Flexible intelligent control method and system for precision shell casting robot

An intelligent control system and precision casting technology, which is applied in the field of precision casting and shell making, can solve problems such as little impact on cost, error-proneness, and insufficient robot application technology, and achieve the effect of reducing operating skill requirements and achieving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

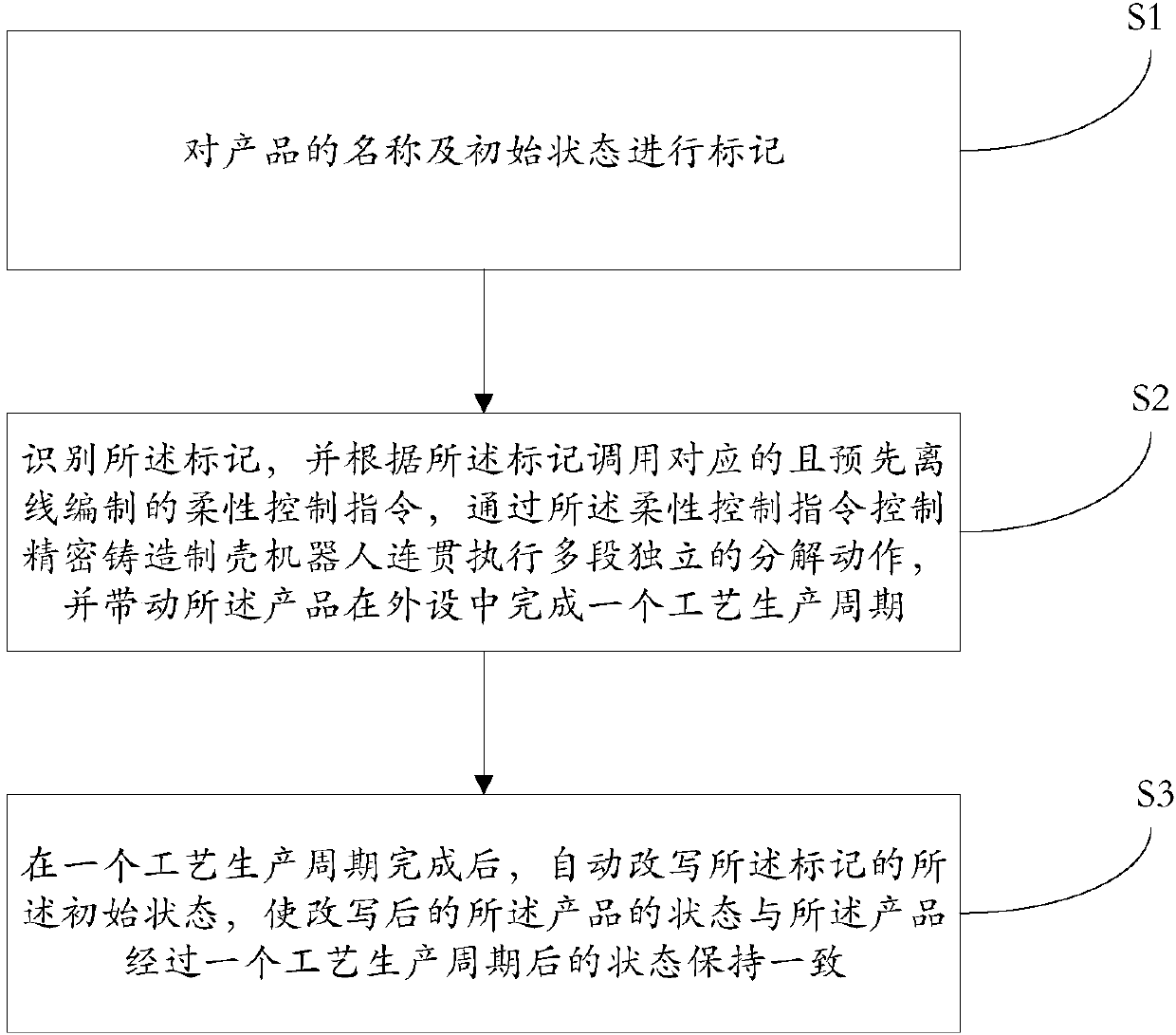

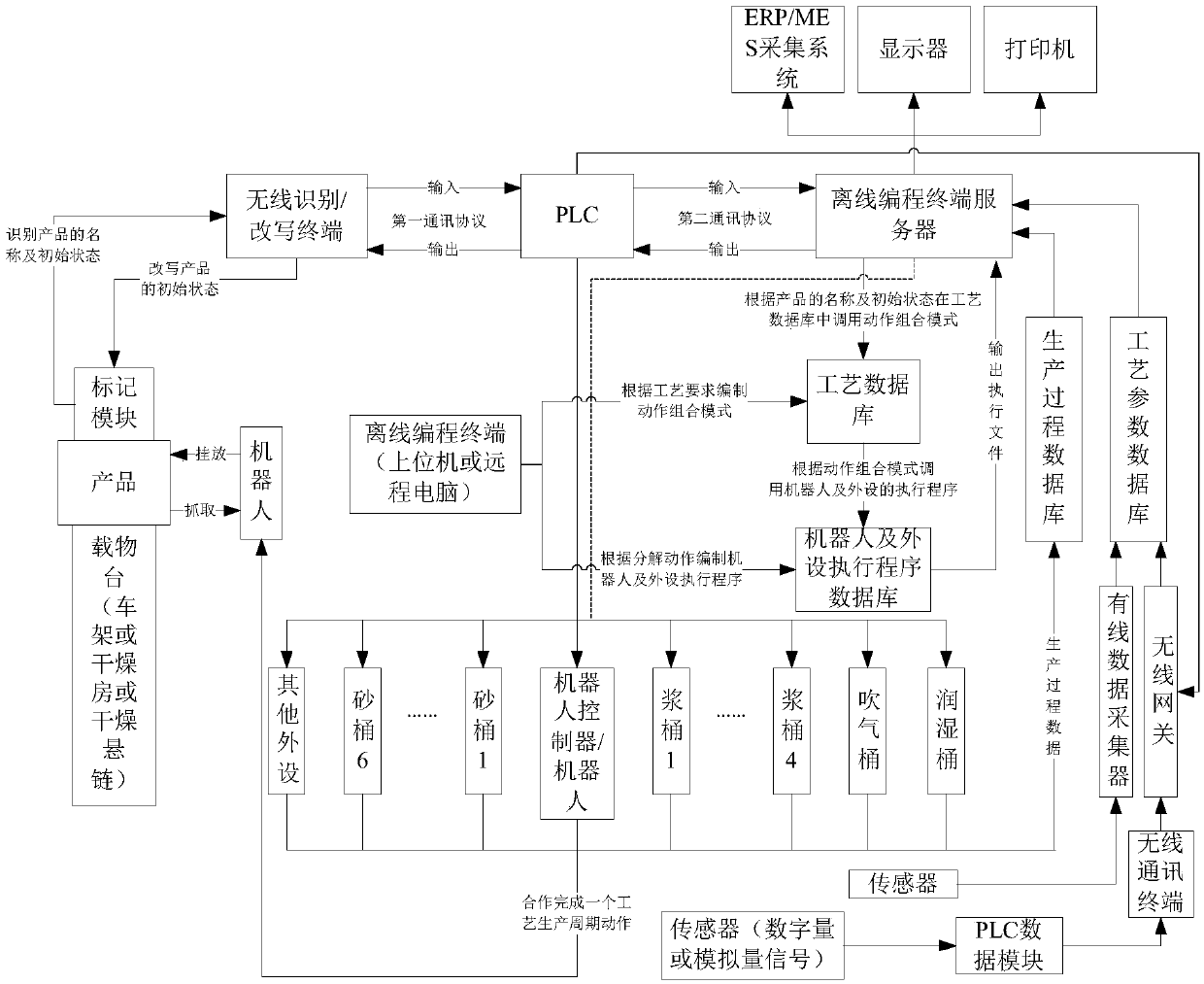

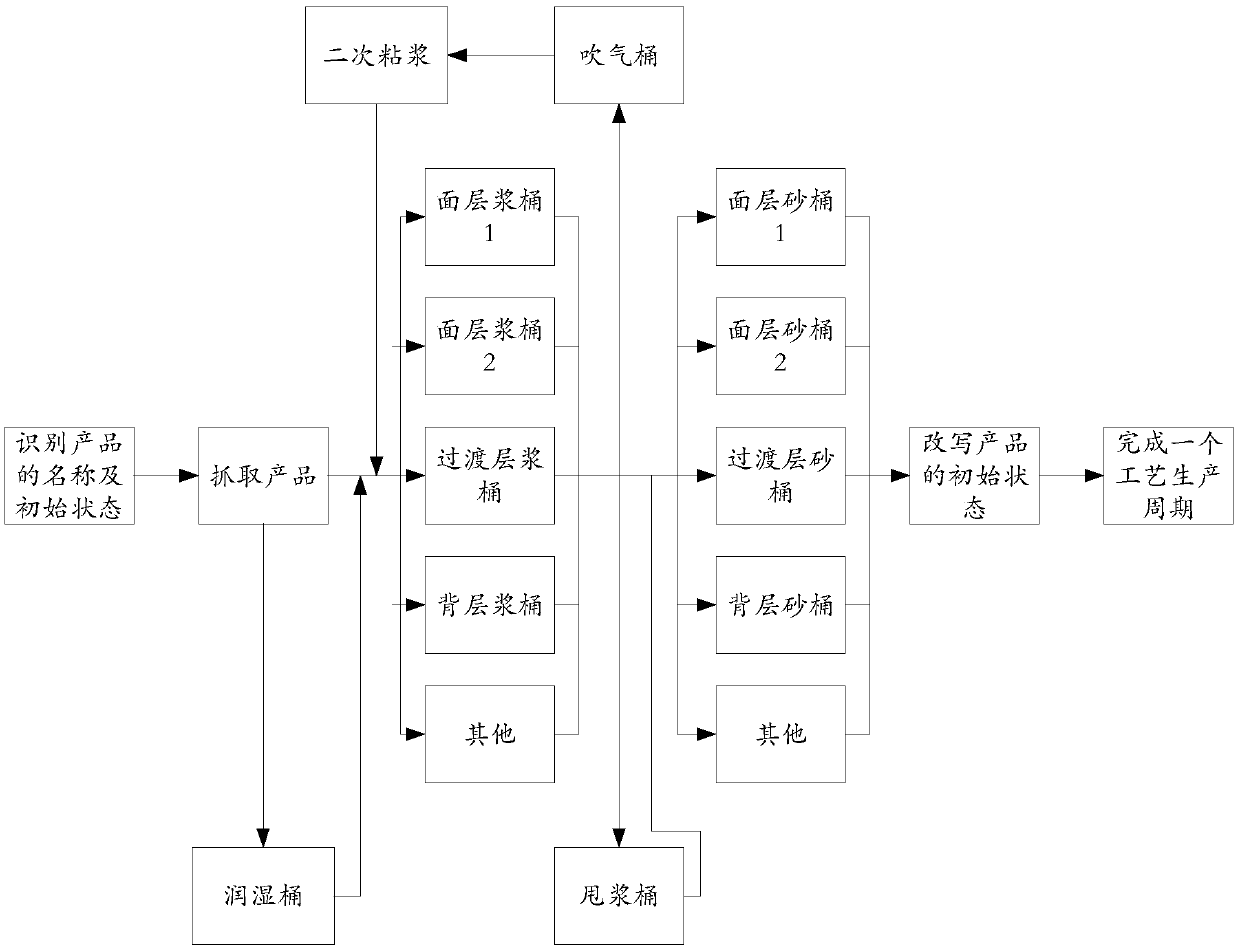

[0060] Such as figure 1 As shown, a flexible intelligent control method for an investment casting shell-making robot comprises the following steps,

[0061] S1, mark the name and initial state of the product;

[0062] S2. Identify the mark, and call the corresponding pre-offline flexible control command according to the mark, and control the precision casting shell-making robot to perform multiple independent decomposition actions coherently through the flexible control command, and drive the product in the peripheral Complete a process production cycle;

[0063] S3. After a process production cycle is completed, automatically rewrite the initial state of the mark, so that the rewritten state of the product is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com