Semiconductor failure analysis structure and formation method, method of detecting failure time

A failure analysis and semiconductor technology, applied in the direction of single semiconductor device testing, semiconductor/solid-state device testing/measurement, etc., can solve the problems of small voltage between test pads, difficulty in detecting electromigration, and small resistance value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

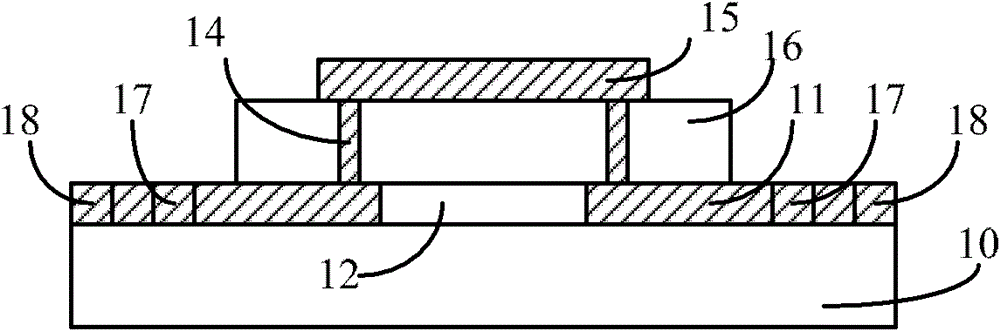

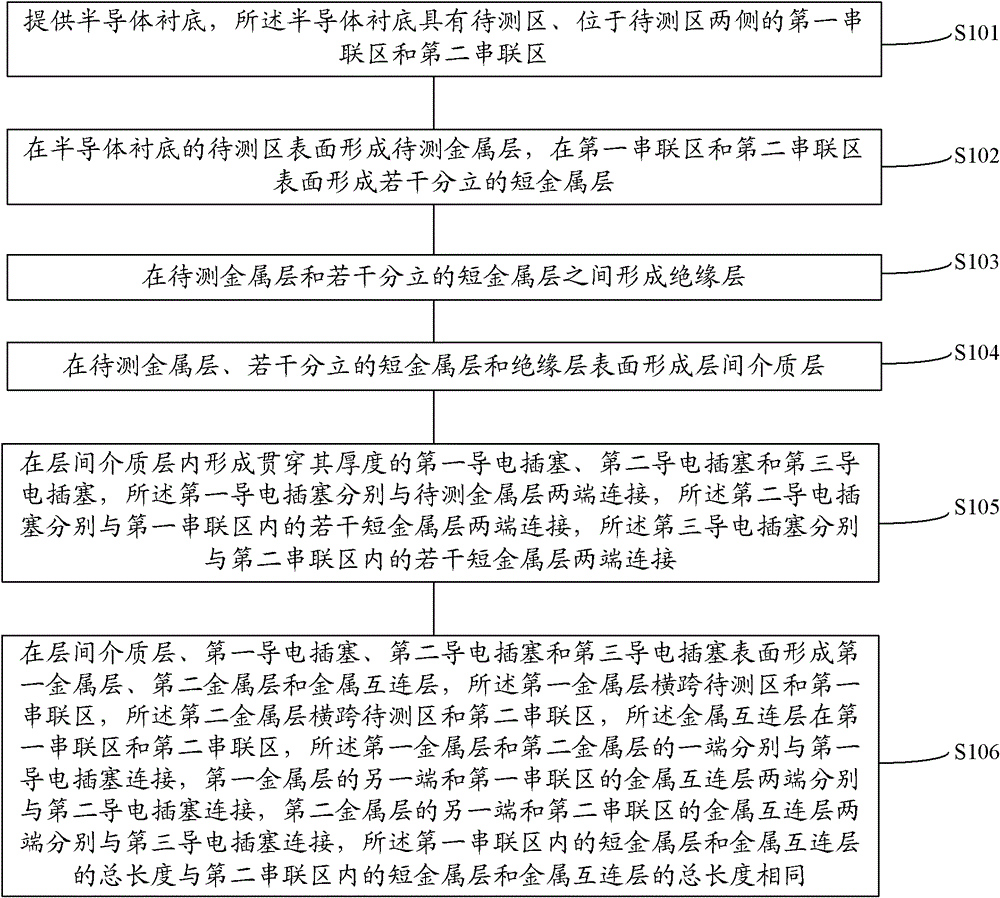

[0094] Please refer to figure 2 , a method for forming a semiconductor failure analysis structure, comprising the following steps:

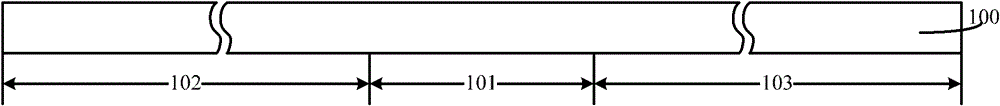

[0095] Step S101, providing a semiconductor substrate, the semiconductor substrate has a region to be tested, a first series region and a second series region located on both sides of the region to be tested;

[0096] Step S102, forming a metal layer to be tested on the surface of the semiconductor substrate to be tested, and forming several discrete short metal layers on the surface of the first serial region and the second serial region;

[0097] Step S103, forming an insulating layer between the metal layer to be tested and several discrete short metal layers;

[0098] Step S104, forming an interlayer dielectric layer on the surface of the metal layer to be tested, several discrete short metal layers, and the insulating layer;

[0099] Step S105, forming a first conductive plug, a second conductive plug, and a third conductive plug through ...

specific Embodiment 2

[0125] Please refer to Figure 7 , a method for forming a semiconductor failure analysis structure, comprising the following steps:

[0126] Step S201, providing a semiconductor substrate, the semiconductor substrate has a region to be tested, a first series region and a second series region located on both sides of the region to be tested;

[0127] Step S202, forming a first metal layer, a second metal layer and a metal interconnection layer on the surface of the semiconductor substrate, the first metal layer straddles the region to be tested and the first series region, and the second metal layer straddles the region to be tested The measurement area and the second series area, the metal interconnection layer is in the first series area and the second series area;

[0128] Step S203, forming an insulating layer between the first metal layer, the second metal layer and the metal interconnection layer;

[0129] Step S204, forming an interlayer dielectric layer on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com