Blister machine table automatic backing plate

A technology of workbench and blister machine, which is applied in the field of automatic padding of blister machine workbench, which can solve the problems of burden, large amount of maintenance, scrapping of board parts, etc., achieve less support unit parts, save manufacturing cost, and reduce motion load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

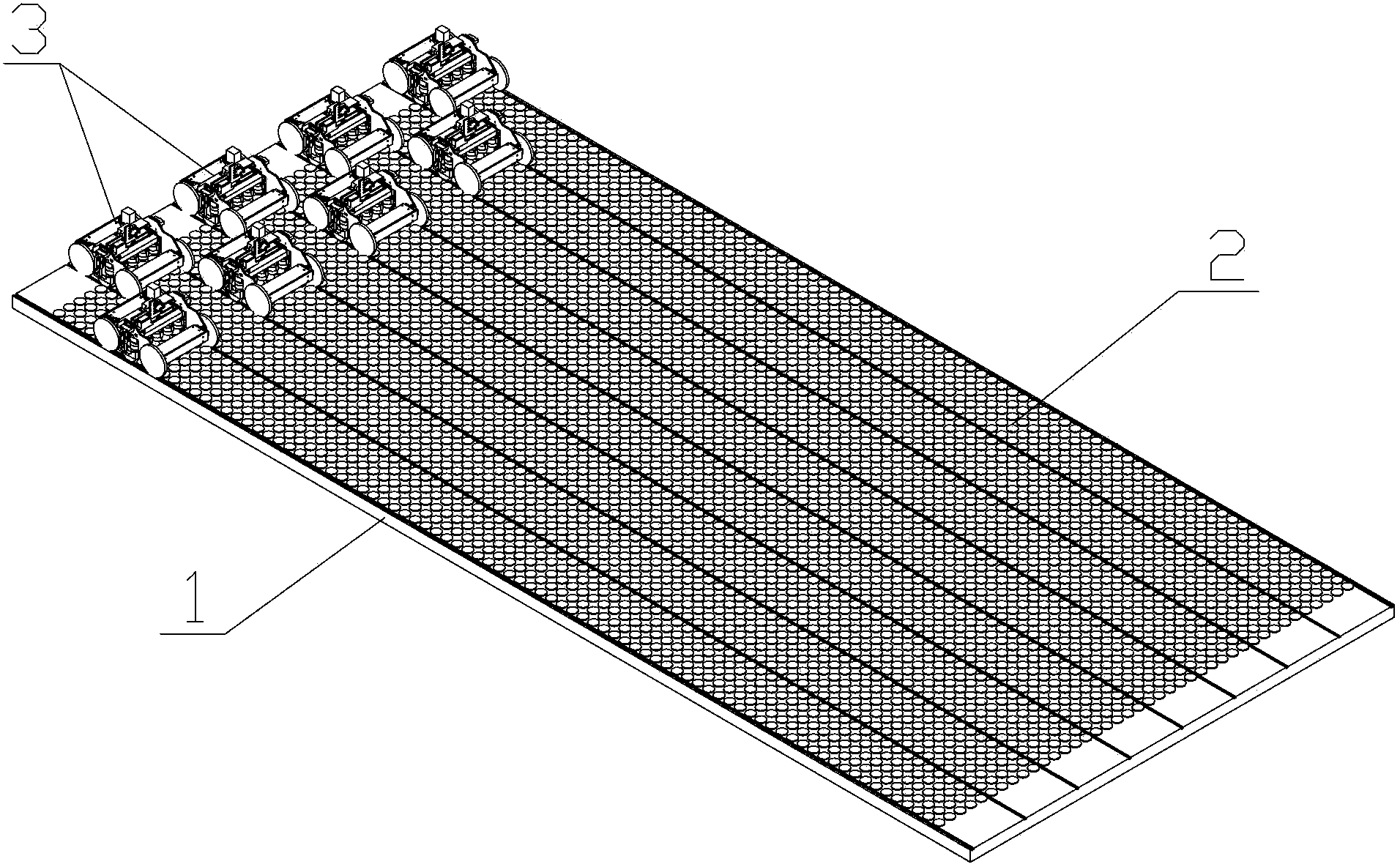

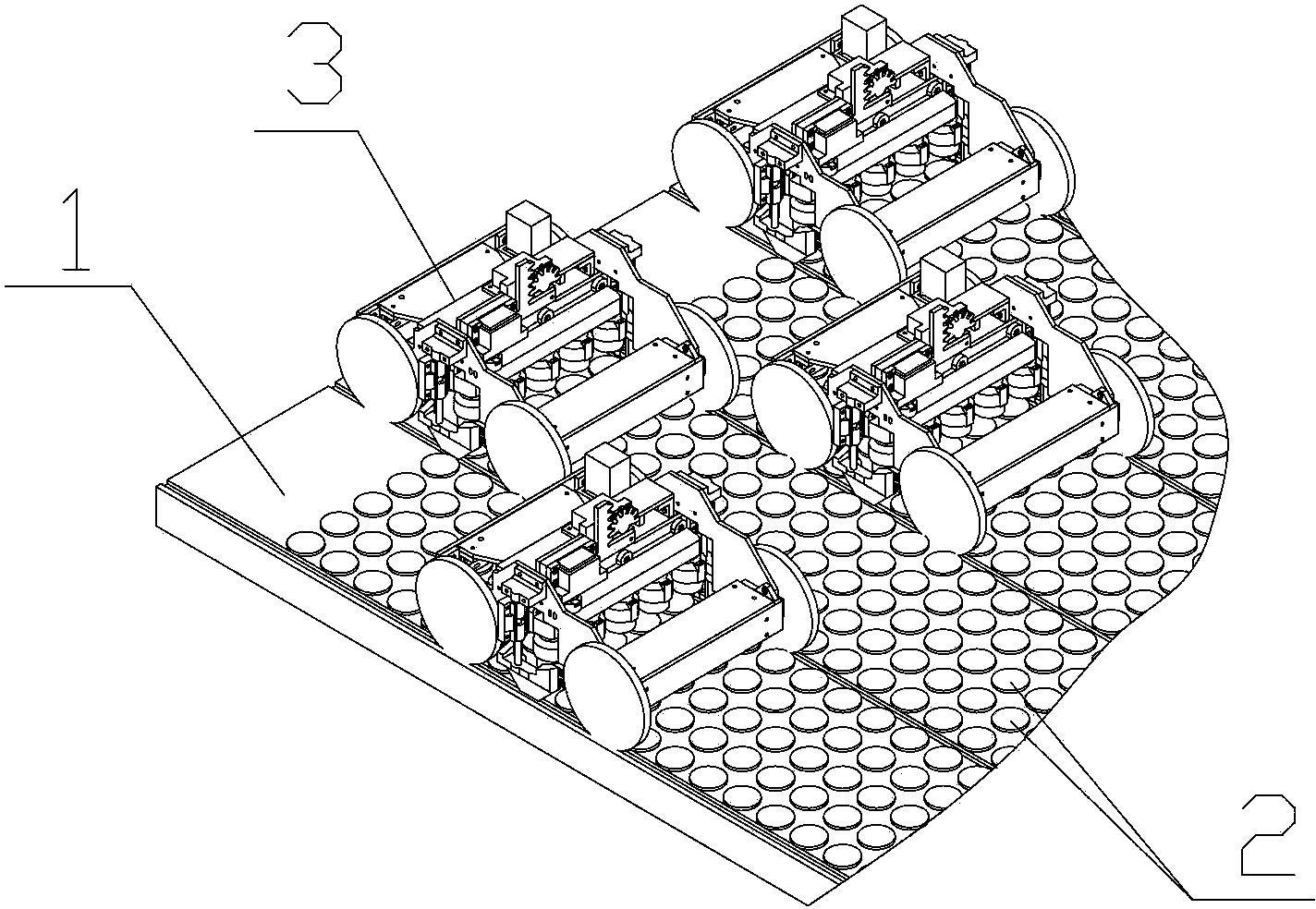

[0037] See figure 1 with figure 2 The automatic backing board of the workbench of the blister machine of this embodiment includes a backing board 1, a plurality of supporting units 2 arranged on the backing board 1, and a plurality of operating robots 3. among them,

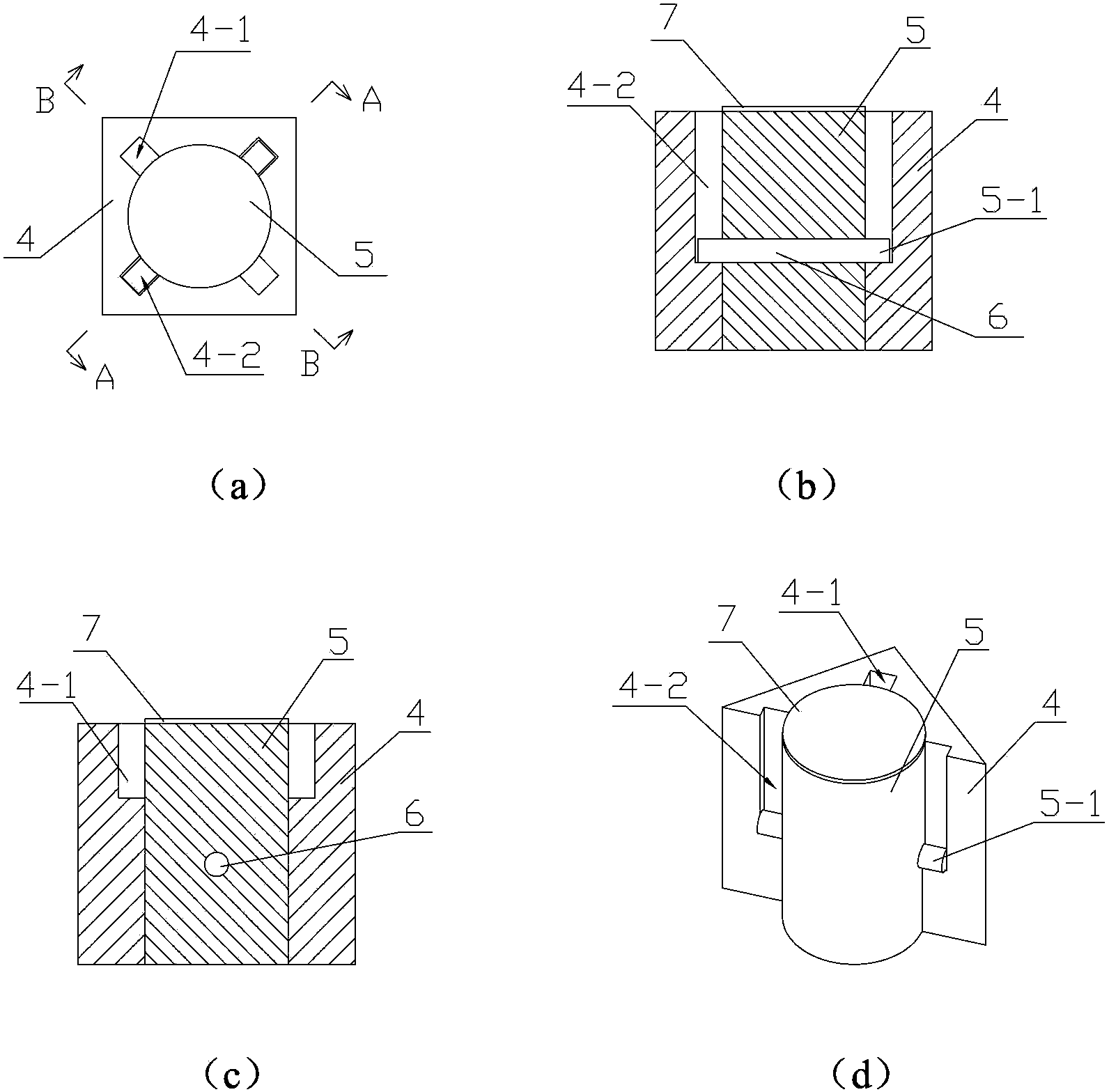

[0038] See image 3 with Figure 4 The support unit 2 includes a support base 4 and a support rod 5 that can move up and down in the support base 4. The support rod 5 is a cylinder inserted into a cylindrical hole in the support base 4. 4 and the support rod 5 are provided with a locking structure, which allows the support rod 5 to stay and support in a raised position when moving upwards to form a raised state, and to stay and support in a lowered position when moving downwards A descending state is formed; specifically, the locking structure is: two sets of sink grooves with different axial depths are provided on the wall of the cylindrical hole, wherein the smaller depth is the upper sink groove 4-1, and the lar...

Embodiment 2

[0044] See Figure 10 ~ Figure 12 The difference between this embodiment and embodiment 1 lies in the locking structure in the support unit 22. The locking structure of this embodiment is: the bottom surface of the cylindrical hole of the support base 4 is provided with a downwardly recessed rectangular groove 4- 4. The bottom surface of the circular hole forms an upper positioning step, and the bottom of the groove 4-4 forms a lower positioning step; the circumference of the bottom of the cylindrical hole extends radially outward, so that the bottom of the cylindrical hole forms a rectangular space 4 -3, and at the two opposite corners of the rectangular space 4-3 are provided with blocking portions 4-5, the inner edge of the blocking portion 4-5 extends beyond the side wall of the cylindrical hole, the role of the blocking portion 4-5 is set It limits the rotation range of the support rod 5 in the cylindrical hole; the middle of the bottom surface of the cylindrical support r...

Embodiment 3

[0048] See Figure 13 with Figure 14 In this embodiment, the locking structure is: the support rod 5 is a bolt, and the support seat 4 is provided with a nut 8 matching the bolt; the bolt realizes up and down movement when it rotates relative to the nut 8. The raised position and the lowered position are within the range of the up and down movement of the bolt, so that when the support rod 5 moves up to the raised position, it forms a raised state, and when it moves down to the lowered position, it forms a lowered state.

[0049] See Figure 14 with Figure 15 The difference between the operating machine of this embodiment and this embodiment 1 is that the operating head of this embodiment adopts the in-line transmission member 25 as the operating element that drives the support rod 5 to move, thereby replacing the operating element in embodiment 1. The lower part of the flat-shaped transmission member 25 has a flat-shaped screwdriver bit, and the upper part is a cylinder, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com