Method for producing and using calcium based rare earth composite catalyst for accelerating pulverized coal burning

A rare earth composite and production method technology is applied in the production and application fields of calcium-based rare earth composite catalysts, which can solve the problems of difficult recovery and regeneration of coal-fired catalysts, and achieve the effects of good catalytic combustion-supporting effect, less dosage and simple production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

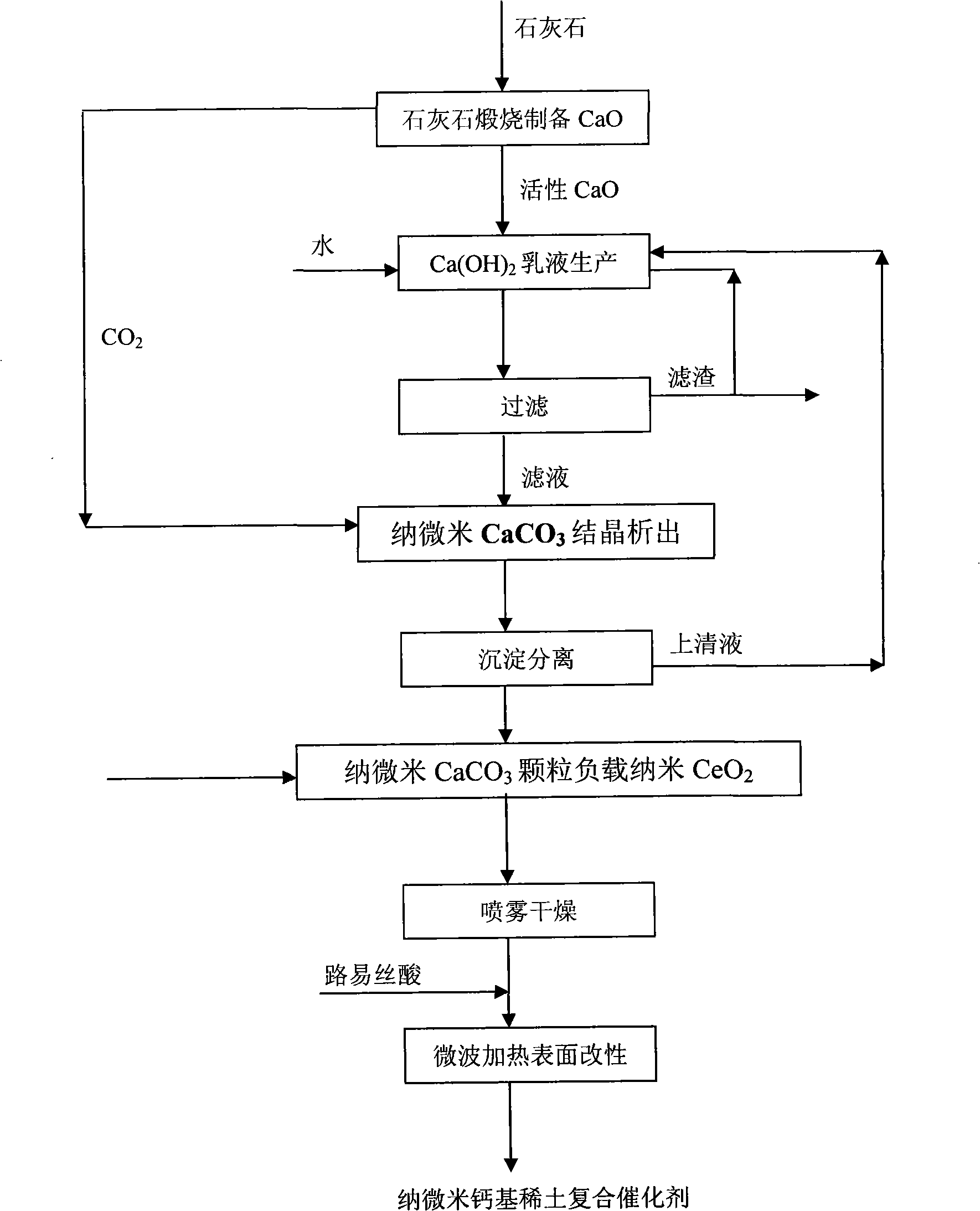

Method used

Image

Examples

Embodiment 1

[0022] The laboratory uses stainless steel as a reactor, adds 10 liters of water, and continuously adds chemical reagent CaO powder under stirring conditions until CaO no longer dissolves. The undissolved particles were then removed with filter paper to obtain Ca(OH) 2 saturated aqueous solution. Ca(OH) 2 Saturated aqueous solution is added to a vertical columnar glass reactor with a diameter of 100mm and a height of 1500mm, and CO is bubbled in at a rate of 500mL / min from a position 400mm from the bottom of the reactor. 2 Bubble until no new sediment is formed. After standing and settling for about 2 hours, the supernatant of the reactor was sucked off (the laboratory did not recycle), and the remaining slurry was added to a solution containing 3g nano-CeO 2 The suspension slurry was stirred for 30 minutes, and then spray-dried, and the spray-drying temperature was set at 250°C. The above process obtained CaCO 3 Negative CeO 2 Add 0.15 g of Lewis acid to 19 g of the pow...

Embodiment 2

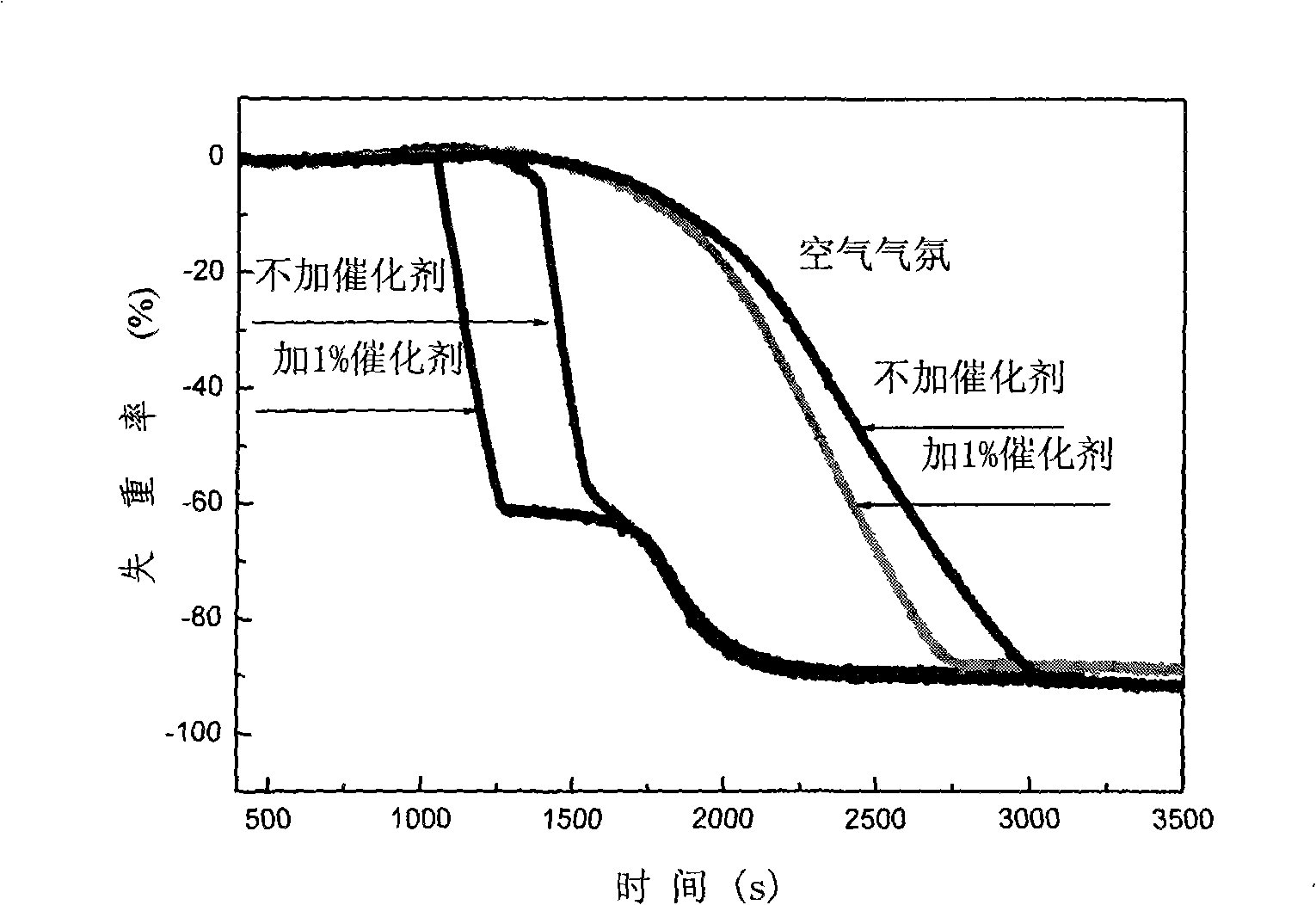

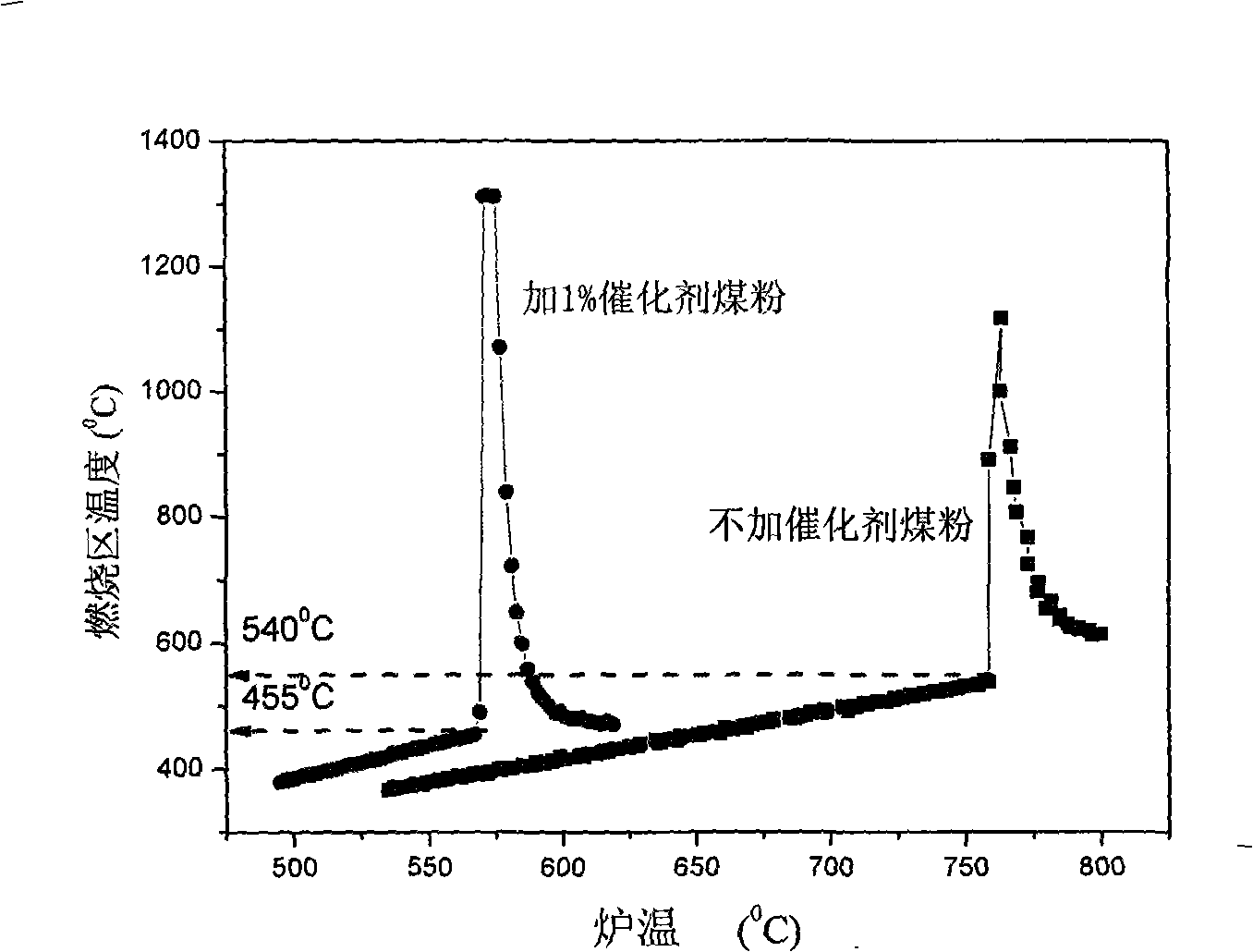

[0027] Using the catalyst production method of the present invention, an industrial production line has been established to produce nano-micron CaCO 3 Negative CeO 2 The calcium-based rare earth composite catalyst, the main component of which is CaCO 3 76%±1%, CeO 2 20%±0.5%, Ca(HO) 2 2% ± 0.2%, CaO 1.5% ± 0.2%, catalyst particle size D 50 is 2.7 microns, and the surface electronegativity of the catalyst particles is +23ev. The catalyst was applied to blast furnace coal injection to catalyze combustion, and the following test results were obtained:

[0028]1. In a steel plant with a 200 cubic meter blast furnace, the amount of coal injected per ton of iron is about 130kg, the temperature of the hot air is about 1190°C, and the type of coal is anthracite. The plant uses a medium-speed mill for pulverized coal production, and the amount of catalyst added is controlled at 0.5% of the raw coal delivery speed. The catalyst addition method adopts a quantitative screw continuous...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com