Magnesium alloy surface SiC+Al pile up welding method

A magnesium alloy and workpiece surface technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of insignificant increase in hardness and failure to meet the requirements, and achieve easy control of welding process parameters and comprehensive stacking The effect of welding remelting and reasonable process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

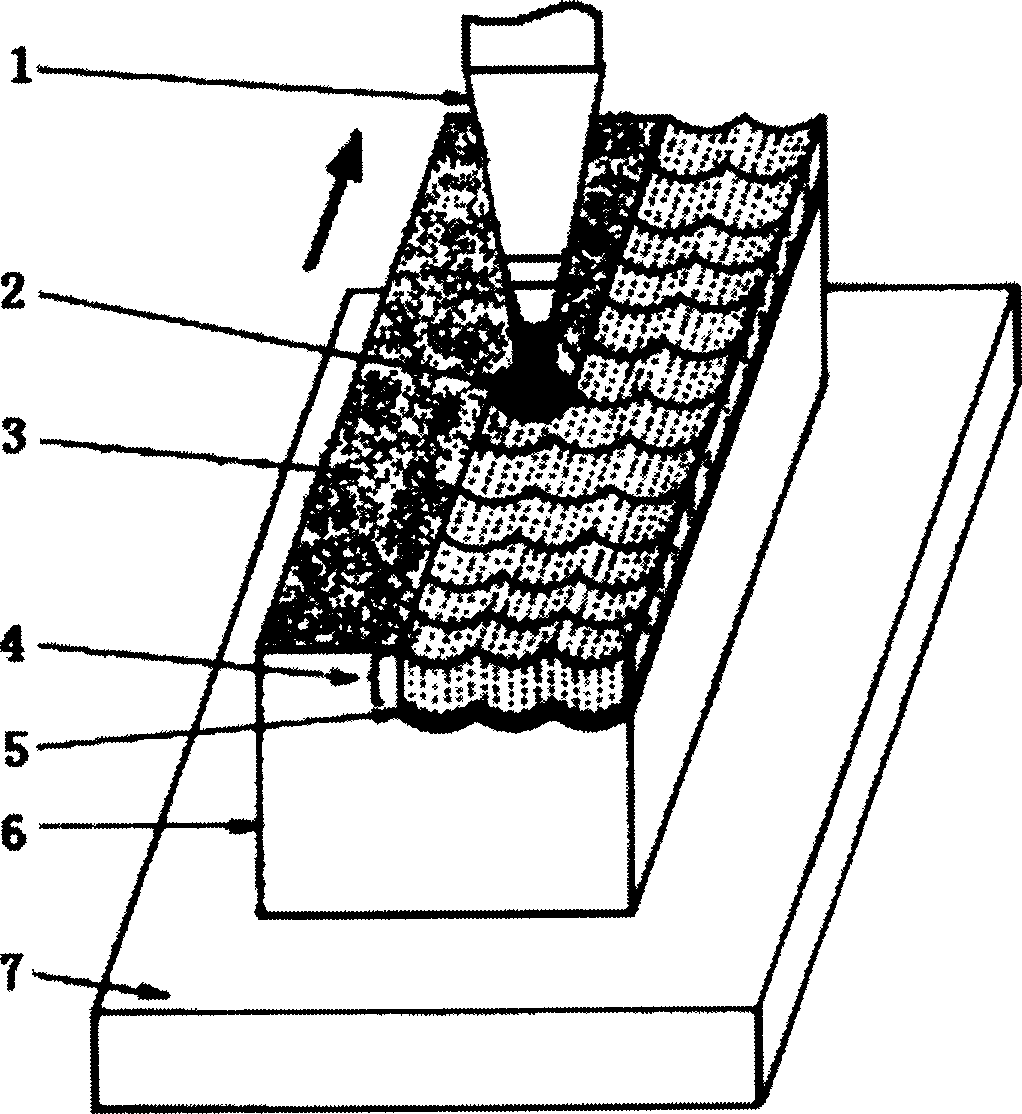

Image

Examples

Embodiment 1

[0019] A deformed magnesium alloy AZ31B plate with a thickness of 3.6mm is selected (the sample size is 200×100×3.6mm), the particle size of aluminum powder and silicon carbide powder are both 7 μm, and the mixing volume ratio of silicon carbide powder and aluminum powder is: Silicon carbide powder: aluminum powder = 1:5, and the binder used is polyvinyl butyral. Fully mix silicon carbide powder and aluminum powder, add binder and stir evenly, apply the coating material evenly on the surface of the clean magnesium alloy workpiece that has been cleaned of impurities such as oxide film, and the coating thickness is 0.1mm. The welding current of argon tungsten arc welding is 60A (AC), the diameter of the tungsten electrode of the welding torch is F1.6mm, the welding speed is 5mm / s, the argon gas flow rate of the welding torch is 5L / min, the angle of the welding torch (between the welding torch and the plane where the welding seam is located The included angle) is 50°, and argon i...

Embodiment 2

[0021]A cast magnesium alloy AZ91B plate with a thickness of 8mm is selected (the sample size is 200×100×8mm), the particle size of aluminum powder and silicon carbide powder are both 50 μm, and the mixing volume ratio of silicon carbide powder and aluminum powder is: silicon carbide powder : Aluminum powder = 1: 3.5, the binder used is polyvinyl butyral. Fully mix silicon carbide powder and aluminum powder, add binder and stir evenly, apply the coating material evenly on the surface of the clean magnesium alloy workpiece that has been cleaned of impurities such as oxide film, and the coating thickness is 0.5mm. The welding current of the argon tungsten arc welding is 130A (AC), the diameter of the tungsten electrode of the welding torch is F2. The included angle) is 70°, and argon is used as the shielding gas. The surface analysis of the magnesium alloy after surfacing-remelting treatment shows that the thickness of the fusion layer is 1.3mm, SiC particles are evenly embedde...

Embodiment 3

[0023] The casting magnesium alloy AM60 plate with a thickness of 10mm is selected (the sample size is 200×100×10mm), the particle size of aluminum powder and silicon carbide powder are both 100 μm, and the mixing volume ratio of silicon carbide powder and aluminum powder is: silicon carbide powder : Aluminum powder = 1: 2, the binder used is polyvinyl butyral. Fully mix silicon carbide powder and aluminum powder, add binder and stir evenly, apply the coating material evenly on the surface of the clean magnesium alloy workpiece that has been cleaned of impurities such as oxide film, and the coating thickness is 1.0mm. The welding current of argon tungsten arc welding is 200A (AC), the diameter of the tungsten electrode of the welding torch is F2.2mm, the welding speed is 15mm / s, the argon flow rate of the welding torch is 15L / min, the angle of the welding torch (between the welding torch and the plane where the welding seam is located The included angle) is 90°, and argon is u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com