Ultra-fine kaolin four-stage powder making equipment and ultra-fine kaolin and four-stage powder making production process of ultra-fine kaolin

A technology of ultra-fine kaolin and powder-making equipment, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high energy consumption and high production cost of ultra-fine kaolin, achieve low energy consumption and wide application range , The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

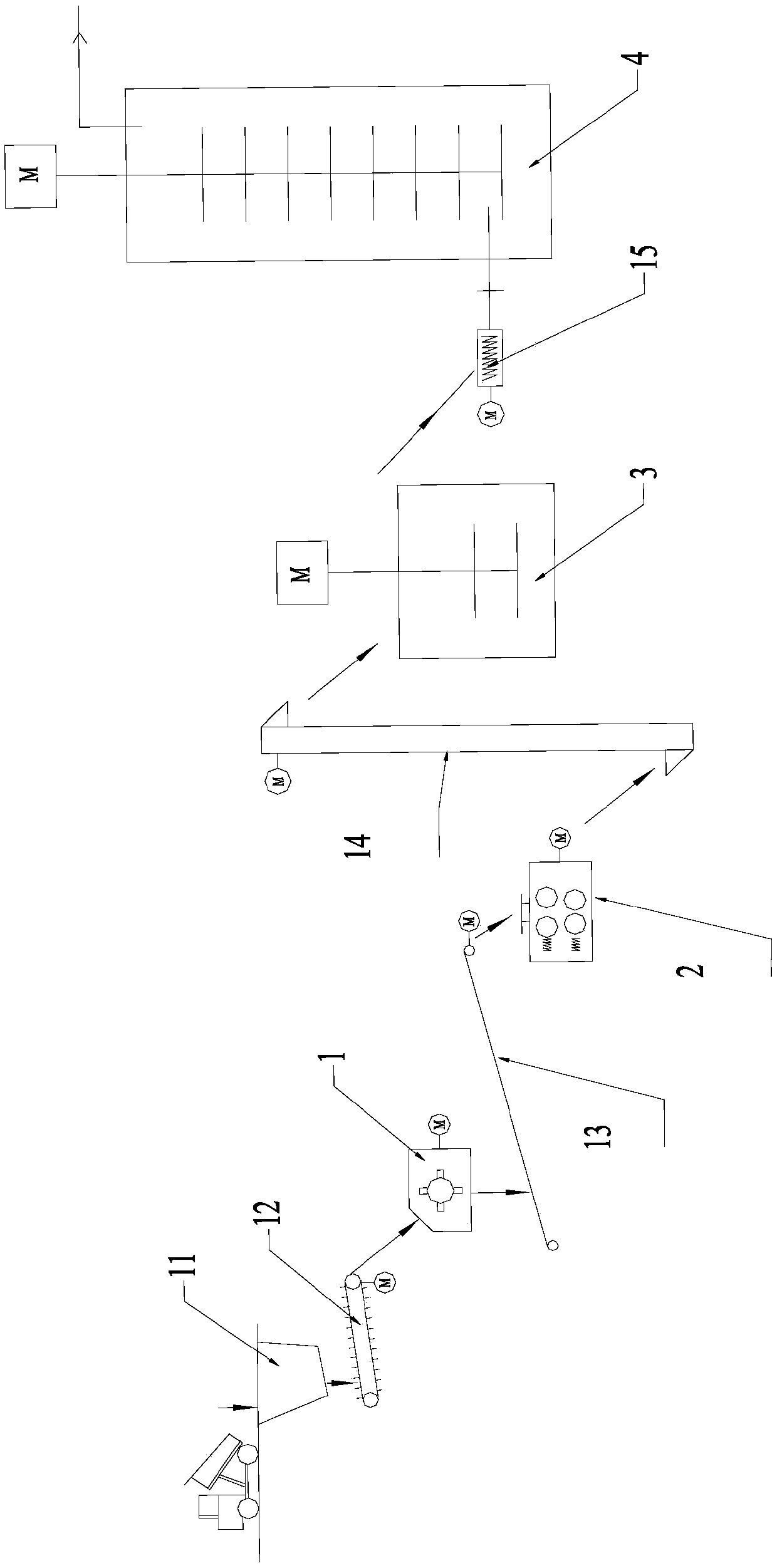

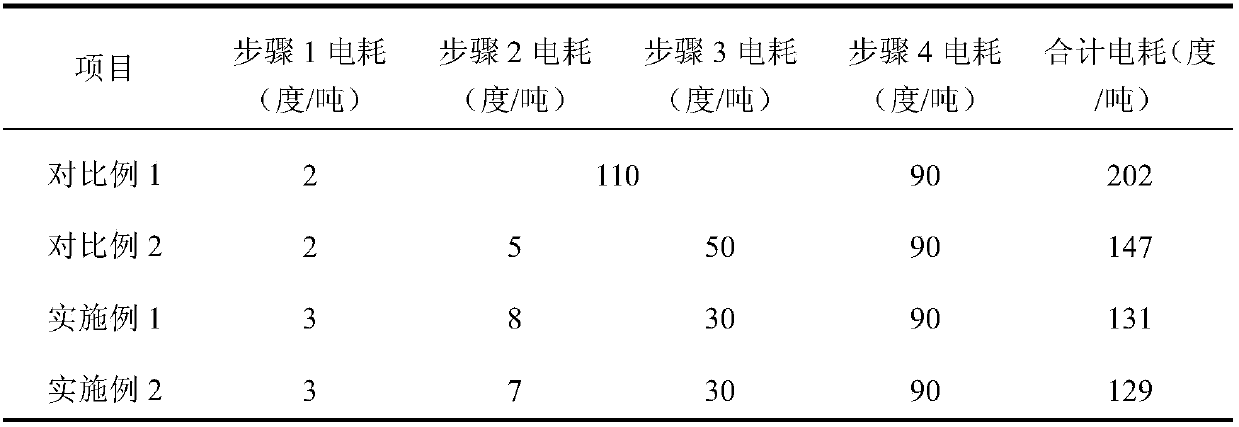

[0042] (1) Load the raw ore into the hopper 11 through the plate feeder 12 into the single-stage hammer crusher for crushing, and obtain at least 91% of coarse materials with a particle size of less than 30mm;

[0043] (2) The coarse material in step (1) enters the filtering device for filtering, and the filtered coarse material enters the four-roll crusher through the belt conveyor 13 for crushing, and at least 90% of solid particles with a particle size of less than 1 mm are obtained;

[0044] (3) The solid particles in step (2) enter the screening device for screening, and the qualified solid particles enter the vertical ball mill through the bucket elevator 14. The feeding device and the water injection device control the ratio of solid particles to water. The solid content is 50%, the dispersant is added, and the dispersant is 0.1% of the total amount, and the grinding is performed to obtain at least 91% of the slurry with a particle size of less than 325 mesh;

[0045] (4) The ...

Embodiment 2

[0047] (1) Load the raw ore into the hopper 11 through the plate feeder 12 into the single-stage hammer crusher for crushing, and obtain at least 92% of coarse materials with a particle size of less than 30mm;

[0048] (2) Enter the coarse material in step (1) into the filter device for filtration, and the filtered coarse material enters the four-roll crusher through the belt conveyor 13 for crushing, and at least 91% of solid particles with a particle size of less than 1 mm are obtained;

[0049] (3) The solid particles in step (2) enter the screening device for screening, and the qualified solid particles enter the vertical ball mill through the bucket elevator 14. The feeding device and the water injection device control the ratio of solid particles to water. The solid content is 46%, and the dispersant is added. The dispersant is 0.2% of the total amount. After grinding, at least 93% of the slurry with a particle size of less than 325 mesh is obtained;

[0050] (4) The slurry in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com