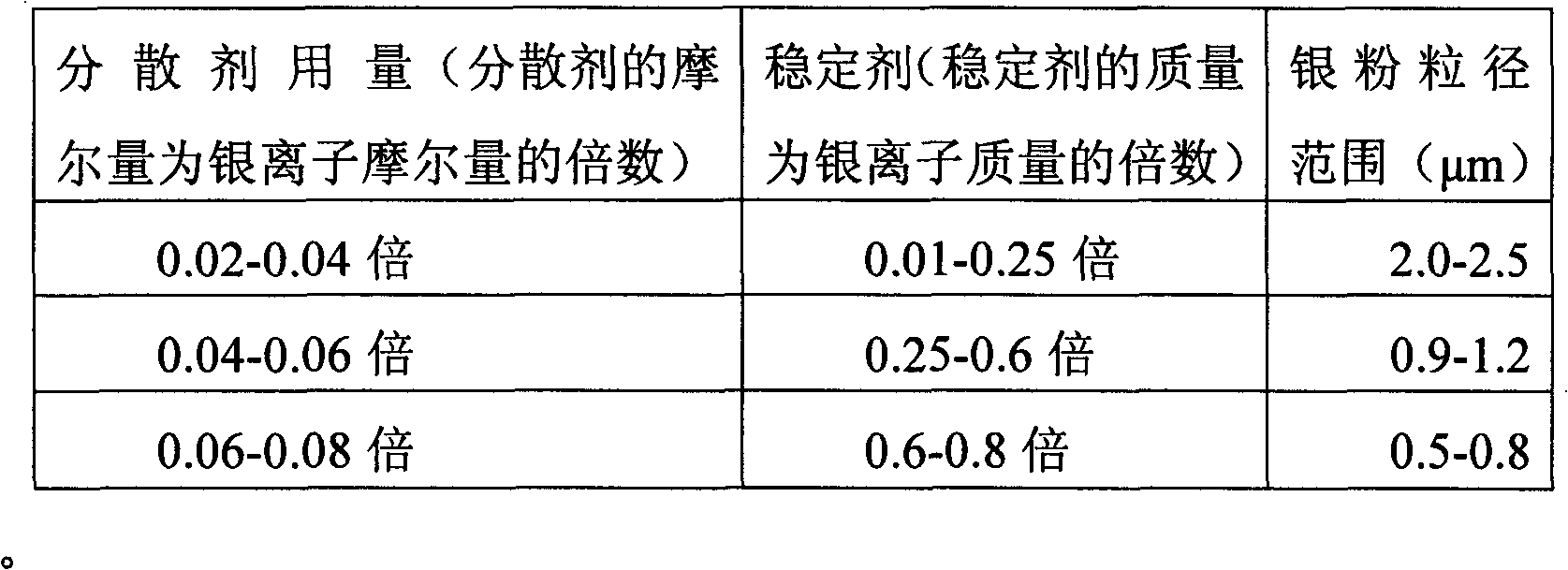

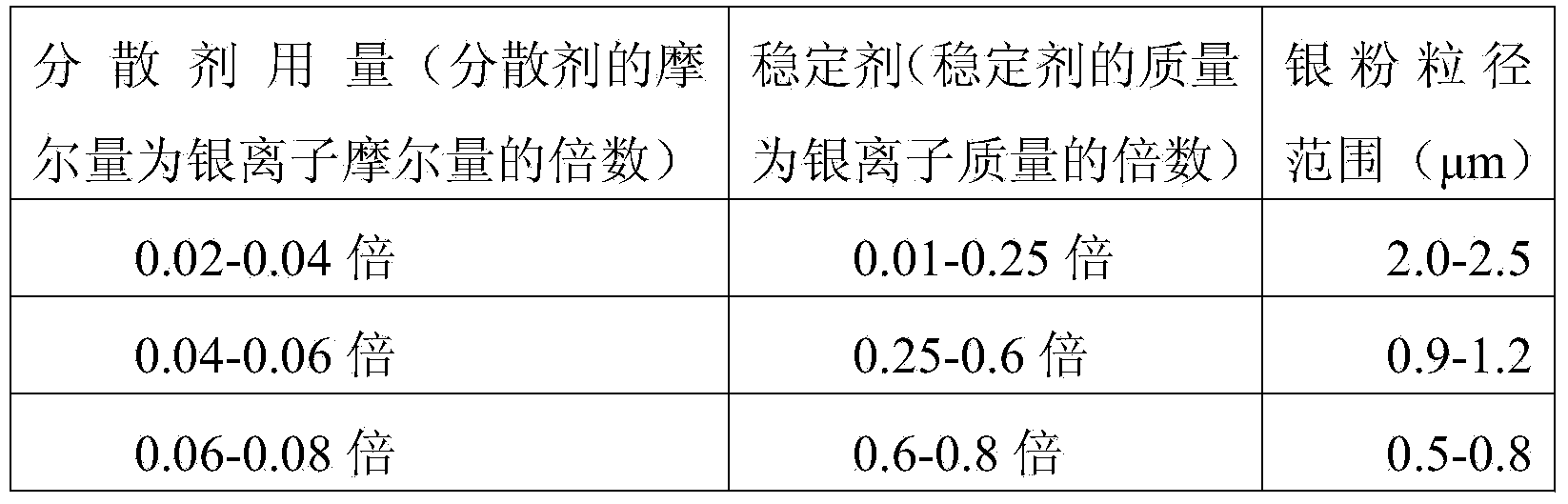

Preparation method of mono-dispersed highly crystalline silver powder with adjustable particle size

A monodisperse, high crystallization technology, applied in the field of electronic components, can solve the problems of unsuitable high resolution and single particle size of silver powder, and achieve the effect of narrow particle size dispersion range, smooth surface and high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] For the reaction vessels, stirring paddles, etc. used, at 85°C, Na 3 PO 4 95g / L, Na 2 CO 3 120g / L, NaOH130g / L, H 2 o 2 25ml / L solution for 15min, then rinse with deionized water.

[0021] Prepare an acidic silver salt solution, in which silver nitrate is 0.30mol / L. Prepare mixed reducing solution. 0.16 mol / L of L-ascorbic acid, 0.009 mol / L of PVP, and 0.60 g / L of potassium nitrate were prepared with deionized water to prepare a mixed reducing solution. Finally, adjust the pH of the mixed reducing solution to 1. While stirring the mixed reducing solution at a low speed, quickly mix the acidic silver salt solution and the mixed reducing solution evenly for reaction, control the reaction temperature at 20° C., and the reaction time is 8 minutes. Post-treatment is performed on the reacted silver powder. After settling for 2 hours, pour out the supernatant reaction solution, and then wash the precipitated silver powder with deionized water until the conductivity ...

Embodiment 2

[0024] For the reaction vessels, stirring paddles, etc. used, at 90°C, Na 3 PO 4 98g / L, Na 2 CO 3 130g / L, NaOH140g / L, H 2 o 2 20ml / L solution for 20min, then rinse with deionized water.

[0025] Prepare an acidic silver salt solution, in which silver nitrate is 0.40mol / L. Prepare mixed reducing solution. 0.22 mol / L of L-ascorbic acid, 0.02 mol / L of oleic acid, and 0.35 g / L of potassium carbonate were prepared into a mixed reducing solution with deionized water. Finally, adjust the pH of the mixed reducing solution to 0.3. While stirring the mixed reducing solution at a low speed, quickly mix the acidic silver salt solution and the mixed reducing solution uniformly for reaction, control the reaction temperature at 25° C., and the reaction time is 6 minutes. Post-treatment is performed on the reacted silver powder. After settling for 3 hours, pour out the supernatant reaction solution, then wash the precipitated silver powder with deionized water until the conductivi...

Embodiment 3

[0028] For the reaction vessels, stirring blades, etc. used, at 80°C, Na 3 PO 4 100g / L, Na 2 CO 3 130g / L, NaOH150g / L, H 2 o 2 25ml / L solution for 15min, then rinse with deionized water.

[0029] Prepare an acidic silver salt solution, in which silver nitrate is 0.35mol / L. Prepare mixed reducing solution. 0.18 mol / L of L-ascorbic acid, 0.025 mol / L of ammonium stearate, and 0.8 g / L of potassium sulfate were prepared with deionized water to prepare a mixed reducing solution. Finally, adjust the pH of the mixed reducing solution to 0.5. While stirring the mixed reducing solution at a low speed, quickly mix the acidic silver salt solution and the mixed reducing solution evenly for reaction, control the reaction temperature at 30° C., and the reaction time for 10 minutes. Post-treatment is performed on the reacted silver powder. After 4 hours of sedimentation, the supernatant reaction solution was poured out, and then the precipitated silver powder was washed with deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com