Coal seam reticulated gas extraction drilling construction method of water jet drilling machine

A technology of gas drainage and construction method, which is applied in earth-moving drilling, drilling with liquid/gas jet, directional drilling, etc., can solve the problems such as the inability to realize the construction method of coal seam mesh gas drainage and the lack of water jet drilling rigs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

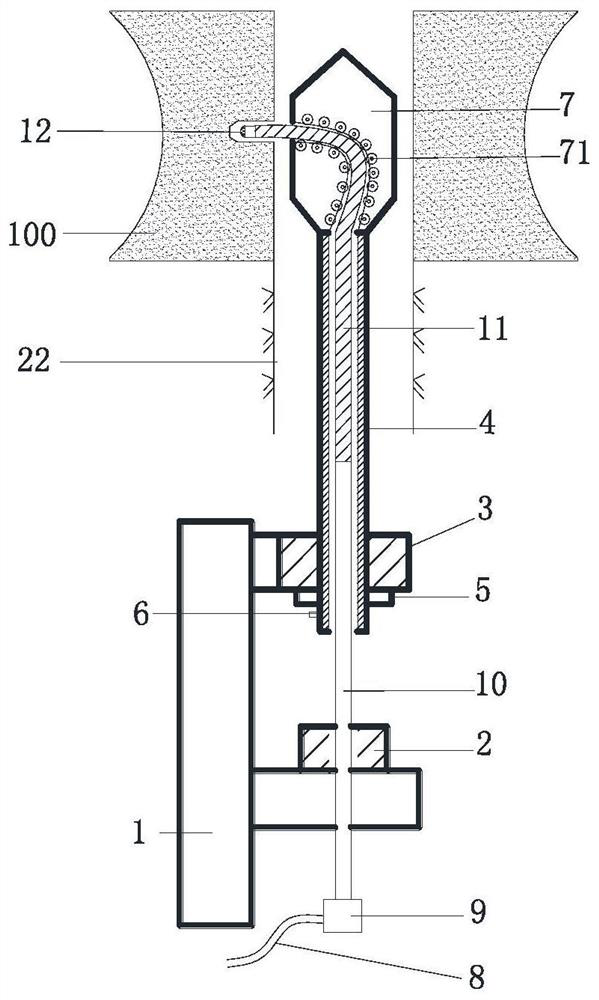

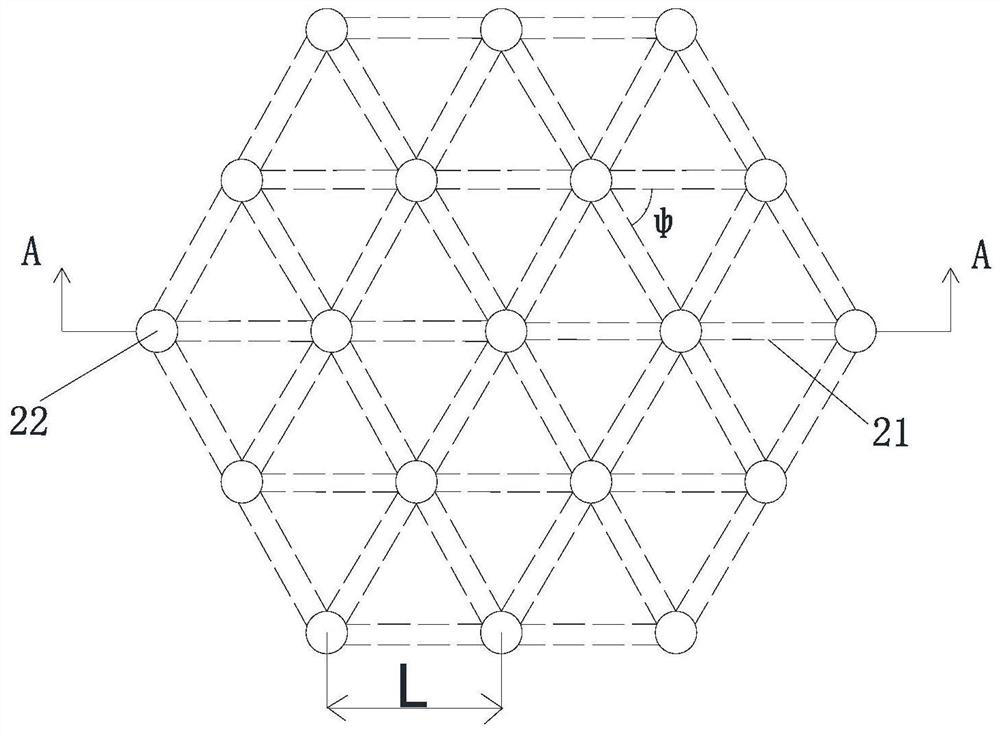

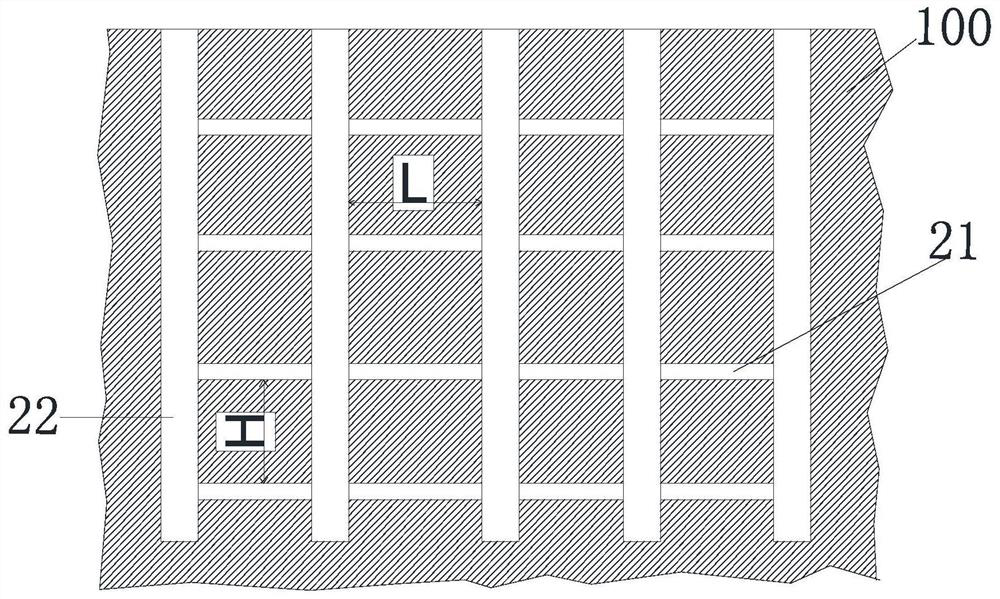

[0026] see figure 1 , figure 2 , image 3 , Figure 5 , Figure 6 A coal seam mesh gas drainage drilling method for a water jet drilling rig, comprising drilling a number of (diameter greater than 150 mm) water jet construction drilling 22 in a coal seam 100, characterized in that: ① Utilizing a water jet drilling rig, The outer drill pipe 4 with the flexible drill pipe rotator 7 is inserted into the bottom of the water jet construction drill hole 22 in the coal seam 100, and the outer drill pipe 4 is fixed on the main body 1 of the drilling rig with the outer drill pipe holder 3 of the drilling rig. The drill pipe holder 2 fixes the inner drill pipe 10 on the main body 1 of the drilling rig, so that the water jet nozzle 12 enters the flexible drill pipe rotator 7, and ② uses the 360° orientation mark fixed on the outer drill pipe holder 3 of the drilling rig Plate 5, push and pull the handle 404 to adjust the angle, make the water drop level 409 in a horizontal state, ti...

no. 2 example

[0032] see figure 1 , Figure 4 , Figure 5 , Figure 6 A coal seam mesh gas drainage drilling method for a water jet drilling rig, comprising drilling a number of (diameter greater than 150 mm) water jet construction drilling 22 in a coal seam 100, characterized in that: ① Utilizing a water jet drilling rig, The outer drill pipe 4 with the flexible drill pipe rotator 7 is inserted into the bottom of the water jet construction drill hole 22 in the coal seam 100, and the outer drill pipe 4 is fixed on the main body 1 of the drilling rig with the outer drill pipe holder 3 of the drilling rig. The drill pipe holder 2 fixes the inner drill pipe 10 on the main body 1 of the drilling rig, so that the water jet nozzle 12 enters the flexible drill pipe rotator 7, and ② uses the 360° orientation mark fixed on the outer drill pipe holder 3 of the drilling rig Plate 5, push and pull the handle 404 to adjust the angle, make the water drop level 409 in a horizontal state, tighten the ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com