Central transmission thickener driving device

A driving device and central transmission technology, applied in the field of thickeners, can solve the problems of unstable and unsmooth rake lifting, high frequency of use and maintenance, and high failure rate of operation, reducing the frequency of use and maintenance, improving operation stability, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

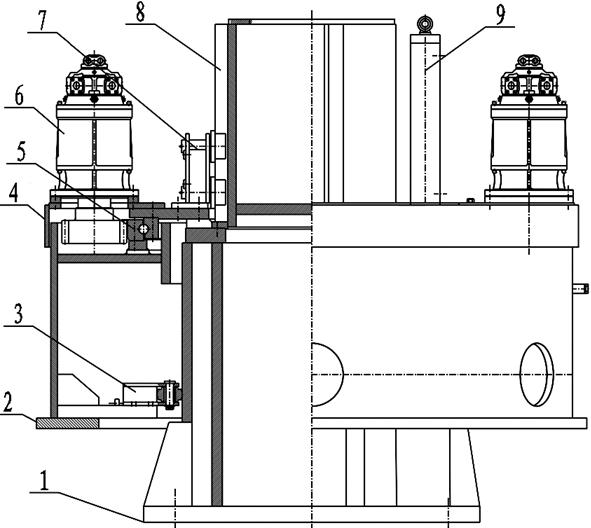

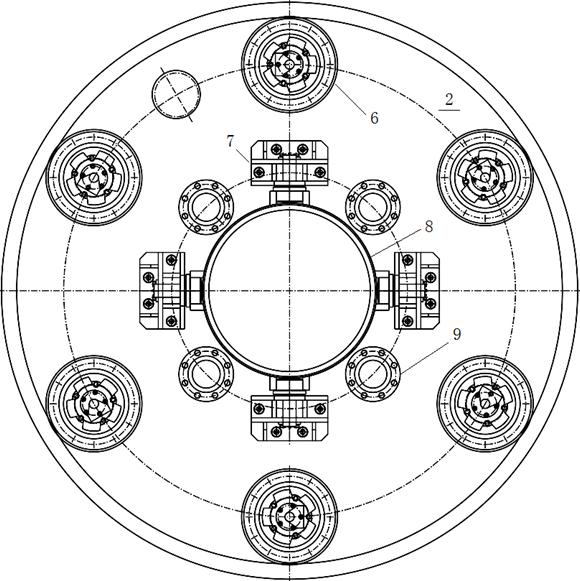

[0020] Such as figure 1 , 2 As shown, a driving device for a central transmission concentrator includes a fixed seat 1, a rotating frame 2, a slewing bearing 5, a low-speed high-torque reducer 6, a guide wheel set 7, a guide tube shaft 8, a rake cylinder 9, and a guide tube shaft 8 is fixed on the upper part of the fixed seat 1 by bolts; the rotating frame 2 is installed on the fixed seat 1 through the slewing bearing 5, and the rotating frame 2 is sleeved on the guide tube shaft 8, and the low-speed high-torque reducer 6 is installed on the rotating frame 2. Connect the slewing bearing 5 and drive the slewing bearing 5 to rotate, and at least two low-speed high-torque reducers 6 are arranged symmetrically; In the guide groove, the guide wheels of the guide wheel set 7 are located in the guide groove, and at least two groups of the guide wheel set 7 are arranged symmetrically.

[0021] The roller is used to replace the previous feather key, so that the sliding friction is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com