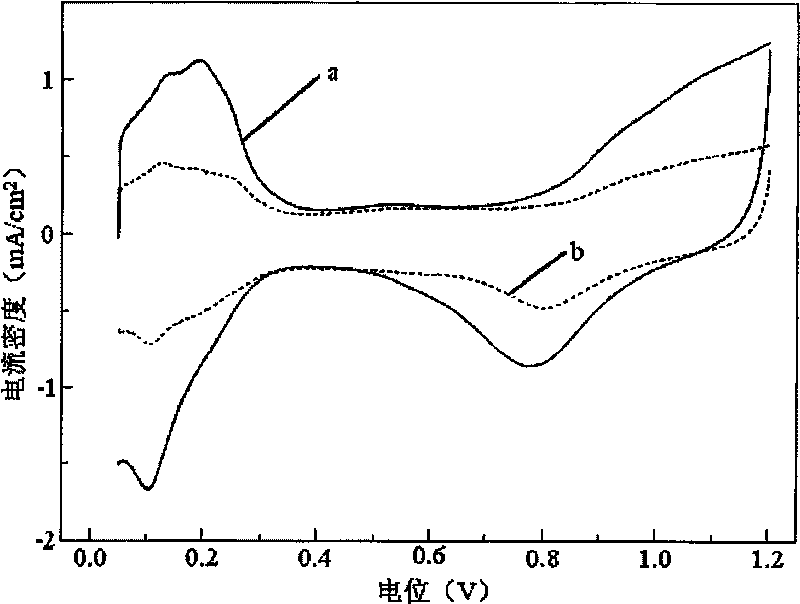

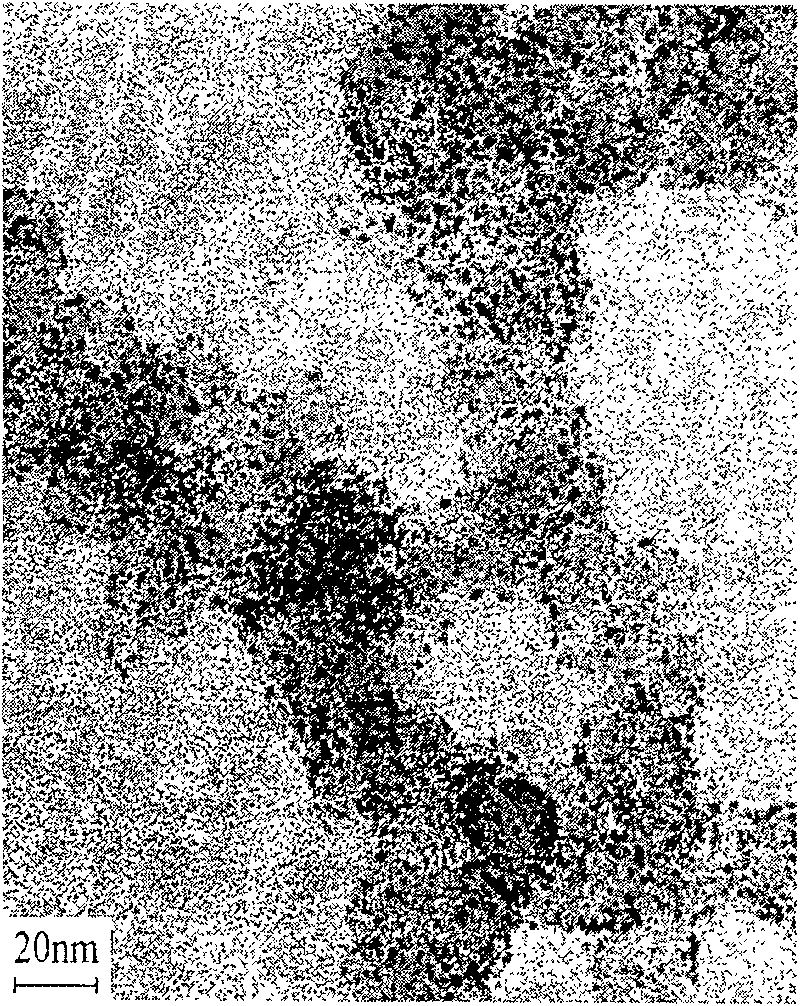

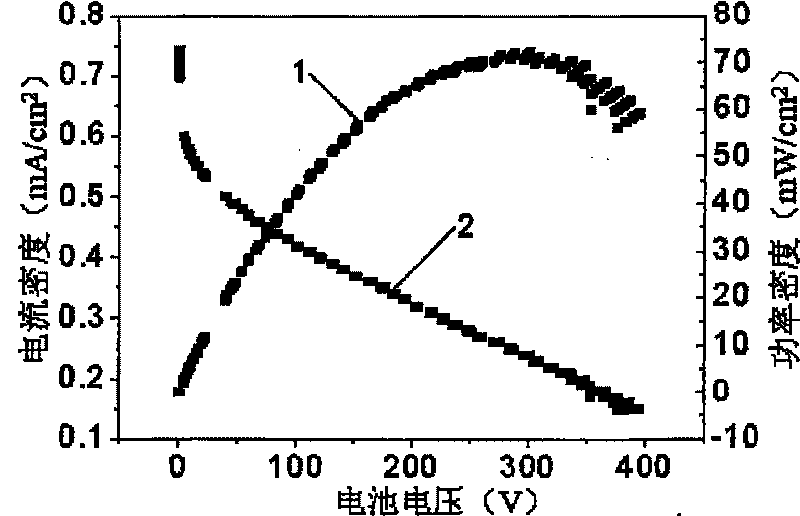

Preparation method of direct methanol fuel cell cathode catalyst

A fuel cell cathode and catalyst technology, applied in battery electrodes, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of uneven particle size dispersion, large Pt catalyst particles, and low utilization rate, and achieve particle size The effect of narrow dispersion, reduced load and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific embodiment one: the preparation method of direct alcohol fuel cell cathode catalyst in this embodiment is carried out according to the following reaction: one, the soluble Pt compound is added in the polyhydric alcohol and disperses evenly, the concentration that obtains Pt ion is 0.0001~15mol / L Adjust the pH value of the mixed solution to 8-14; 2. Use an oil bath to heat, and under the condition of 100-180 ℃ and inert gas protection, reduce the mixed solution for 1-6 hours to obtain a colloidal solution; 3. After acidification The treated carbon carrier and polyol are uniformly mixed at a mass ratio of 1:10 to 100 to obtain a carbon carrier slurry; four, the colloidal solution obtained in step 2 is uniformly dispersed into the carbon carrier slurry in step 3, wherein the carbon carrier and The mass ratio of metal Pt is 5:1~4, and the pH value is adjusted to 1~5, then magnetically stirred for 24 hours, then washed with ultrapure water for 3~5 times, and then dri...

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment differs from Embodiment 1 in that: the concentration of Pt ions in the mixed solution in Step 1 is 0.0005˜10 mol / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 in that the concentration of Pt ions in the mixed solution in Step 1 is 0.005˜5 mol / L. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com