Freeze-resistant twisted paper and production method thereof

A kind of kink and preparation process technology, applied in papermaking, wrapping paper, paper coating and other directions, can solve the problems of inability to meet the packaging of popsicles, brittle and broken, and the packaging paper is hard, and achieve excellent softness and tear strength, prevent brittle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

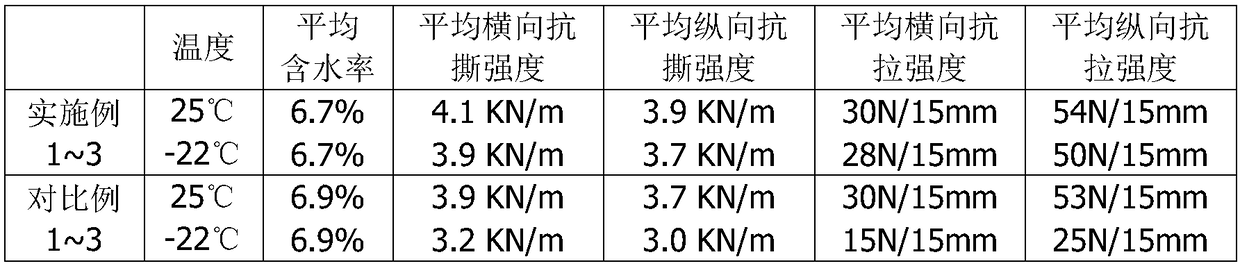

Examples

Embodiment 1

[0031] A kind of anti-freezing twisting paper is prepared through the following steps:

[0032] 1. Base paper substrate: long-fiber leaf-increasing pulp base paper is selected as the paper substrate. The weight of paper is 24-45 grams per square meter, and the technical indicators of base paper are as follows:

[0033] Moisture content 5.2%

[0034] Transverse tear strength 3.5KN / m

[0035] Longitudinal tear strength 3.3KN / m

[0036] Transverse tensile strength 25N / 15mm

[0037] The longitudinal tensile strength is 47N / 15mm.

[0038] 2. Printing: Printing is carried out on the upper surface of the paper base layer, that is, the vacuum aluminized layer.

[0039] 3. Penetration: Prepare the penetrant according to the formula of 24% glycerin, 16% D-mannitol, 4% sorbitol, and 56% water, and use the dip coating method to infiltrate, that is, the paper is completely immersed in the penetrant, and the paper is soaked at 120 m / The paper passes through the penetrating agent at a...

Embodiment 2

[0043] A kind of anti-freezing twisting paper is prepared through the following steps:

[0044] 1. Base paper substrate: long-fiber leaf-increasing pulp base paper is selected as the paper substrate. The weight of paper is 24-45 grams per square meter, and the technical indicators of base paper are as follows:

[0045] Moisture content 5.2%

[0046] Transverse tear strength 3.5KN / m

[0047] Longitudinal tear strength 3.3KN / m

[0048] Transverse tensile strength 25N / 15mm

[0049] The longitudinal tensile strength is 47N / 15mm.

[0050] 2. Printing: Printing is carried out on the upper surface of the paper base layer, that is, the vacuum aluminized layer.

[0051] 3. Penetration: Prepare the penetrant according to the formula of 30% glycerin, 20% D-mannitol, 3% sorbitol, and 47% water, and use the dip coating method to infiltrate, that is, the paper is completely immersed in the penetrant, and the paper is soaked at 140 m / The paper passes through the penetrating agent at a...

Embodiment 3

[0055] A kind of anti-freezing twisting paper is prepared through the following steps:

[0056] 1. Base paper substrate: long-fiber leaf-increasing pulp base paper is selected as the paper substrate. The weight of paper is 24-45 grams per square meter, and the technical indicators of base paper are as follows:

[0057] Moisture content 5.2%

[0058] Transverse tear strength 3.5KN / m

[0059] Longitudinal tear strength 3.3KN / m

[0060] Transverse tensile strength 25N / 15mm

[0061] The longitudinal tensile strength is 47N / 15mm.

[0062] 2. Printing: Printing is carried out on the upper surface of the paper base layer, that is, the vacuum aluminized layer.

[0063] 3. Penetration: Prepare the penetrant according to the formula of 36% glycerin, 24% D-mannitol, 2% sorbitol, and 38% water, and use the dip coating method to infiltrate, that is, the paper is completely immersed in the penetrant, and the paper is soaked at 160 m / The paper passes through the penetrating agent at a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com