Hard coal seam mining method for balancing energy induced plastic damage and preventing and controlling dynamic damage and experimental device

A technology that induces plasticity and coal seam, applied in the direction of applying repeated force/pulsation force to test the strength of materials, ground mining, earth square drilling, etc., can solve problems such as dynamic damage and pick wear, so as to avoid dynamic damage and increase service life , The effect of increasing the speed of coal mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0037] A hard coal seam mining method that balances energy-induced plastic failure and prevents dynamic failure, comprising the following steps:

[0038] Step 1. An array of energy compensation holes is set on the mining face of the hard coal seam, namely: the energy compensation holes are arranged in rows and columns, and the energy compensation holes arranged in rows and columns form an array; an energy compensation device is arranged in each energy compensation hole, The energy compensation device includes a heating device and a refrigeration device; according to the energy compensation hole array, the coal wall is divided into several coal wall units corresponding to the energy compensation hole array;

[0039] The energy distribution of the coal wall is monitored by setting a rock burst monitoring system, and stress collection holes are arranged in each coal wall unit. The stress collection holes are arranged in rows and columns, and the stress collection holes arranged in...

specific Embodiment approach 2

[0052] Embodiment 2: The coal seam brittleness energy value of different hard coal seams is different, which is related to the hardness of the mined coal seam, so the coal seam brittleness energy value needs to be determined through experiments. The determination process of the coal seam embrittlement energy value described in the present embodiment is as follows:

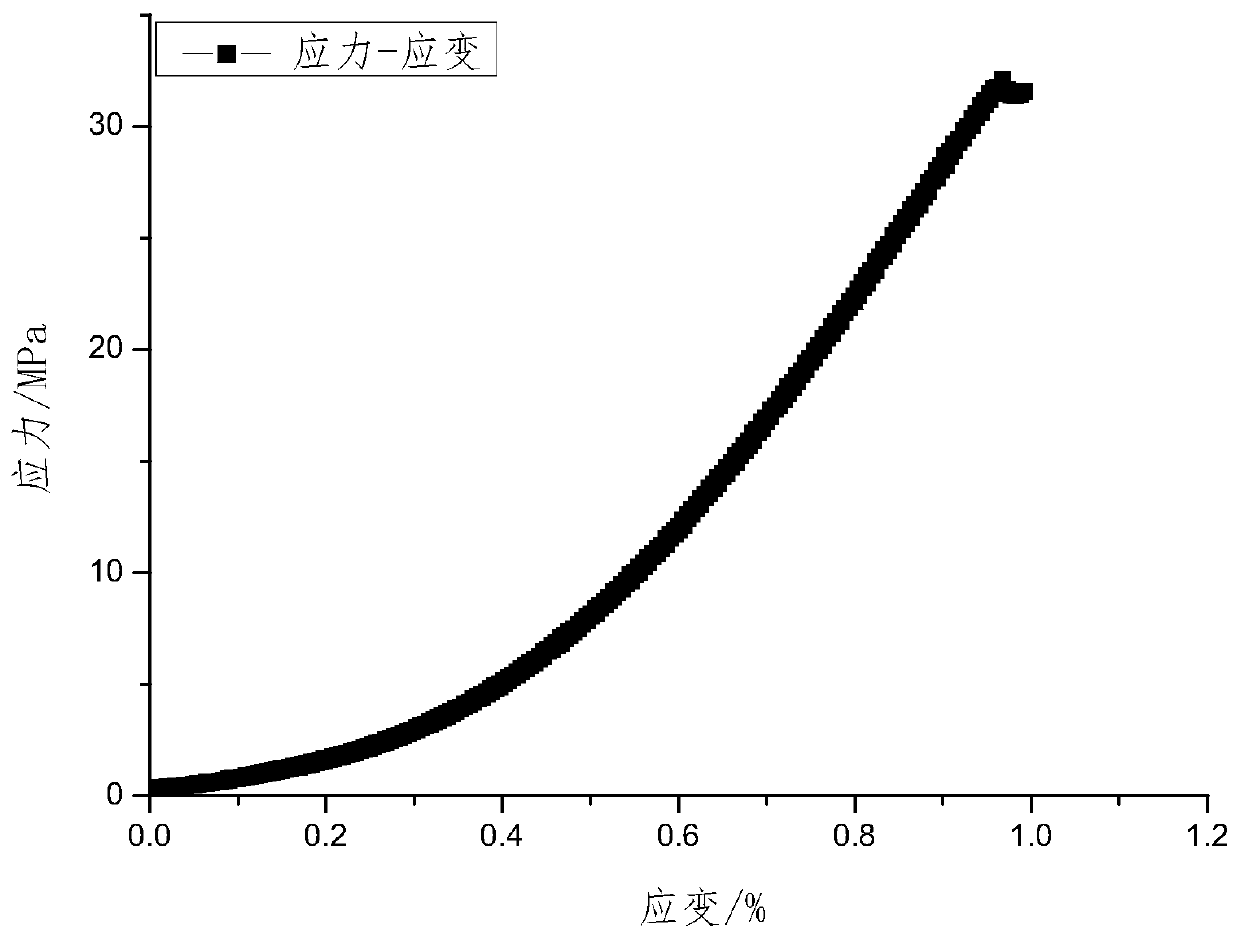

[0053] According to Part 7 "Measurement of Uniaxial Compressive Strength and Calculation Method of Softening Coefficient (GB / T 23561.7-2009)" of "Measurement Methods of Physical and Mechanical Properties of Coal and Rock", the coal samples of hard coal seams were collected and made into 50×50×100mm The standard sample is subjected to a pressure test; when the standard sample cracks, such as figure 1 The coal sample shown, according to the test applied pressure F and crack displacement s 1 Get the coal seam brittle fracture energy value Q 1 =∫Fds 1 , where the crack displacement s 1 is the corresponding displace...

specific Embodiment approach 3

[0057] The determination process of the coal seam embrittlement energy value described in the present embodiment is as follows:

[0058] According to Part 7 "Measurement of Uniaxial Compressive Strength and Calculation Method of Softening Coefficient (GB / T 23561.7-2009)" of "Measurement Methods of Physical and Mechanical Properties of Coal and Rock", the coal samples of hard coal seams were collected and made into 50×50×100mm The standard sample is subjected to a pressure test. When the standard sample cracks, the pressure F and the crack displacement s applied according to the test 1 Get the brittle fracture energy value Q 1 =∫Fds 1 , where the crack displacement s 1 is the corresponding displacement from when the pressure loading device contacts the standard sample to when the standard sample cracks;

[0059] Carry out several groups of experiments, and take the smallest brittle energy value among the brittle energy values obtained by several groups of experiments as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com