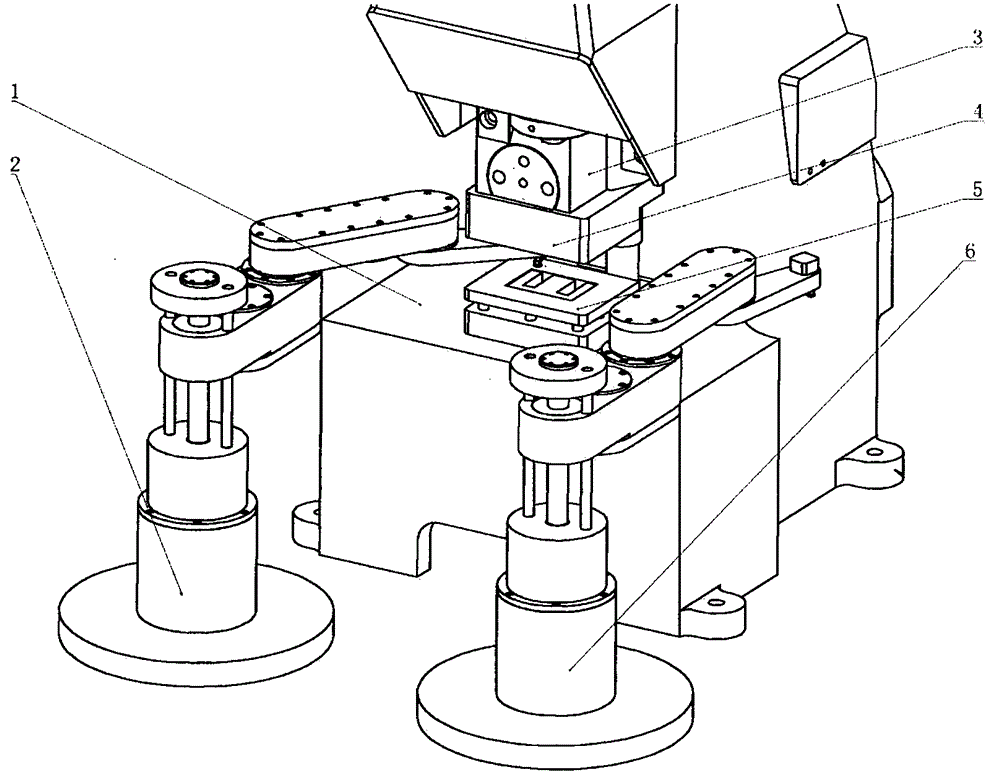

Loading/unloading mechanical arm system for slice part punching

A technology of mechanical arm and stamping processing, which is applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of low production efficiency, harsh working environment, and high labor intensity of workers, so as to improve service life, save space, cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

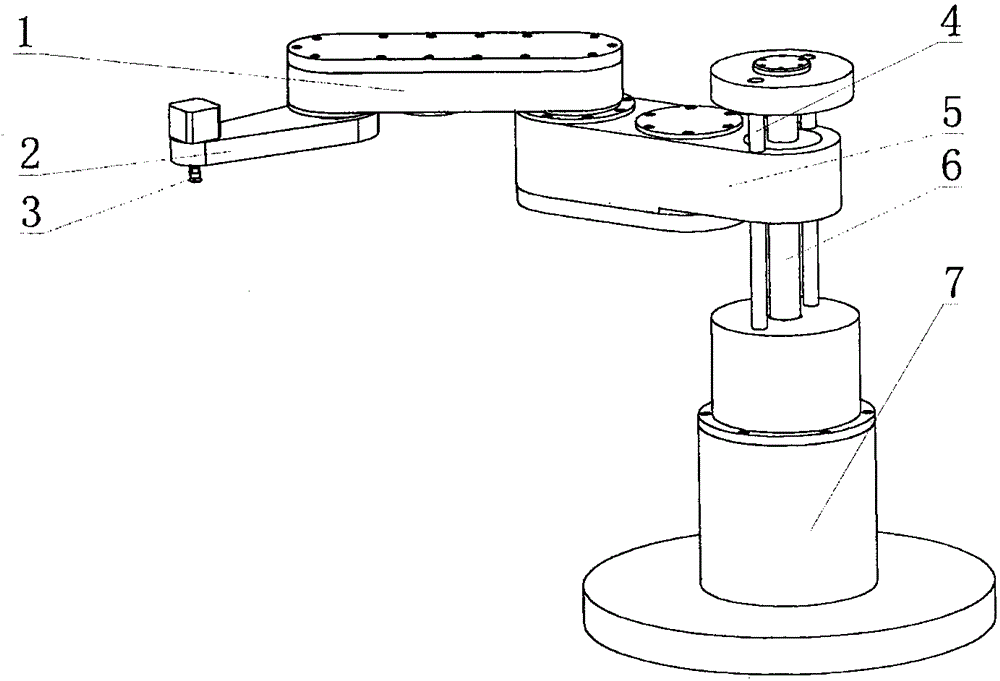

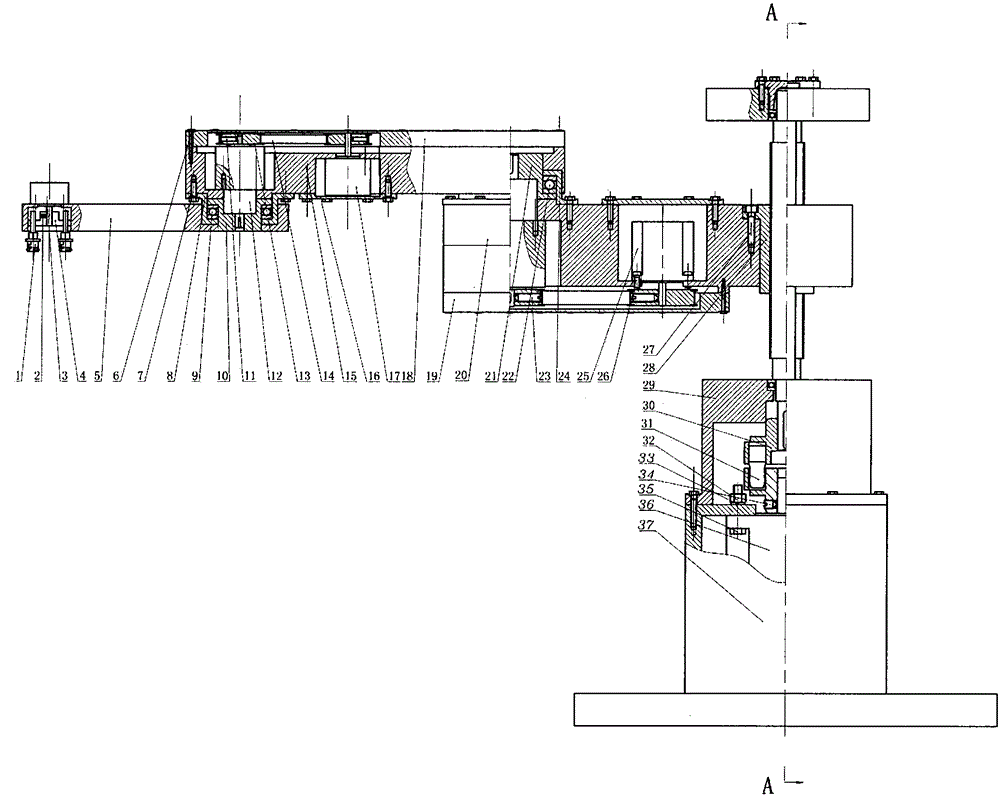

[0023] The following is attached image 3 , 4 further illustrate the specific structure and working mode of the present invention.

[0024] The loading and unloading robotic arms respectively have four degrees of freedom, one of which is moving and three rotating. The lifting table (20) can realize linear movement, while the large arm of the mechanical arm (15), the small arm of the mechanical arm (5) and the hand rest (4) can realize rotational movement. The stepping motor 4 (36) that is installed in the base 2 (29) transmits power to the screw shaft (43) through the shaft coupling (30), and the screw shaft (43) rotates so that the lifting platform (20) moves between the two The up and down movement is realized under the restriction of the guide column (41); the stepper motor 3 (25) installed in the lifting platform (20) transmits the power to the upper arm (15) of the mechanical arm through the synchronous toothed belt and the harmonic reducer , so as to realize the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com