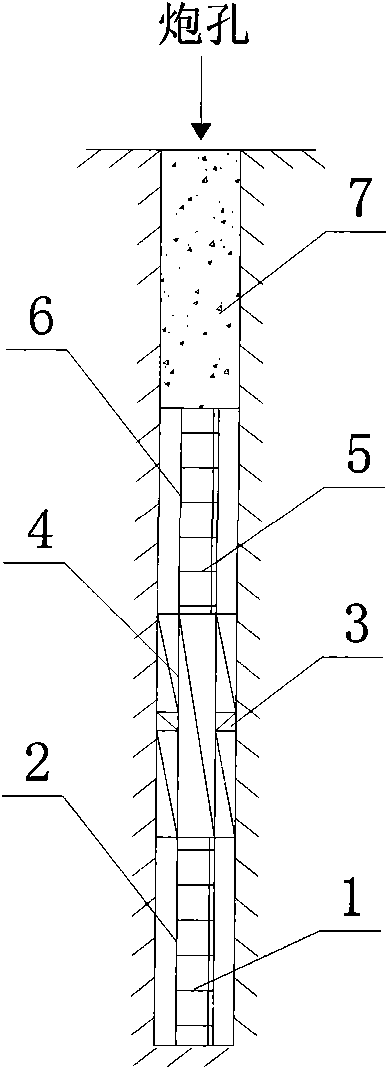

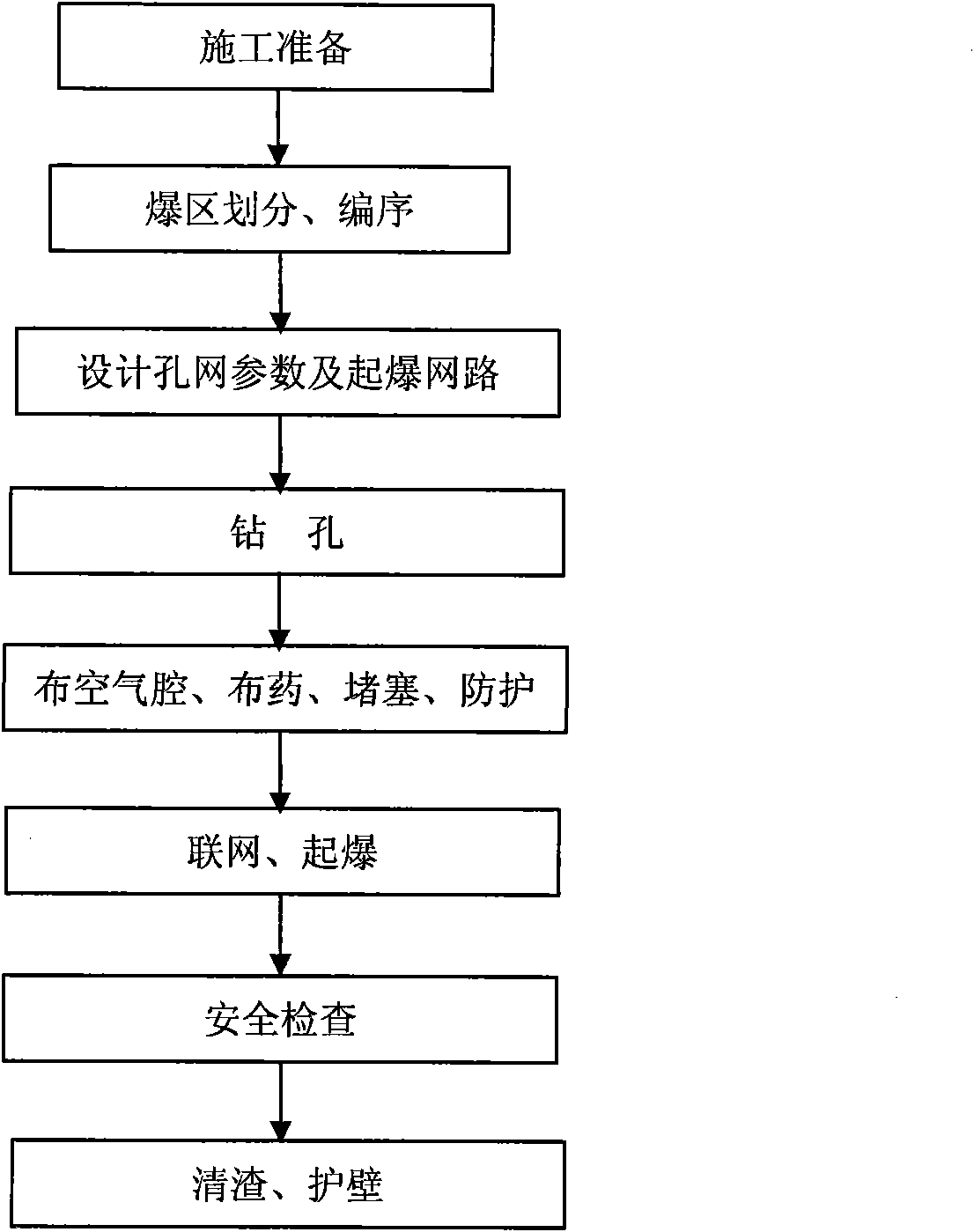

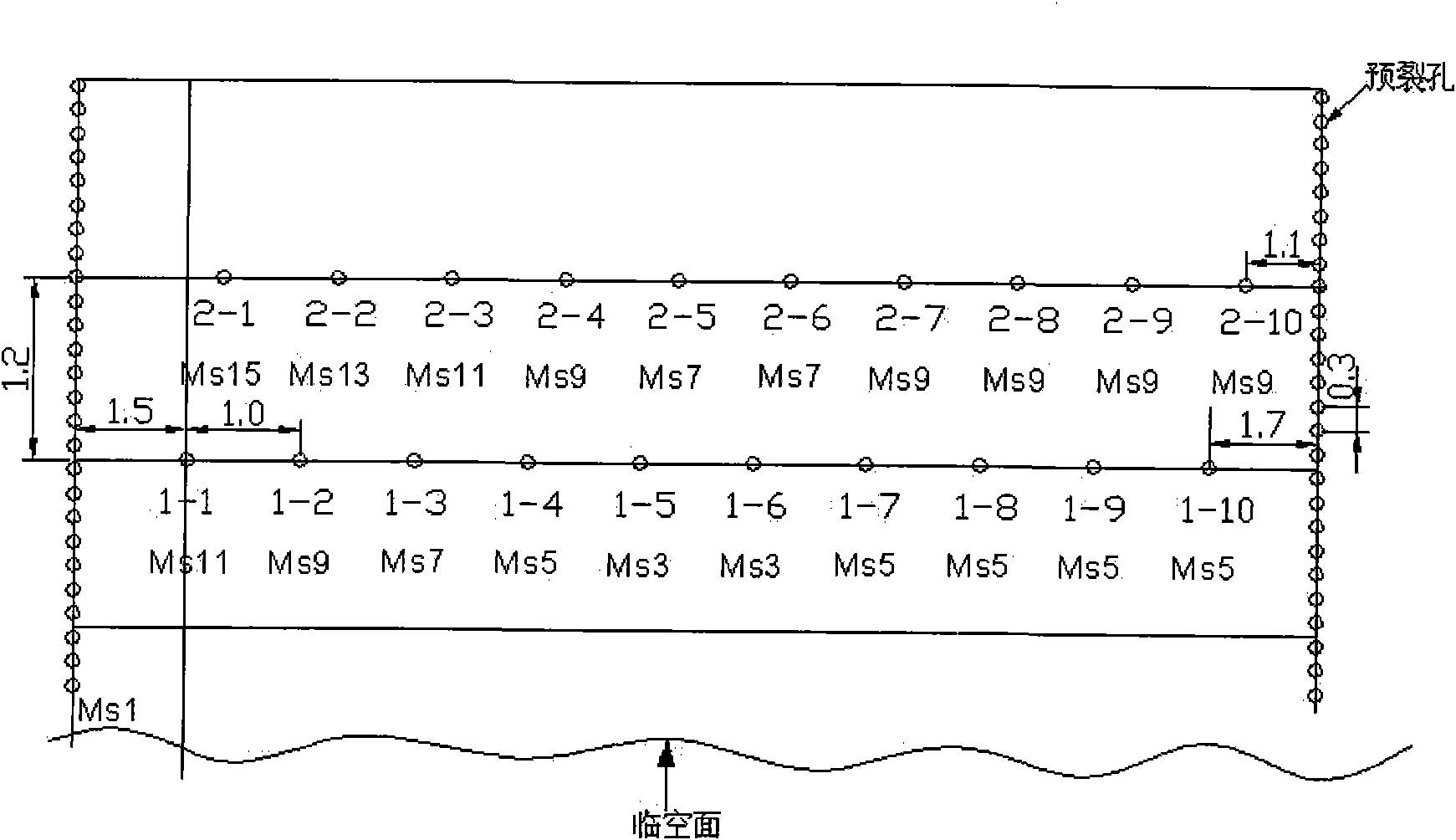

[0037] The construction method of the present invention is to design the hole network parameters and the detonation network in the divided blasting area, and to drill holes and fill explosives at the determined blast hole points; figure 1 As shown, its innovative point is that when charging the gun hole, the following steps are followed:

[0038] 1) After checking that the hole layout meets the design requirements, reserve an air cavity 1 at the bottom of the hole of 300mm to 500mm. The air cavity 1 at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com