Acid leaching equipment for high-silica glass fiber

A high-silica glass fiber and glass fiber technology, which is applied to the equipment for acid leaching treatment of high-silica glass fiber and the equipment field of acid leaching treatment, can solve the problem that high-silica glass fiber cotton products cannot meet the requirements and cannot be used for glass fiber. Cotton acid leaching production and other problems, to achieve the effect of improving service life, reducing production costs and saving electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

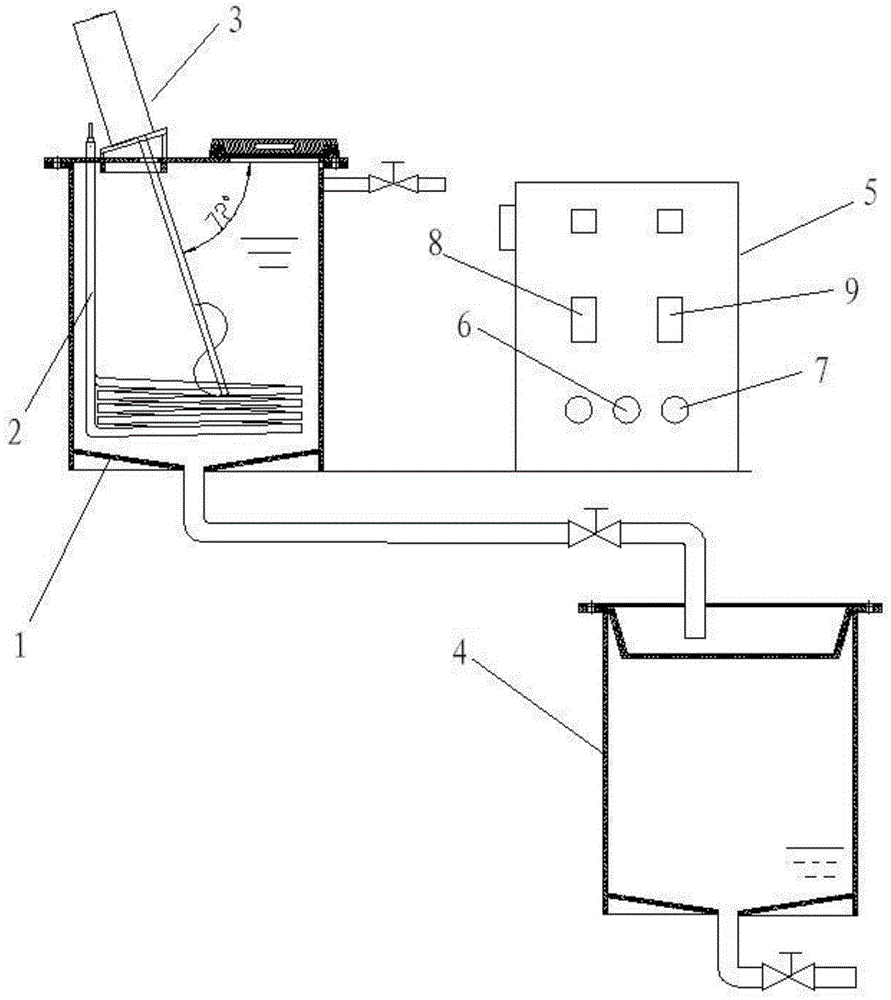

Embodiment 1

[0039] The equipment for acid leaching treatment of high silica glass fiber in the present embodiment includes acid reaction tank 1, heater 2, stirrer 3, filter tank 4 and control part 5; heater 2 and stirring device 3 are all arranged on acid In the reaction barrel 1, the bottom of the acid reaction barrel 1 is connected to the top of the filter barrel 4 through the acid discharge pipe, the acid reaction barrel 1 is located above the filter barrel 4 and there is a difference in liquid level between the two; the agitator 3 is installed obliquely on the acid The inclination angle of the stirring shaft of the agitator in the reaction barrel relative to the horizontal plane is preferably 72°. The control part 5 includes a control cabinet, a controller arranged in the control cabinet, a stirring start-stop button 6 and a heating start-stop button 7 arranged on the control cabinet, a temperature control meter 8 arranged on the control cabinet, and a The stirring governor 9 and the ...

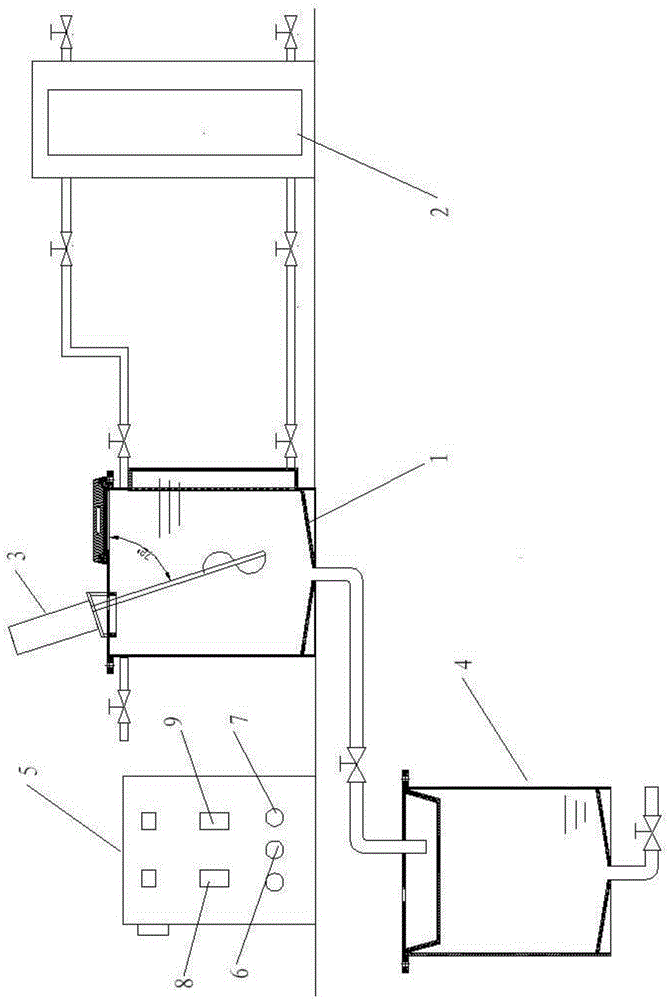

Embodiment 2

[0050] The equipment for acid leaching treatment of high silica glass fiber in this embodiment includes an acid reaction tank 1, a heater 2, an agitator 3, a filter tank 4 and a control component 5; the agitator 3 is obliquely arranged in the acid reaction tank 1 And the inclination angle of the stirring shaft of the agitator 3 relative to the horizontal plane is 72 °, the bottom of the acid reaction tank 1 is connected to the top of the filter tank 4 through the acid discharge pipe, the acid reaction tank 1 is located above the filter tank 4 and there is an The height difference of the liquid level; the heater 2 is arranged outside the acid reaction barrel and connected to the acid reaction barrel 1 through a pipeline. The heater 2 in this embodiment is a heat exchanger. The control part 5 includes a control cabinet, a controller arranged in the control cabinet, a stirring start-stop button 6 and a heating start-stop button 7 arranged on the control cabinet, a temperature con...

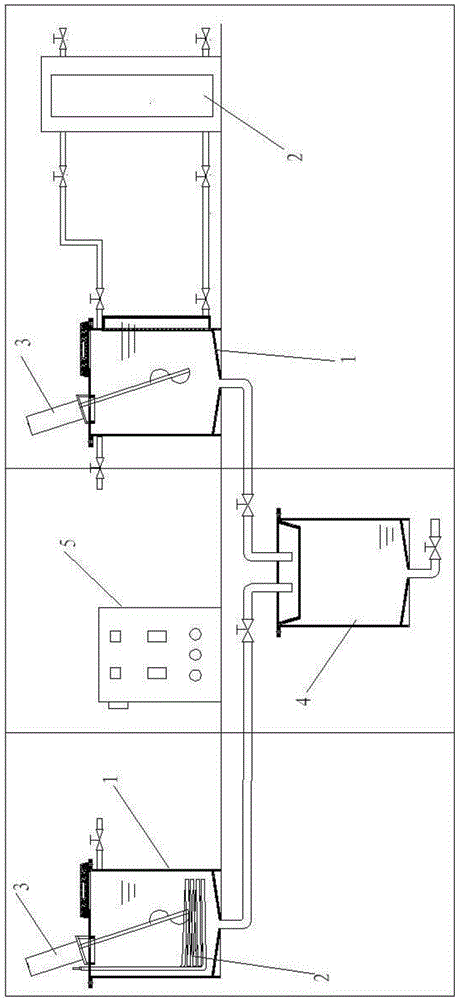

Embodiment 3

[0060] This embodiment is that the high-silica glass fiber acid leaching treatment equipment is the combination of the equipment in embodiment 1 and embodiment 2, and the structure is, the high-silica glass fiber acid leaching treatment equipment in embodiment 1 The acid leaching treatment equipment with a built-in heater for the first stage acid reaction barrel, the specific structure of this equipment is the same as that of the equipment in Example 1. The equipment for the acid leaching treatment of high silica glass fiber in Example 2 is the acid leaching treatment equipment with an external heater in the acid reaction barrel, and the specific structure of this equipment is the same as that of the equipment in Example 2. In this embodiment, the acid leaching treatment equipment with a built-in heater in the first stage of acid reaction barrel and the acid leaching treatment equipment with an external heater in the second stage of acid reaction barrel have the bottoms of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com