Purification process for removing sulphur and carbon dioxide in gas by using two-step method

A carbon dioxide, purification process technology, applied in the direction of combustible gas purification, combustible gas purification/renovation, petroleum industry, etc., can solve the problems of complex device process, inconvenient operation and management, large diameter and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

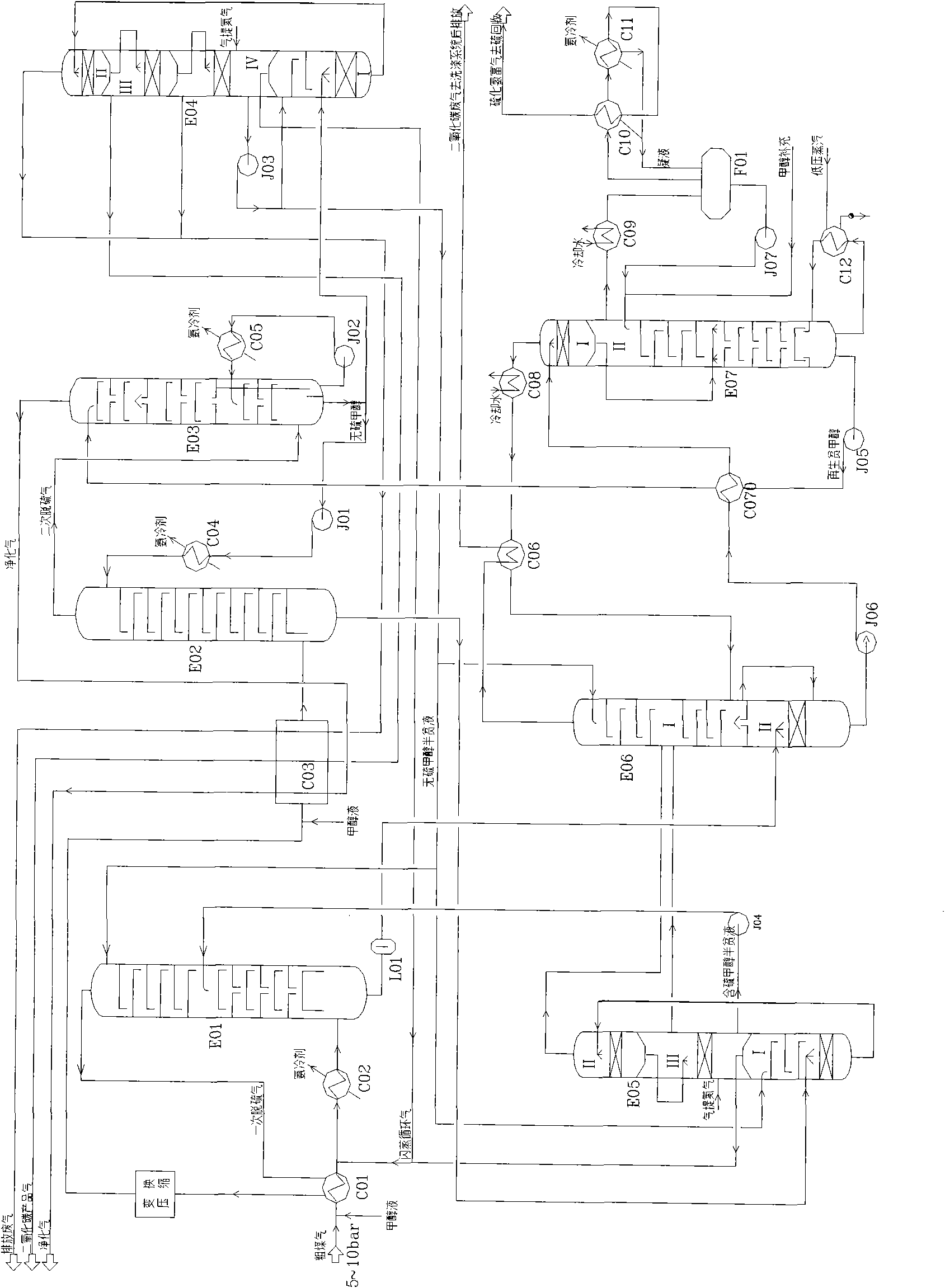

Method used

Image

Examples

Embodiment 1

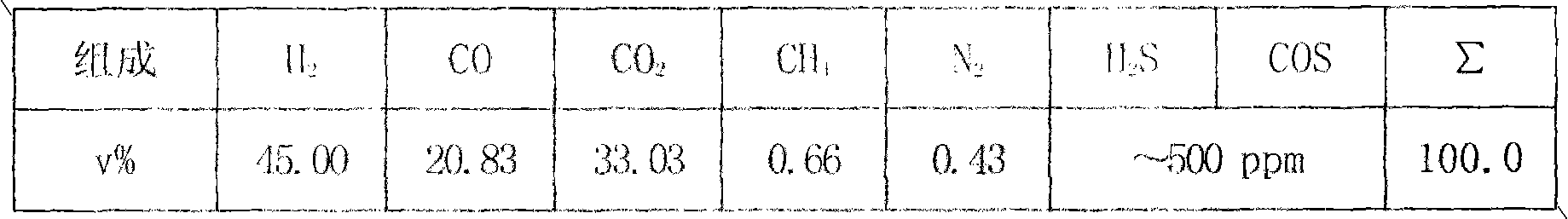

[0070] In this embodiment, the raw gas processed by the process of the present invention is raw gas from coal gasification, and the processing capacity of low-pressure high-sulfur crude gas: 120000Nm 3 / h, temperature: 40°C, pressure: 0.5MPa, the specific gas composition of high-sulfur crude gas is:

[0071] composition

H 2

CO

CO 2

CH 4

N 2

h 2 S

COS

∑

V%

40.16

30.00

27.40

0.70

0.51

1.11

0.12

100.0

[0072] After the low-pressure crude gas desulfurization step described in the process of the present invention, the total sulfur content is reduced to about 500ppm, then sent to the factory compression section to pressurize to about 3.5MPa, and partially converted in the carbon monoxide conversion device to meet the methanol Synthesize the required hydrogen / carbon ratio, and then return the converted gas to the device described in the process of the pr...

Embodiment 2

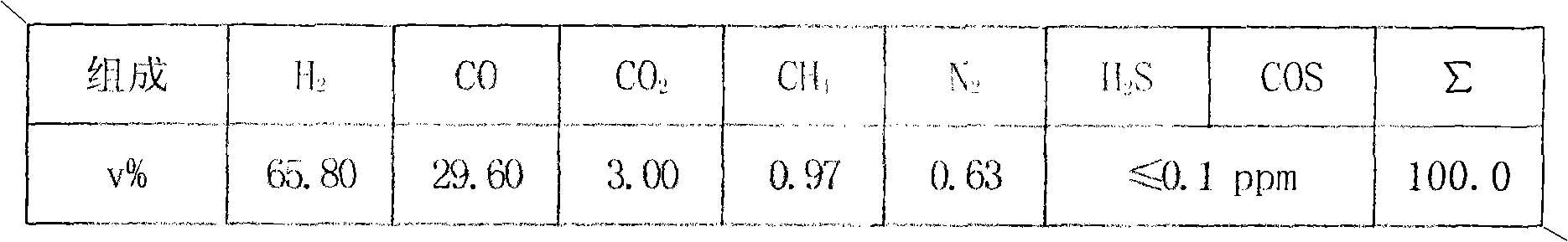

[0110] In this embodiment, the raw gas processed by the process of the present invention is a high-sulfur crude gas from a coal gasification device, and the processing capacity of low-pressure high-sulfur crude gas: 180000Nm 3 / h, temperature: 40°C, pressure: 0.85MPa, the specific gas composition of high-sulfur crude gas is:

[0111] composition

H 2

CO

CO 2

CH 4

N 2

h 2 S

COS

NH 3

∑

V%

41.20

28.60

28.10

0.65

0.50

0.85

0.10

50-80ppm

100.0

[0112] After the low-pressure crude gas desulfurization step described in the process of the present invention, the total sulfur content is reduced to about 500ppm, then sent to the factory compression section to pressurize to 3.7MPa, and partially converted in the carbon monoxide conversion device, and then the gas is converted Return to the device described in the process of the present invention to perform steps such as hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com