Method for preparing ultrafine silver powder with uniform particle size

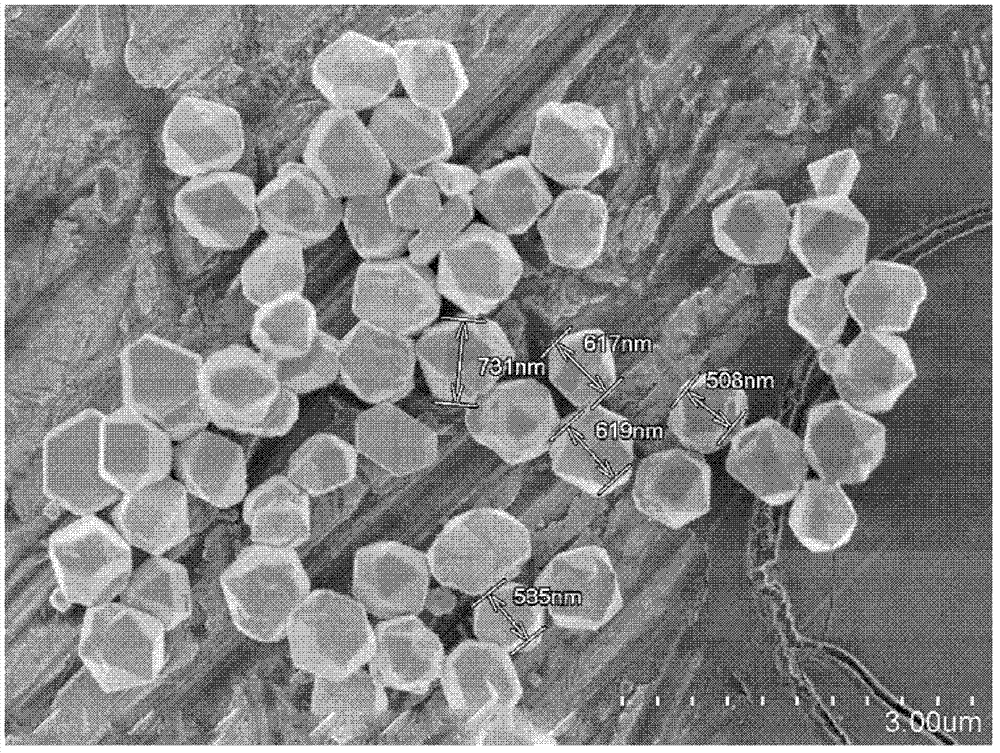

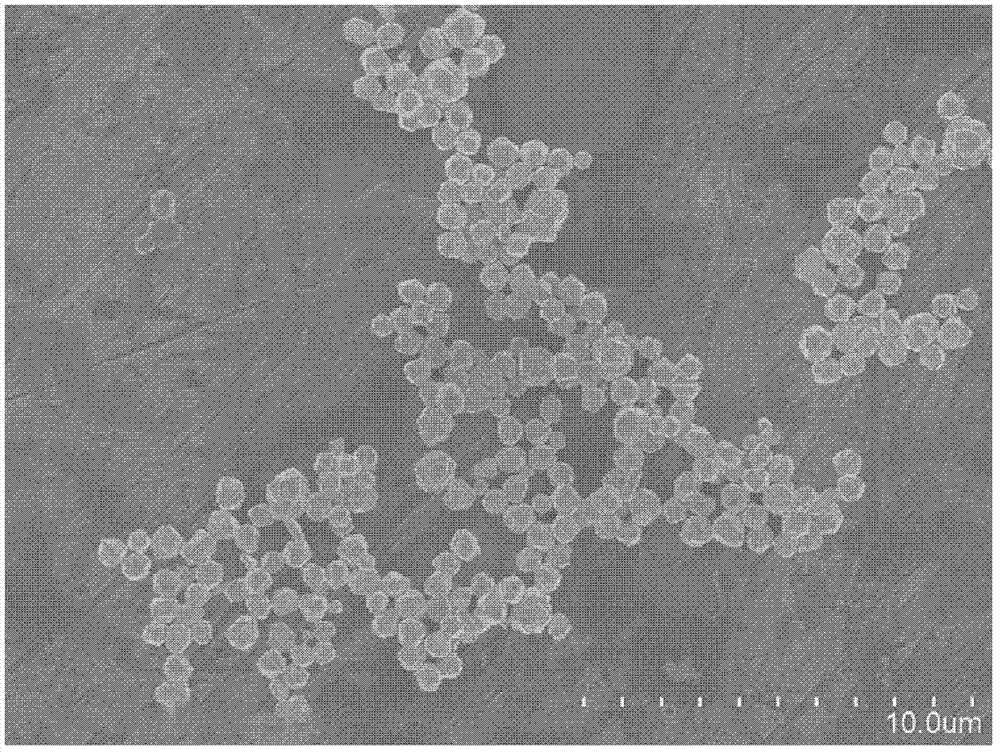

A technology with uniform particle size, applied in the field of preparation of ultra-fine silver powder with uniform particle size, can solve the problems of low process efficiency, difficulty in large-scale production, uneven particle size distribution of silver powder, etc., and achieve high particle sphericity and particle size dispersion range Narrow, smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] All reaction containers and stirring rods used should be boiled in a solution of 150g / L NaOH and 50ml / L H2O2 for 15 minutes at 75°C. Fully hydroxylate the surface of the reactor to avoid silver mirrors during the reaction. The cleaned reactor should be washed with deionized water. Prepare silver ammonia solution, wherein silver nitrate 34g / L, ethylenediamine solution 24.04g / L. Prepare mixed reducing solution, potassium tartrate 26g / L, gum arabic 2g / L, nano-gold colloid 2g / L and deionized water to prepare mixed reducing solution 500mL. Under the condition of a constant temperature water bath, the silver ethylenediamine ammonia solution and the mixed reducing solution were uniformly mixed for reaction, the reaction temperature was controlled at 70° C., and the reaction time was 10 minutes. Transfer the reacted solution to another clean beaker, let it settle for 12 hours, pour off the supernatant, then wash the precipitated silver powder with deionized water until the co...

Embodiment 2

[0022] All reaction containers, glass rods, etc. used should be boiled in a solution of 150g / L NaOH and 50ml / L H2O2 for 10 minutes at 80°C. Fully hydroxylate the surface of the reactor to avoid silver mirrors during the reaction. The cleaned reactor should be washed with deionized water. Prepare silver ethylenediamine ammonia solution, in which silver nitrate is 42.5g / L and ethylenediamine is 30.05g / L. Prepare mixed reducing solution, potassium tartrate 32.5g / L, gum arabic 2.5g / L, nano-gold colloid 2.5g / L and deionized water to prepare 500mL mixed reducing solution. Under the condition of a constant temperature water bath, the silver ammonia solution and the mixed reducing solution were uniformly mixed for reaction, the reaction temperature was controlled at 40° C., and the reaction time was 30 minutes. Transfer the reacted solution to another clean beaker, let it settle for 12 hours, pour off the supernatant reaction solution, then wash the precipitated silver powder with d...

Embodiment 3

[0025] All reaction containers and stirring paddles should be boiled in a solution of 175g / L NaOH and 50ml / L H2O2 for 10 minutes at 82°C. Fully hydroxylate the surface of the reactor to avoid silver mirrors during the reaction. The cleaned reactor should be washed with deionized water. Prepare silver ethylenediamine ammonia solution, in which silver nitrate is 37.4g / L and ethylenediamine is 26.5g / L. Prepare mixed reducing solution. Potassium tartrate 28.6g / L, gum arabic 2.2g / L, nano gold glue 2.2g / L were prepared with deionized water to prepare 500mL mixed reducing solution. In a constant temperature water bath, the silver ammonia solution and the mixed reducing solution are uniformly mixed for reaction, and the reaction temperature is controlled at 35° C. and the reaction time is 60 minutes. Post-treatment is performed on the reacted silver powder. After 12 hours of sedimentation, the supernatant reaction solution was poured out, and then the precipitated silver powder wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com