Water-based cutting fluid of hard brittle material and preparation method of water-based cutting fluid

A technology for hard and brittle materials and cutting fluids, applied in the petroleum industry, lubricating compositions, etc., can solve problems such as increased mortar viscosity, unstable cutting process, difficult recycling, etc., and achieves no influence on viscosity changes, superior cooling performance, and dispersion lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

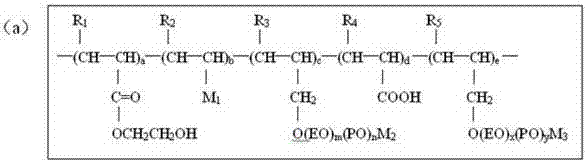

[0047] Configure 1000g water-based cutting fluid

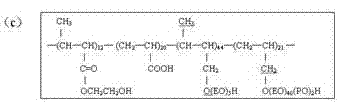

[0048] Take 8g of fumed silica, disperse in 790g of diethylene glycol, and stir at 30~40°C for 10 minutes until the dispersion is uniform to obtain A 1 Item: Dissolve 2g of water-retaining agent (molecular formula such as b) in 200g of deionized water, stir at 20°C for 15-30 minutes to obtain B 1 item; put A 1 with B 1 After the items are mixed, add the remaining deionized water and continue to stir for 1 hour to obtain the water-based cutting fluid 1.

[0049]

[0050]

Embodiment 2

[0052] Configure 1000g water-based cutting fluid

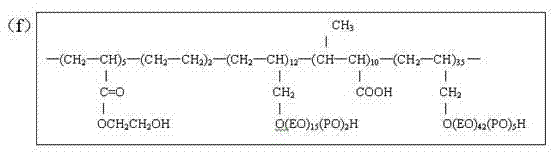

[0053] Take 1g of fumed silica, disperse in 800g of triethylene glycol, stir at 30~40°C for 60 minutes until the dispersion is uniform to obtain A 2 Item: Dissolve 0.8g of water-retaining agent (molecular formula as c) in 198g of deionized water, stir at 40°C for 15-30 minutes to obtain B 2 item; put A 2 with B 2 Item and 0.2g of EL-10 were mixed, then added the remaining deionized water and continued to stir for 3 hours to obtain water-based cutting fluid 2.

[0054]

Embodiment 3

[0056] Configure 1000g water-based cutting fluid

[0057] Take 9g of fumed silica, disperse in 660g of propylene glycol, and stir at 30~40°C for 30 minutes until the dispersion is uniform to obtain A 3 Item: Dissolve 0.6g of water-retaining agent (molecular formula such as d) in 330g of deionized water, stir at 30°C for 15-30 minutes to obtain B 3 item; put A 3 with B 3 Item and 0.4g of EL-15 were mixed, then added the remaining deionized water and continued to stir for 2 hours to obtain water-based cutting fluid 3.

[0058]

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com