Steeply-inclined extra-thick hard coal seam blasting and large-diameter drilling combined pressure relief method

A large-diameter, steeply inclined technology, used in earth-moving drilling, special mining, surface mining, etc., can solve the problems of inability to realize full pressure relief of coal seam pressure, low recovery rate, and unmatched working face field conditions in the parameters of relief measures. , to achieve the effect of reducing stress concentration and impact risk, improving recovery rate, and good pressure relief effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

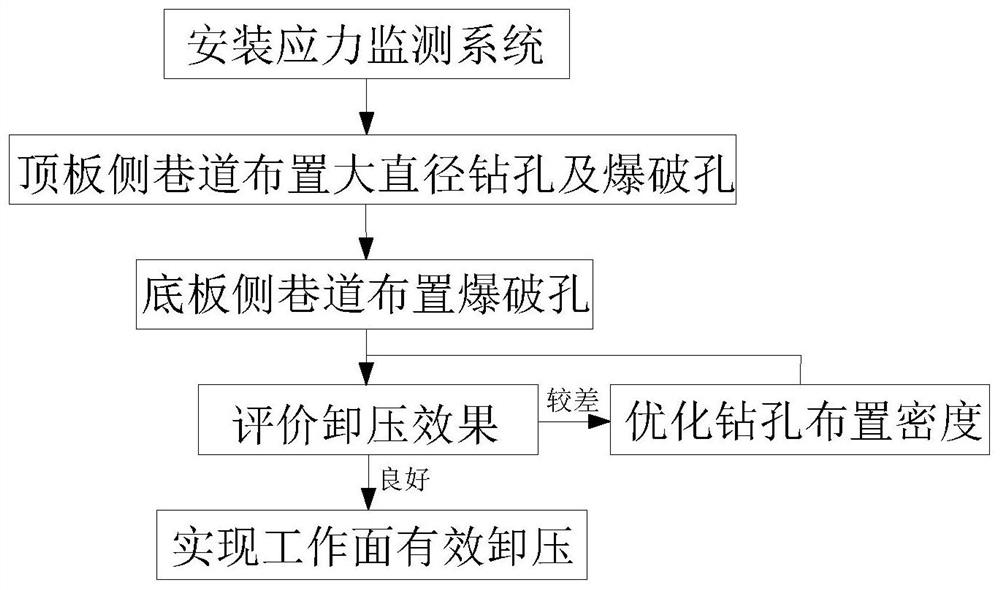

[0030] Such as figure 1 As shown, the combined pressure relief method of a steeply inclined extra-thick hard coal seam blasting and large-diameter drilling specifically includes the following steps:

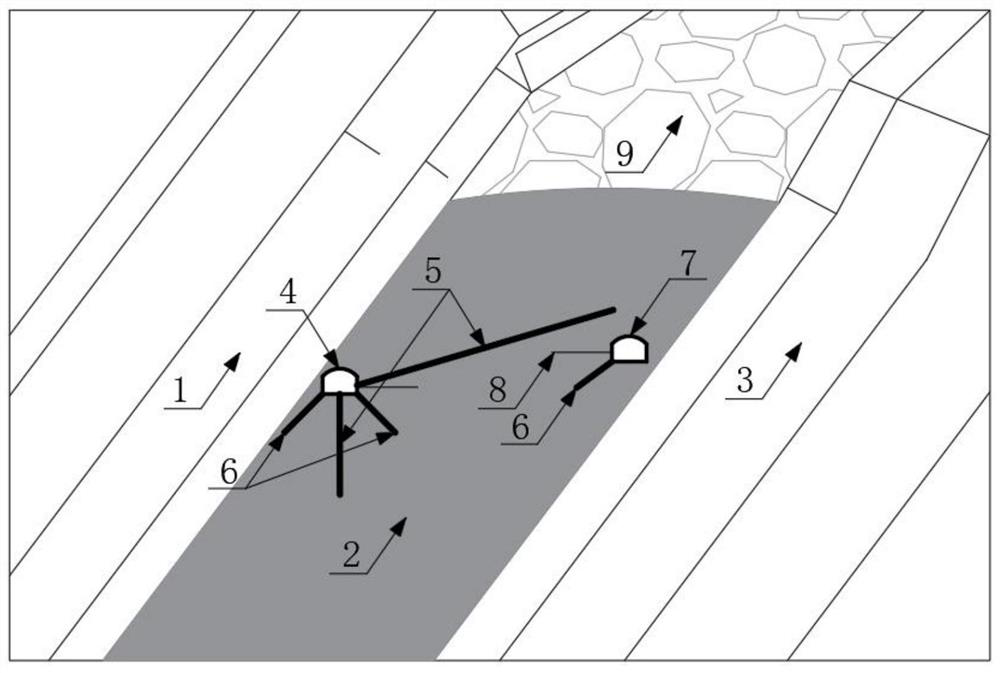

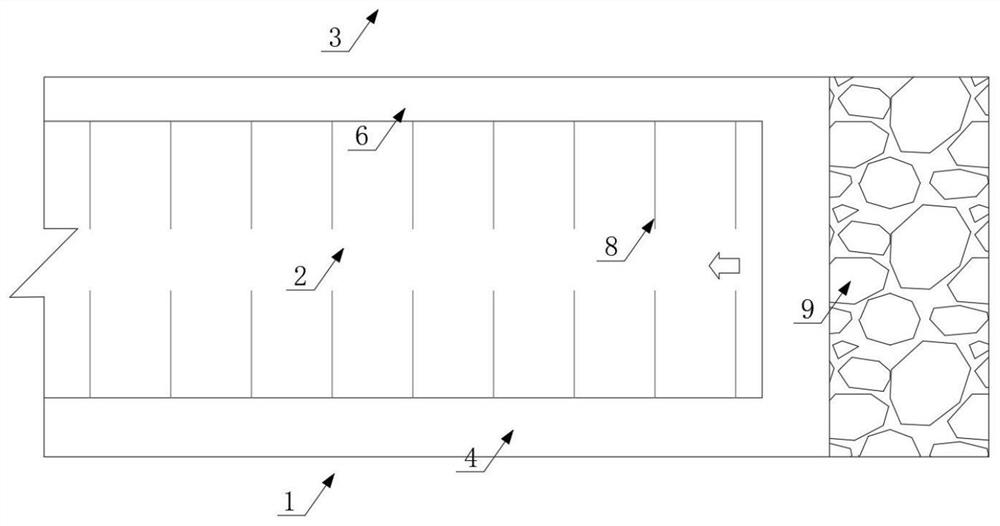

[0031] S1, during the mining process of steeply inclined extra-thick hard coal seams, the roadway 4 on the roof side and the roadway 7 on the floor side are arranged in staggered layers, and multiple drilling stress gauges 8 are installed on the two roadways and cover the entire roadway to monitor the surrounding rock stress of the roadway Variety;

[0032] S2. According to the mechanical properties of the coal body and the roof and floor of the coal seam, determine the parameters of the blast hole 6 and the large-diameter drill hole 5, the hole diameter, the hole depth, the distance, and the parameters of the position from the floor, and arrange the large-diameter drill hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hole depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com