Clean low energy consumption synthesis ammonia production method

A production method and technology for synthesizing ammonia, applied in chemical instruments and methods, preparation of urea derivatives, preparation/separation of ammonia, etc., can solve the problems of high coal consumption and energy consumption of raw materials, backward gas production process, pollution, etc., and achieve reduction of raw materials Coal consumption and the effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

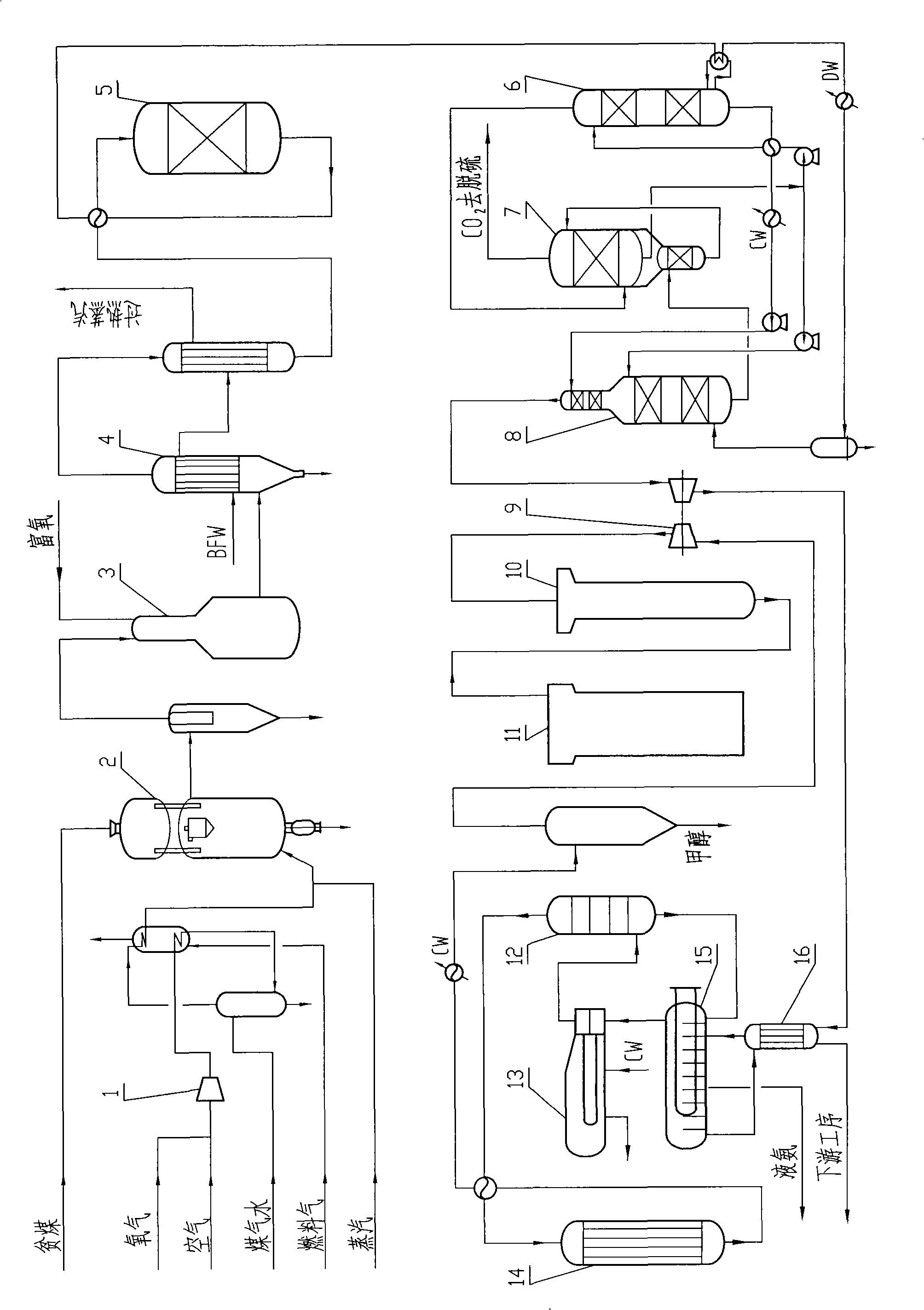

Method used

Image

Examples

Embodiment Construction

[0032] There were 55 medium-sized nitrogen fertilizer enterprises in my country in 1990, with a production capacity of about 5.6 million tons of synthetic ammonia. The output of synthetic ammonia accounted for 22.8% of the national output of synthetic ammonia, 30% of the national output of urea, and 90% of the national output of ammonium nitrate. The development of our country's national economy plays an important backbone role.

[0033] Among the 55 medium-sized nitrogen fertilizer enterprises, there are about 35 whose raw materials are mainly anthracite lump coal, most of which were built in the 1960s and 1970s, and the gas production process is relatively backward. For more than ten years, the raw material is still mainly anthracite lump coal, and the gas production process still uses the intermittent air atmospheric pressure gasification method. The raw material coal consumption is high, the energy consumption is large, and the pollution is serious. With the continuous pric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com