Laser cladding wire feeding device

A technology of laser cladding and wire feeding device, applied in the direction of metal material coating process, coating, etc., can solve the problems of increasing the instability of wire feeding, large size of wire feeding mechanism, and failure of wire to pass smoothly, and achieve wire feeding. Stable and reliable, the installation structure is simple and easy to use, and the effect of reducing volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, so that those skilled in the art can understand the present invention more clearly, but the protection scope of the present invention is not limited thereby.

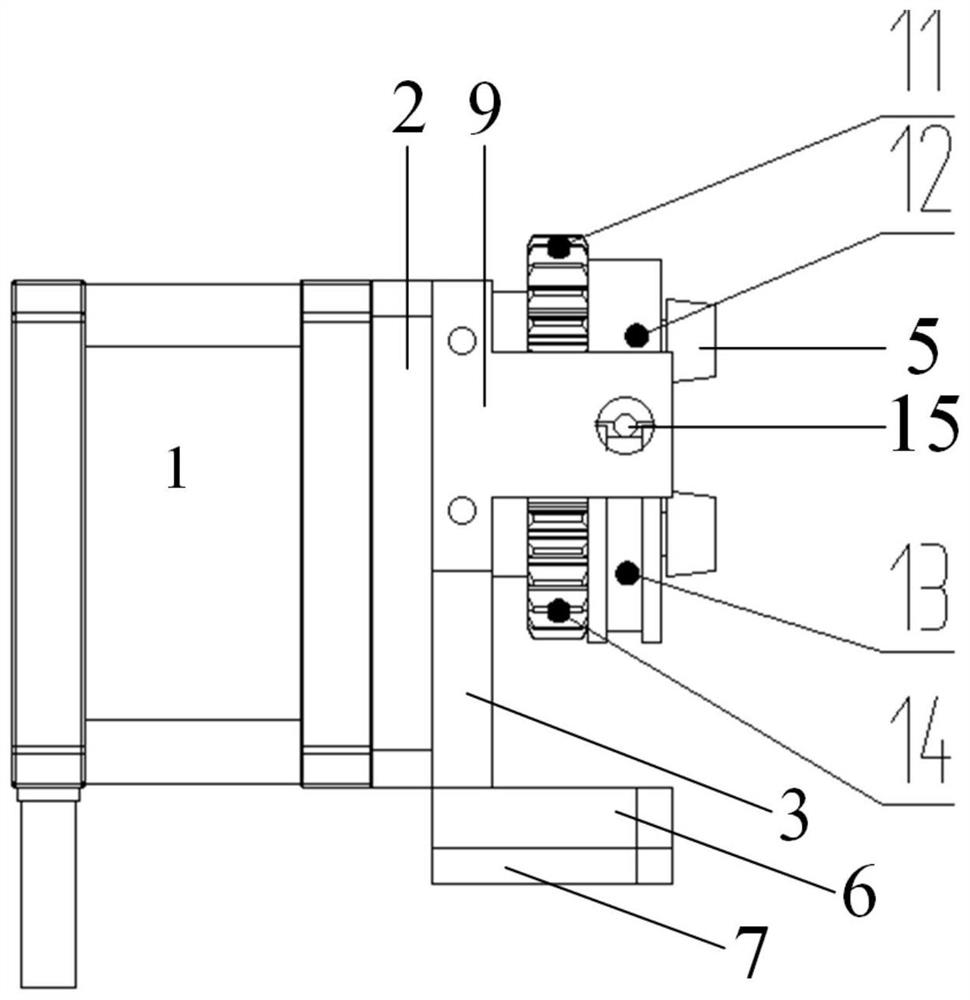

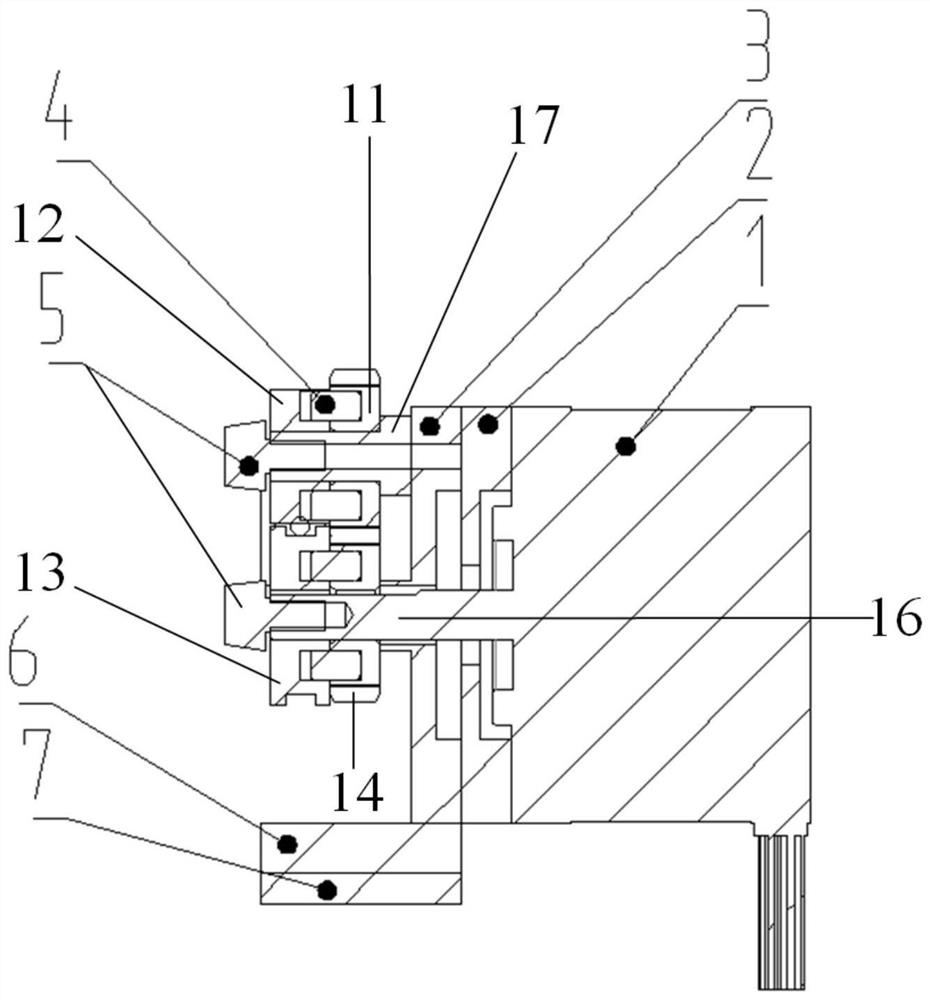

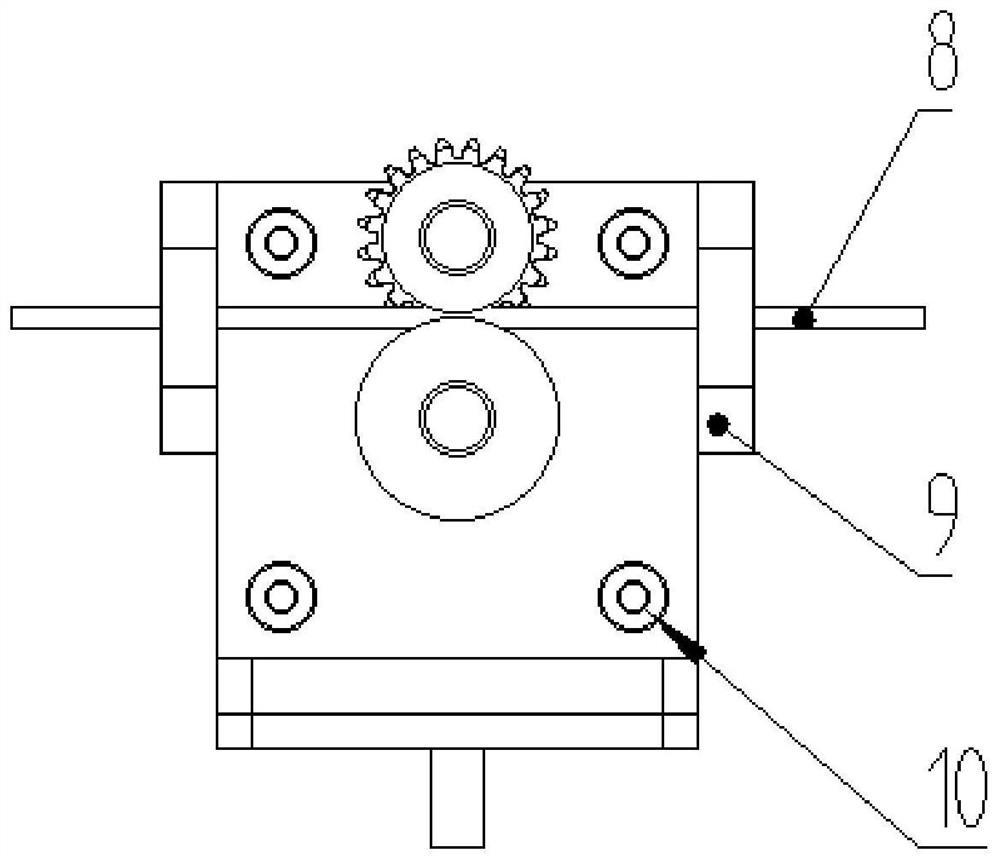

[0027] The present invention proposes a laser cladding wire feeding device, as attached figure 1 As shown, the laser cladding wire feeding device includes: motor 1, first insulating block 2, motor mounting flange 3, positioning pin 4, roller nut 5, flange mounting plate 6, second insulating block 7, wire Material 8, wire material through-hole part 9, insulating sleeve 10, driven wheel 11, wire pressing wheel 12, wire feeding wheel 13, driving wheel 14.

[0028] The motor mounting flange 3 is mounted on the motor 1, and the first insulating block 2 is mounted between the motor 1 and the motor mounting flange 3, and serves as an insulation function between the motor and the flange. The motor 1 and the motor mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com