Method for drying hydrocortisone sodium succinate asepsis powder

A technology of hydrocortisone sodium succinate and drying method, applied in the fields of organic chemistry, steroids, spray evaporation, etc., can solve the problems of dust pollution, material overheating, discontinuous production process, etc., to ensure uniform drying and smooth drying. The effect of rotating airflow and eliminating dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

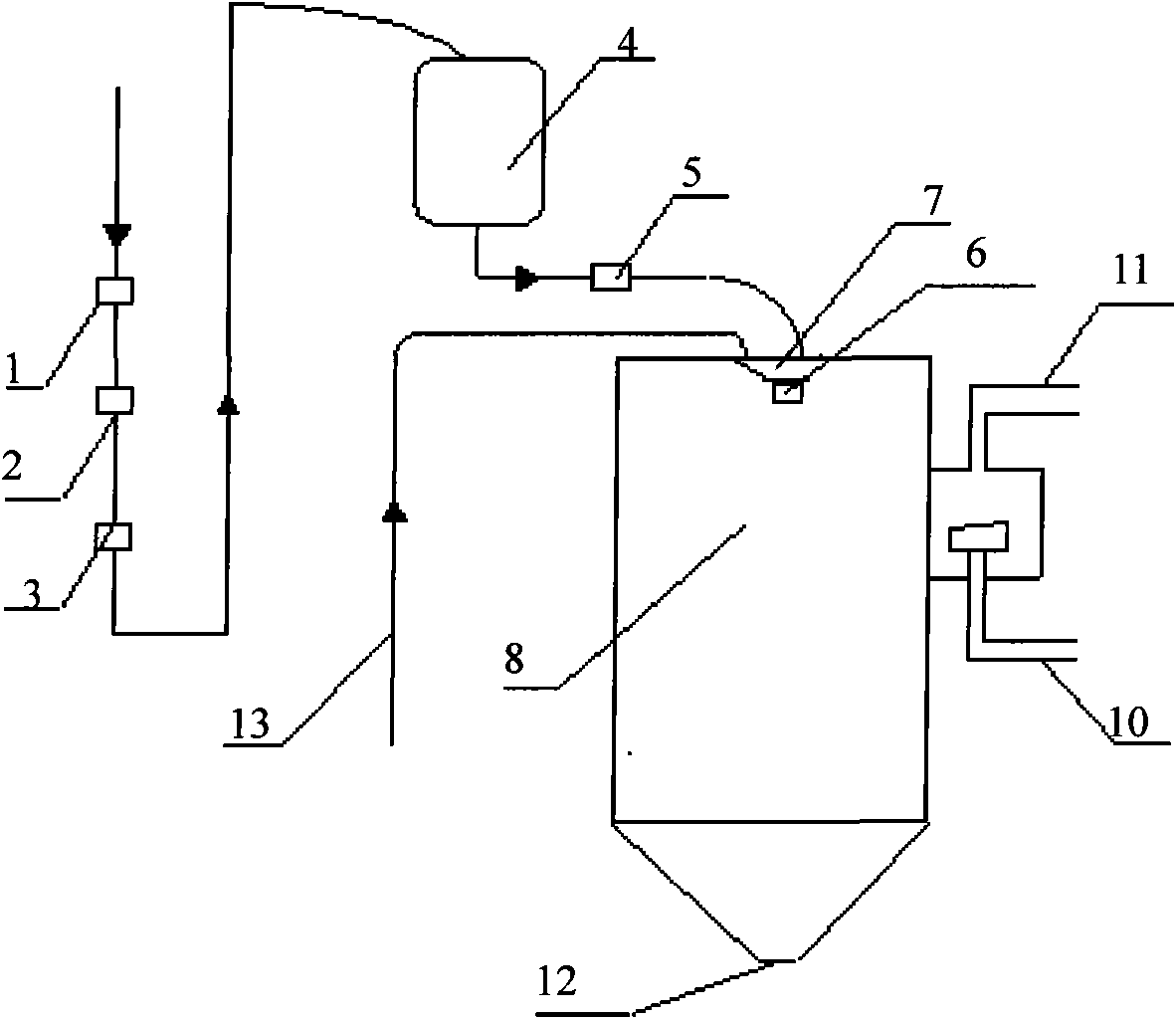

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

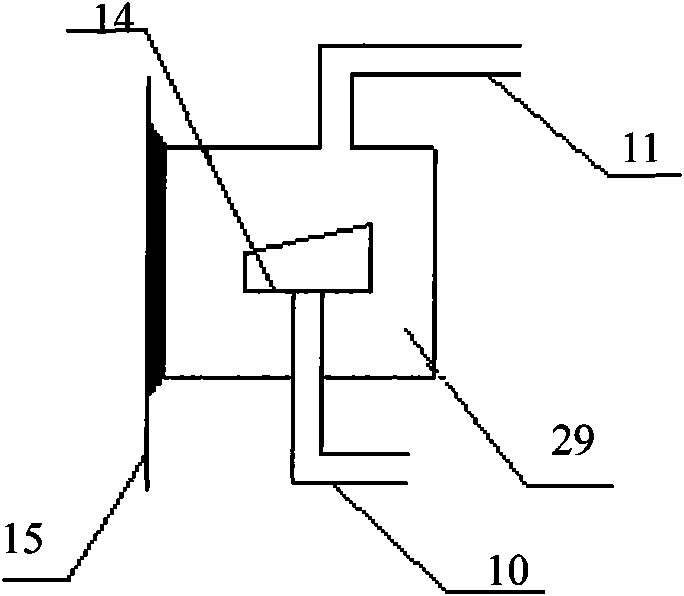

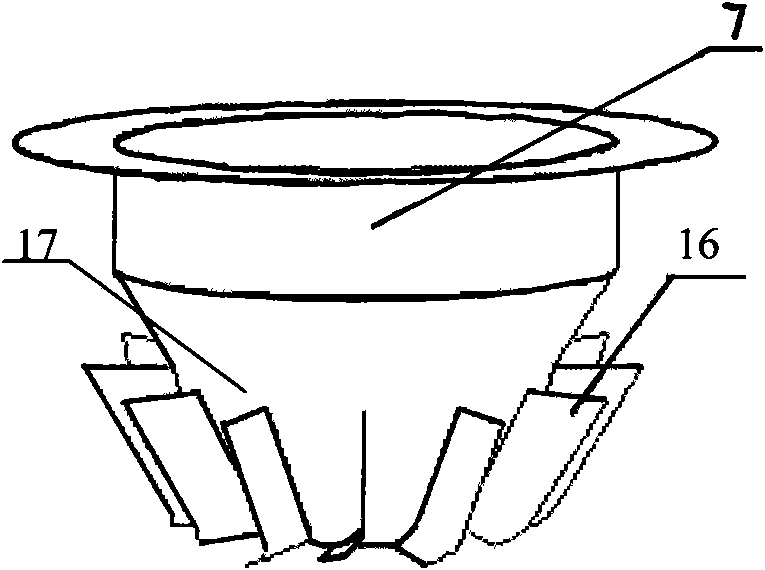

[0021] Such as figure 1 Shown, a kind of drying method of hydrocortisone sodium succinate aseptic powder, comprises the steps: the hydrocortisone sodium succinate aqueous solution that concentration is 100g / L-200g / L is input temperature control tank 4 after filtering In the process, after passing through the second fine filter 5, it is input into the spray drying tower 8, after being atomized by the atomizer 6, it is contacted with hot sterile air for drying, and the hot sterile air is input into the spray drying tower from the air inlet pipe 13, The top of the spray drying tower is provided with a hot air distributor 7, the hot air distributor includes an inner pipe 17 and an air deflector 16, the lower part of the air deflector is bent to one side, and the outer surface of the spray drying tower wall is provided with a tower wall shock absorber. Beating device, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com