Electroplating additive for diamond grinding tool

An electroplating additive and diamond technology, which is applied in the field of electroplating additives, can solve the problems of poor positioning ability of the plating solution, affecting diamond cutting and service life, etc., and achieve fast and perfect electroplating, enhanced grinding force, and increased exposure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

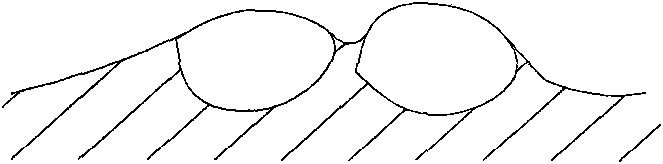

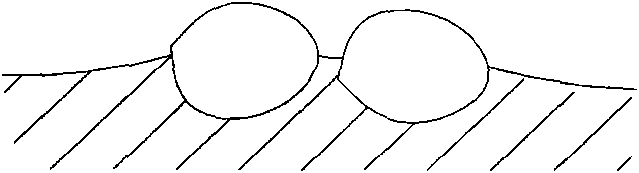

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0020] The diamond abrasive tool electroplating additive provided by the present embodiment comprises three groups of mixtures:

[0021] Mixture A includes pyridine inner salt, glycol substituted ether, pentyne carbonyl ether and unsaturated alkyl pyridine inner salt,

[0022] Mixture B includes unsaturated carbonylpyridine inner salt, quaternized carboxylic acid inner salt, sodium alkynyl sulfonate, phosphorous sulphonyl benzimide, aromatic diethylamine sulfonic acid polycondensate,

[0023] Mixture C is polyoxyethylene phenol sodium sulfate solution.

[0024] In this embodiment, the use concentration of mixture A is 0.8-3.5ml / L, the use concentration of mixture B is 6-30ml / L, and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com