Auxiliary gas control system for double-fluid ejector

A technology of auxiliary gas and control system, applied in the direction of liquid injection device, injection device, etc., can solve the problems of nozzle tailing, wire drawing, inability to realize precise distribution of glue liquid, etc., and achieve the effect of convenient operation and easy maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

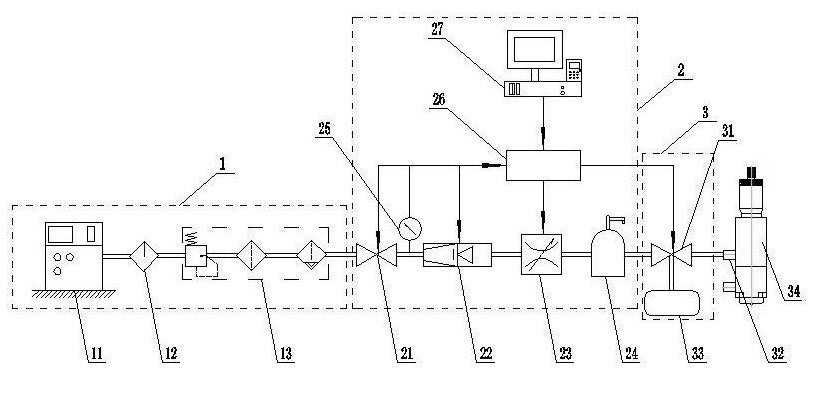

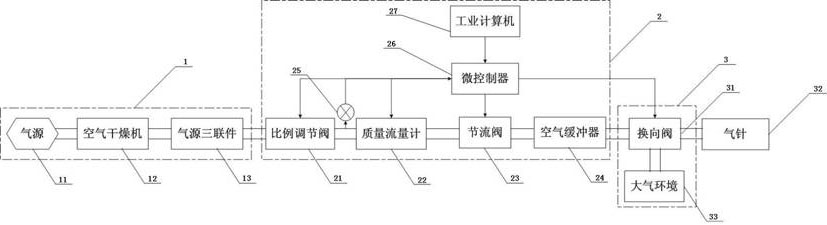

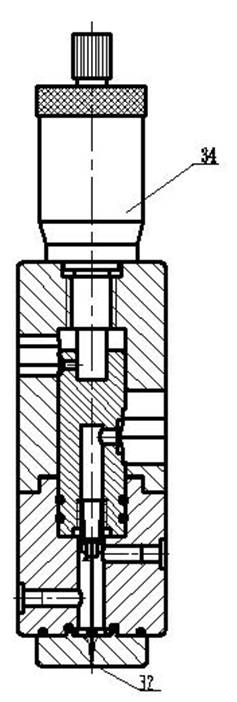

[0026] refer to figure 1 , figure 2 and image 3 , an auxiliary gas control system for a dual-fluid injector, including a gas source device (1), a gas pressure-flow adjustment unit (2), a gas reversing unit (3) and a dual-fluid injector (34), The gas source device (1), gas pressure-flow adjustment unit (2), gas reversing unit (3) and dual-fluid injector (34) are sequentially connected through a gas pipe, and the outlet of the gas reversing unit (3) is connected through a gas pipe The gas needle (32) of the dual-fluid injector (34) realizes the gas supply of the dual-fluid injector (34).

Embodiment 2

[0028] refer to figure 1 and 2 , this embodiment is basically the same as Embodiment 1, the special feature is that the gas source device (1) provides a pure and dry gas source for the system, ensuring the existence of the working medium - gas; the gas source device ( 1) The structure is: a compressed air source (11) is sequentially connected to an air dryer (12) and an air source triple unit (13) through an air pipe, and the air source triple unit (13) is composed of a filter, a lubricator And pressure reducing valve consists of three parts.

Embodiment 3

[0030] refer to figure 1 and 2 , this embodiment is basically the same as Embodiment 1, in particular that the gas pressure-flow adjustment unit (2) provides the downstream equipment with the required flow and pressure of compressed gas to meet the requirements of the experimental process parameters; the gas pressure - The structure of the flow regulating unit (2) is: a proportional regulating valve (21) is sequentially connected to a mass flow meter (22) through the gas pipe, wherein the proportional regulating valve (21), the mass flow meter (22) and the throttle valve (23 ) all have signal ports, and are connected with the signal ports of the microcontroller (26), the microcontroller (26) is connected with the industrial computer (27), and the parameters are set through the industrial computer (27), and the proportional regulating valve ( The outlet of 21) is provided with a pressure sensor (25), and its signal port is connected with the microcontroller (26).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com