Large-grain-size spherical silver powder and preparation method thereof

A large particle size, silver powder technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of narrow particle size dispersion range, rarely mention the preparation process of large particle size spherical silver powder, etc. High tap density and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

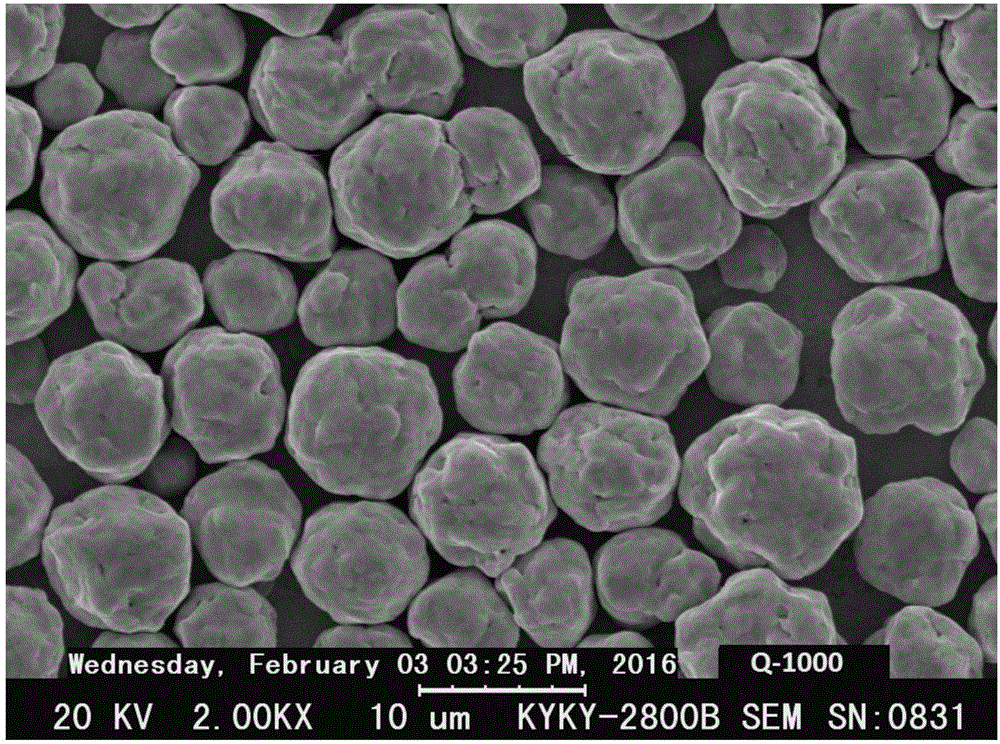

Embodiment 1

[0033] The large particle size spherical silver powder of the present embodiment and preparation method thereof, the steps are as follows:

[0034] (1) Take silver nitrate solid 1kg and place it in the batching bucket, add 4L of pure water to dissolve; add pure water at last to dilute the system to 5L, and make a silver nitrate system with a silver nitrate content of about 200g / L;

[0035] (2) Weigh 0.6 kg of ascorbic acid and add 18 L of pure water to dissolve, add 5 g of pre-dissolved sodium lauryl sulfate; stir evenly and add pure water to dilute the system to 20 L, stir evenly to form a reduction system;

[0036] (3) Adjust the temperature of the silver nitrate system and the reduction system to 20° C., using the reduction system as the matrix, and at a stirring speed of 80 r / min, add the silver nitrate system to the reduction system within 1 min for reaction;

[0037] (4) After the reaction is completed and aged for 5 minutes, the silver powder is moved to a filter tank f...

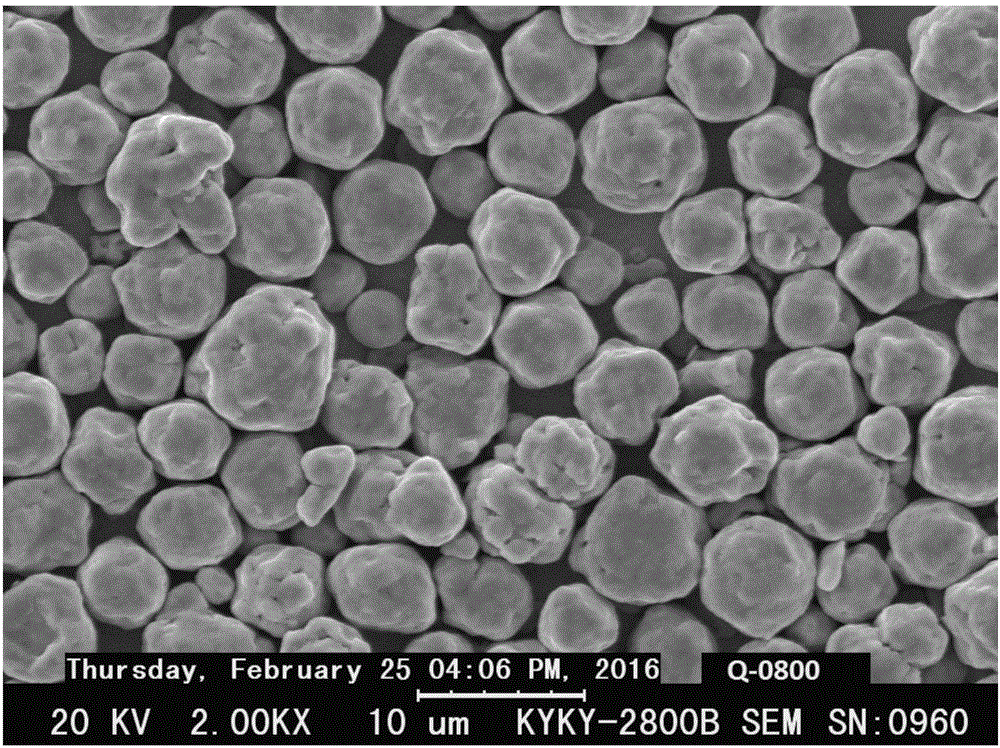

Embodiment 2

[0040] The large particle size spherical silver powder of the present embodiment and preparation method thereof, the steps are as follows:

[0041] (1) Take silver nitrate solid 1kg and place it in the batching bucket, add 4L of pure water to dissolve; add pure water at last to dilute the system to 5L, and make a silver nitrate system with a silver nitrate content of about 200g / L;

[0042] (2) Weigh 0.6 kg of ascorbic acid and add 18 L of pure water to dissolve, add 5 g of pre-dissolved sodium oleate; stir evenly and add pure water to dilute the system to 20 L, stir evenly to form a reduction system;

[0043] (3) Adjust the silver nitrate system and the reduction system to 20°C, take the reduction system as the matrix, and add the silver nitrate system to the reduction system within 1 min at a stirring speed of 80r / min for reaction;

[0044] (4) After the reaction is completed and aged for 5 minutes, the silver powder is moved to the filter tank for cleaning and filtration unt...

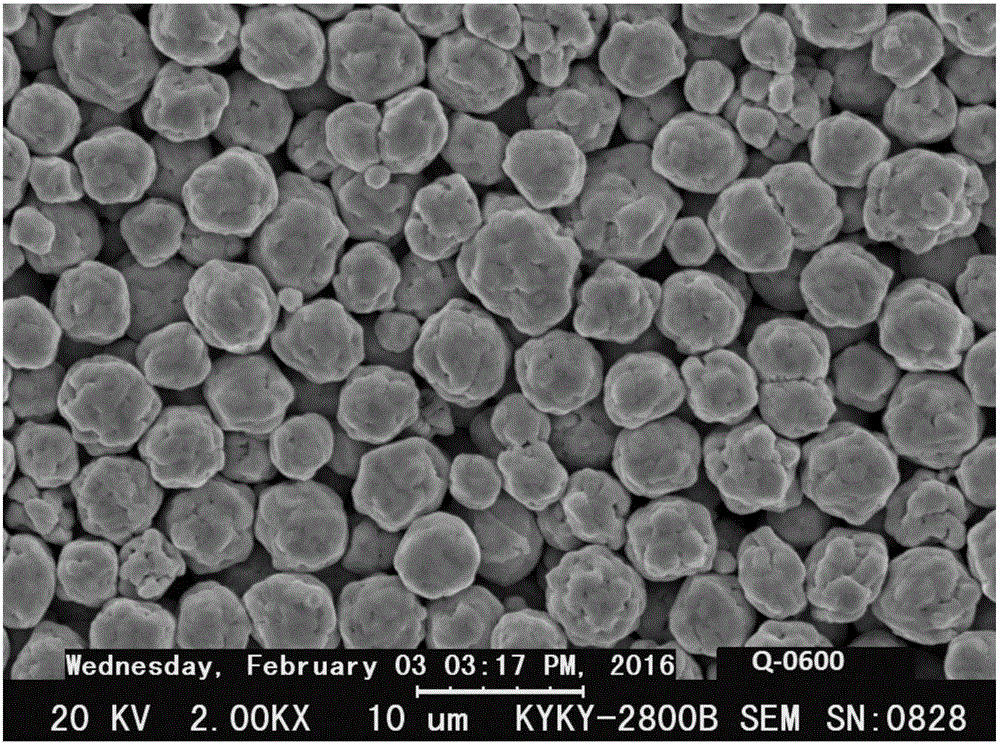

Embodiment 3

[0047] The large particle size spherical silver powder of the present embodiment and preparation method thereof, the steps are as follows:

[0048] (1) Take silver nitrate solid 1kg and place it in the batching bucket, add 4L of pure water to dissolve; add pure water at last to dilute the system to 5L, and make a silver nitrate system with a silver nitrate content of about 200g / L;

[0049] (2) Weigh 0.6 kg of ascorbic acid and add 18 L of pure water to dissolve, add 5 g of pre-dissolved calcium lignosulfonate; stir evenly and add pure water to dilute the system to 20 L, stir evenly to form a reduction system;

[0050] (3) Adjust the silver nitrate system and the reduction system to 15°C, take the reduction system as the matrix, and add the silver nitrate system to the reduction system within 1 min at a stirring speed of 80r / min for reaction;

[0051](4) After the reaction is completed and aged for 5 minutes, the silver powder is moved to a filter tank for cleaning and filtrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com