Processing technology of sun-cured yellow tobacco alcohol composition for electronic cigarette and sun-cured yellow tobacco alcohol composition

A processing technology and composition technology, which can be applied to tobacco, tobacco preparation, tobacco processing and other directions, and can solve problems such as unhealthy health, sweet and greasy taste of electronic cigarettes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

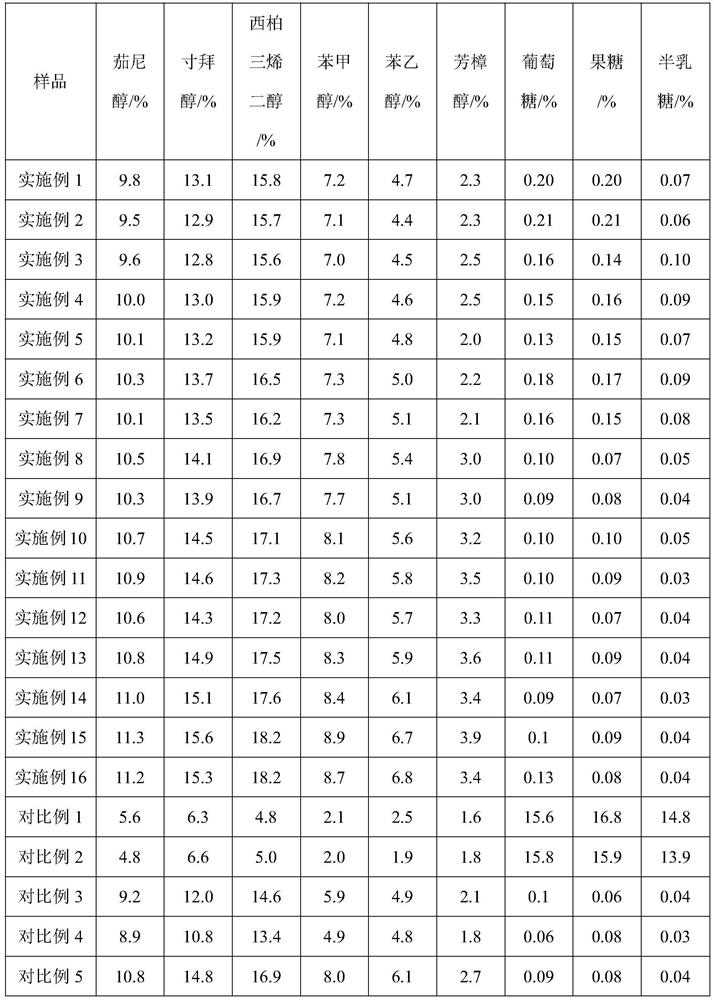

Examples

Embodiment 1

[0036] A processing technique of a yellow tobacco alcohol composition for electronic cigarettes, comprising the steps:

[0037] Step S1: get 10kg of yellowing smoke in the reactor, add the mixed solvent of ether and acetone with a volume ratio of 2:5, and the volume ratio of yellowing smoke and the mixed solvent is 1:6, and ultrasonically treat for 30min to obtain a mixture;

[0038] Step S2: heating the mixture to 35°C, refluxing for 2h, and concentrating to obtain a crude extract of yellow smoke;

[0039] Step S3: adding petroleum ether with a volume ratio of 1:30 to the crude extract of yellow tobacco, heating to 30° C., distilling for 5 hours, filtering and concentrating to obtain the crude tobacco extract of yellow tobacco;

[0040] Step S4: add the ethanol whose volume ratio is 1:5 to the alcoholic crude extract of Nicotiana japonica, be warming up to 45 DEG C, after stirring, leaving standstill and concentrating, adding and the alcoholic crude extract of tobacco yellow ...

Embodiment 2

[0043] A processing technology of the yellow tobacco alcohol composition for electronic cigarette, the difference between it and Example 1 is that the conditions of the processing technology are different.

[0044] A processing technique of a yellow tobacco alcohol composition for electronic cigarettes, comprising the steps:

[0045]Step S1: get 10kg of yellow smoke in the reactor, add the mixed solvent of ether and acetone with a volume ratio of 2:5, and the volume ratio of the yellow smoke and the mixed solvent is 1:7, and ultrasonically process 45min to obtain the mixture;

[0046] Step S2: heating the mixture to 38°C, refluxing for 2.5h, and concentrating to obtain a crude extract of yellow smoke;

[0047] Step S3: adding petroleum ether with a volume ratio of 1:30 to the crude extract of yellow tobacco, heating to 35° C., distilling for 5.5 h, filtering and concentrating to obtain the crude tobacco extract of yellow tobacco;

[0048] Step S4: add the ethanol whose volume...

Embodiment 3

[0051] A processing technology of the yellow tobacco alcohol composition for electronic cigarette, the difference between it and Example 1 is that the conditions of the processing technology are different.

[0052] A processing technique of a yellow tobacco alcohol composition for electronic cigarettes, comprising the steps:

[0053] Step S1: get 10kg of yellow-cured tobacco in the reactor, add the mixed solvent of ether and acetone with a volume ratio of 2:5, and the volume ratio of the crude extract of the yellow-cured tobacco to the mixed solvent is 1:8, and ultrasonically treat it for 60min to obtain a mixed solvent. material;

[0054] Step S2: heating the mixture to 40°C, refluxing for 3 hours, and concentrating to obtain a crude extract of yellow smoke;

[0055] Step S3: adding petroleum ether with a volume ratio of 1:30 to the crude extract of yellowing tobacco, heating to 40° C., distilling for 6 h, filtering and concentrating to obtain a crude extract of yellowing to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com