Porous control method for blasting softening of hard top plate and coal seam

A hard roof and controlled blasting technology, which is applied in blasting, earthwork drilling, ground mining, etc., can solve the problems of crack expansion and extension, such as outstanding uncertainty, uncertainty, and automatic collapse, so as to reduce the aperture and drill The effect of the number of holes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

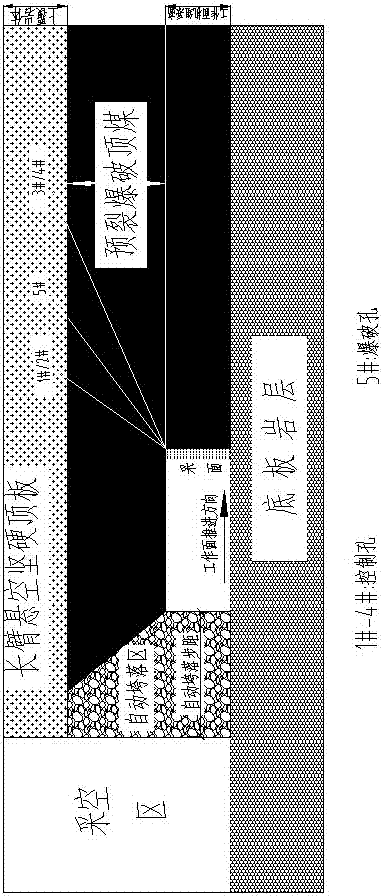

[0033] Such as figure 1 As shown, this technology aims at loosening the top coal by means of pre-splitting blasting when the top coal is difficult to put in the mining process due to the hard coal quality.

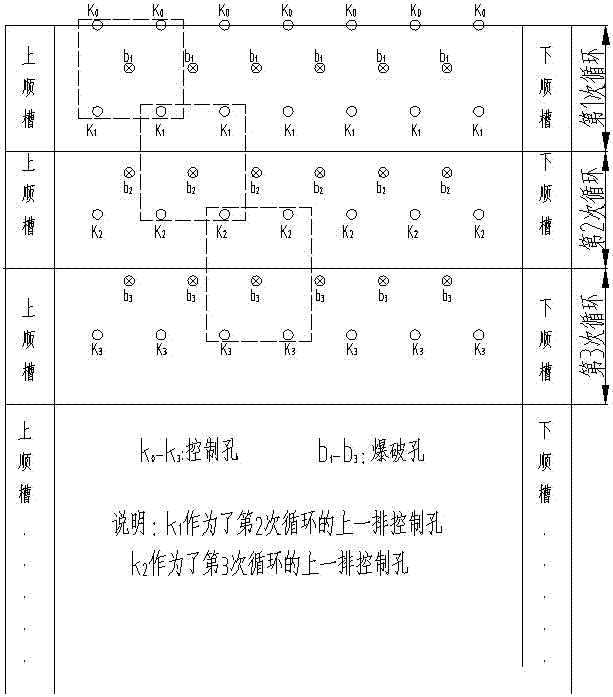

[0034] First, arrange three rows along the entire length of the working face, divided into groups of blastholes (1 # ~5 # Drilling), in order to facilitate blasting holes and charge charges and avoid impact on production, it is generally selected between the coal wall (old empty side) 0.5 ~ 2m (the position of the front beam of the bracket), the roof is complete, and the cracks are relatively undeveloped Drilling between frames. The upper and lower sets of boreholes spaced apart from each other are used as blasting control holes (1 # ~4 # is the control hole), the middle group is 5 # Drilling holes are used as blast holes, please refer to the specific layout figure 1 .

[0035] In the process of construction drilling, each blasting parameter must be reasonably contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com