Microcapsule humectant for cigarettes, preparation method of microcapsule humectant and application of microcapsule humectant

A technology of microcapsules and humectants, applied in the field of tobacco processing, can solve the problems of aroma loss, demulsification, easy moisture absorption, etc., achieves a simple and easy preparation method, increases the sweetness and moisturizing feeling, and increases the original aroma of tobacco Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] S1. water bath 30 ℃, under stirring condition, get 1 weight part of chitosan and join in 98.2 weight parts of deionized water, after stirring well, add 0.8 weight part of glacial acetic acid, stir until dissolving, obtain 100 weight parts of mass concentration 1% Chitosan solution;

[0061] S2. Add 2 parts by weight of emulsifier sucrose ester in the mass concentration 1% chitosan solution obtained in S1, its HLB value is 16, after stirring and dissolving, increase the temperature of the water bath to 70°C, add 15 parts by weight of oily substance, and stir until Melt the oily substance, and use a homogenizer to emulsify at a speed of 10000 r / min, emulsify for 10 min, cool to room temperature, and obtain an O / W emulsion; the mass formula percentage of the oily substance is: ethyl myristate: 20% , Yunnan Tobacco Volatile: 5%, Liquid Paraffin: 35%, Palm Wax 40%.

[0062] S3. Place the O / W emulsion obtained in S2 in an air atomizer to form 10-200 μm droplets, spray it int...

Embodiment 2

[0064] S1. Water bath at 45°C, under stirring, take 3 parts by weight of chitosan and add it to 94.6 parts by weight of deionized water, stir well, add 2.4 parts by weight of glacial acetic acid, stir until dissolved, and obtain 100 parts by weight of shell with a mass concentration of 3%. polysaccharide solution;

[0065] S2. Add 1.5 parts by weight of emulsifier sucrose ester to the mass concentration 3% chitosan solution obtained in S1, and its HLB value is 15. After stirring and dissolving, increase the temperature of the water bath to 80° C., add 12 parts by weight of oily substances, and stir until Melt the oily substance, and use a homogenizer to emulsify at a speed of 15000 r / min, emulsify for 20 min, cool to room temperature, and obtain an O / W emulsion; the mass formula percentage of the oily substance is: ethyl myristate: 30% , Zimbabwe tobacco volatiles: 8%, liquid paraffin: 32%, palm wax: 30%.

[0066] S3. Place the O / W emulsion obtained in S2 in an air atomizer t...

Embodiment 3

[0068] S1. Water bath at 40°C, under stirring, take 5 parts by weight of chitosan and add it to 91 parts by weight of deionized water, stir well, add 4 parts by weight of glacial acetic acid, stir until dissolved, and obtain 100 parts by weight of shell with a mass concentration of 5%. polysaccharide solution;

[0069] S2. Add 0.05 parts by weight of emulsifier sucrose ester to the mass concentration 5% chitosan solution obtained in S1, and its HLB value is 11. After stirring and dissolving, increase the temperature of the water bath to 90° C., add 20 parts by weight of oily substances, and stir until Melt the oily substance and use a homogenizer to emulsify at a speed of 20,000 r / min, emulsify for 30 min, cool to room temperature, and obtain an O / W emulsion; the mass formula percentage of the oily substance is: ethyl myristate: 35% , Turkish tobacco volatiles: 10%, liquid paraffin: 30%, palm wax 25%.

[0070] S3. Place the O / W emulsion obtained in S2 in an air atomizer to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

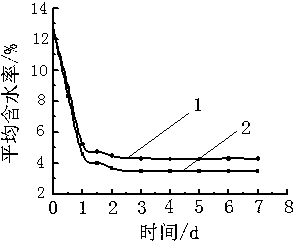

| Particle size | aaaaa | aaaaa |

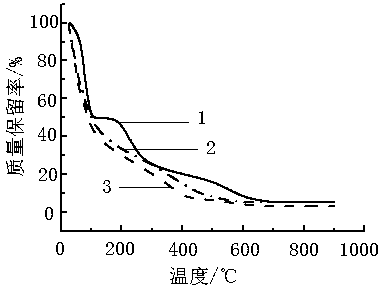

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com