Direct-driving three-freedom serial-parallel mixed precision positioning mechanism

A precision positioning and degree of freedom technology, applied in the direction of manipulators, instruments, metal processing, etc., can solve the problems of influence, difficulty in meeting the requirements of precision and work efficiency in the microelectronics industry, and long mechanical establishment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

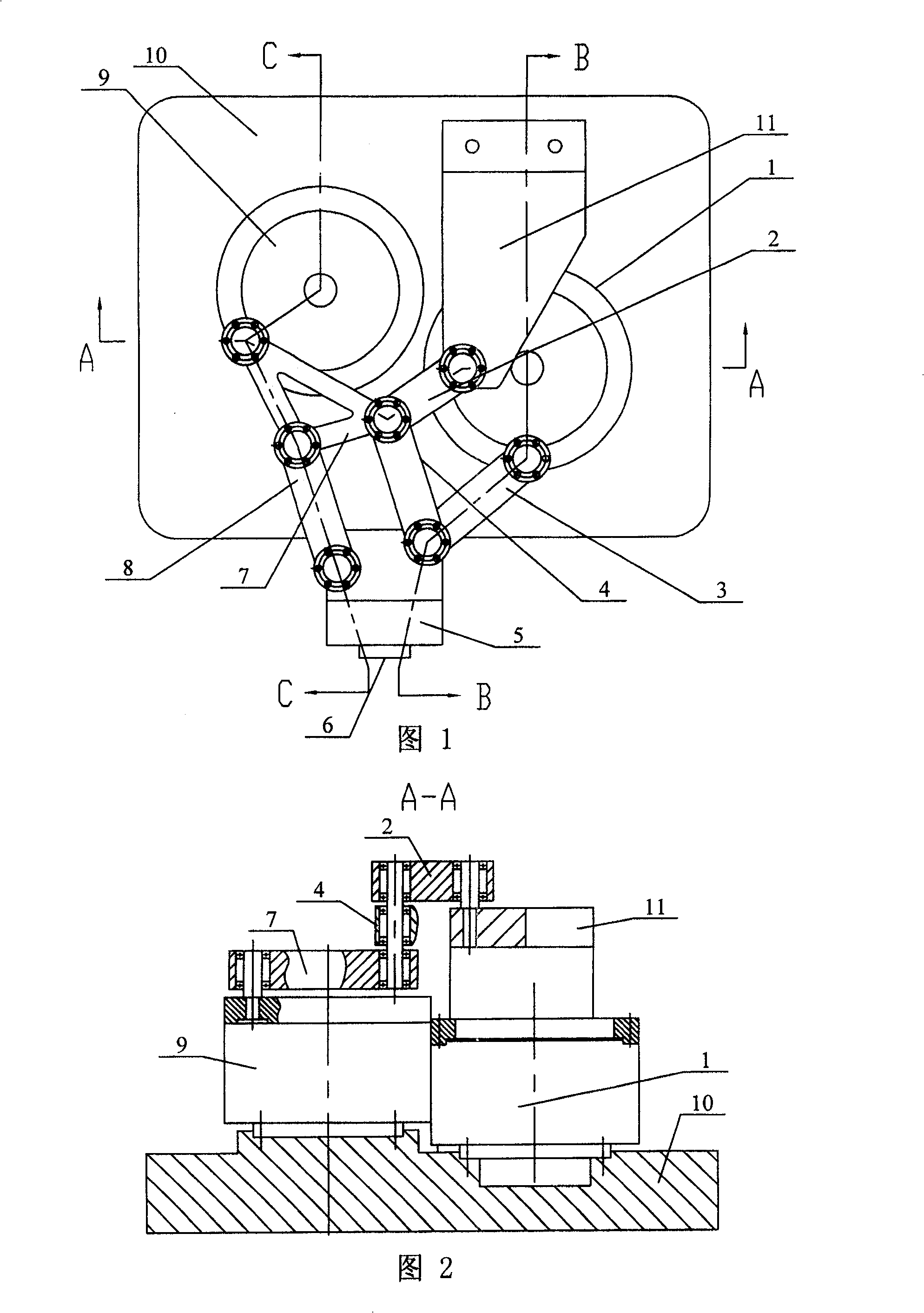

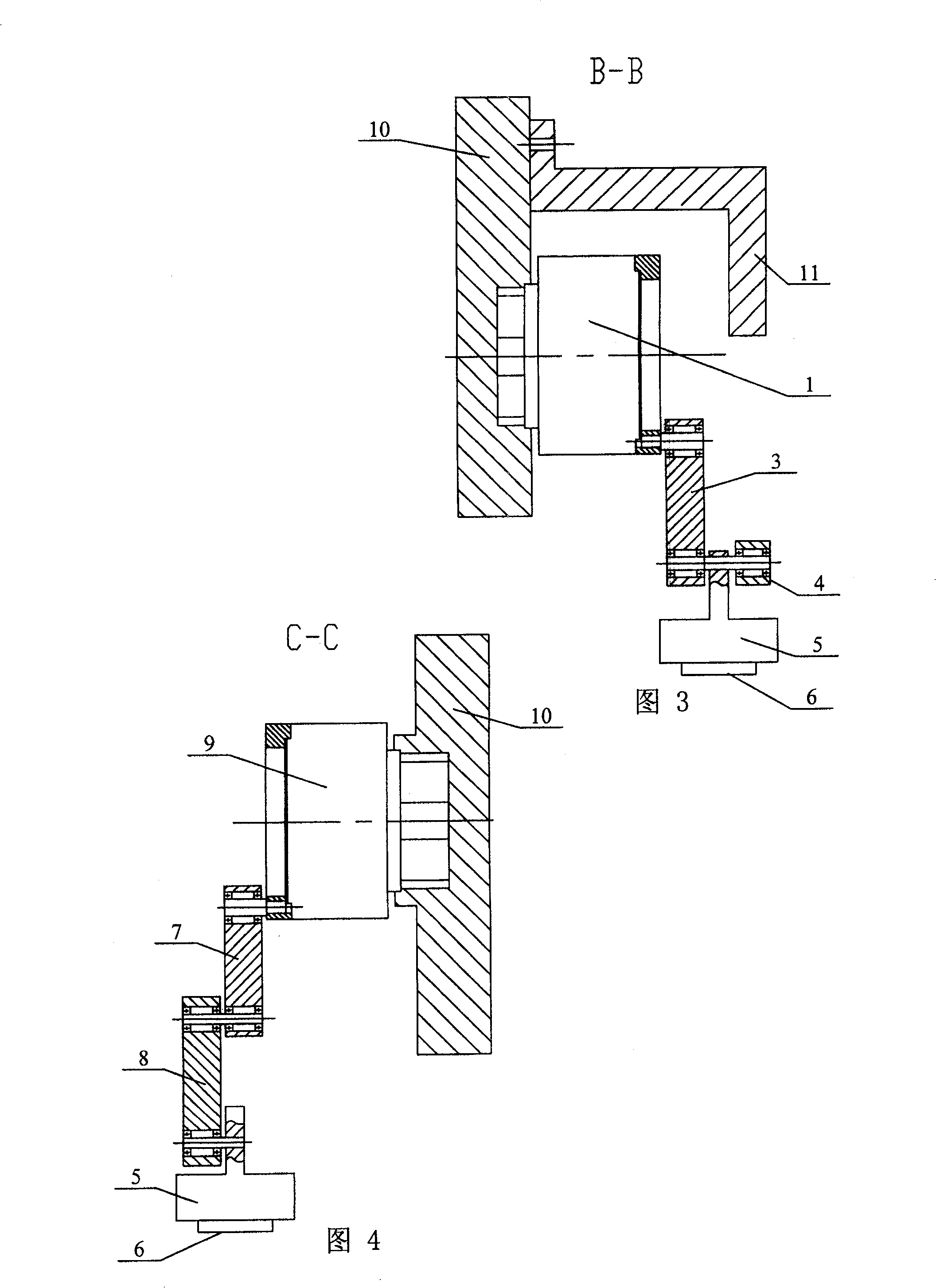

[0005] (see Fig. 1-Fig. 4) present embodiment is made up of No. 1 motor 1, No. 1 connecting rod 2, No. 2 connecting rod 3, No. 3 connecting rod 4, output module 5, linear motion module 6, No. 4 connecting rod 7, The fifth connecting rod 8, the second motor 9, the machine base 10, and the bent plate 11 are composed; the bent plate 11 is fixed on one side of the machine base 10, and the bases of the first motor 1 and the second motor 9 are respectively fixed on the machine base 10 Above, one end of the No. 1 connecting rod 2 is hinged to the curved plate 11, the other end of the No. 1 connecting rod 2 is hinged to one end of the No. 3 connecting rod 4 and No. 4 connecting rod 7, and one end of the No. The output end of No. 1 is hinged, the other end of No. 3 connecting rod 4, the other end of No. 2 connecting rod 3, and the output module 5 are hinged sequentially from top to bottom, and the other end of No. 4 connecting rod 7 is connected to the output end of No. 2 motor 9 Hinge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com