Space thin-wall part material increasing and decreasing multi-station synchronous machining method and device

A technology of synchronous processing, adding and subtracting materials, applied in the direction of metal processing equipment, manufacturing tools, and other manufacturing equipment/tools, etc., can solve the problems of incomplete function of material reduction and low flexibility of material reduction processing, so as to relieve constraints and improve production Flexibility, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

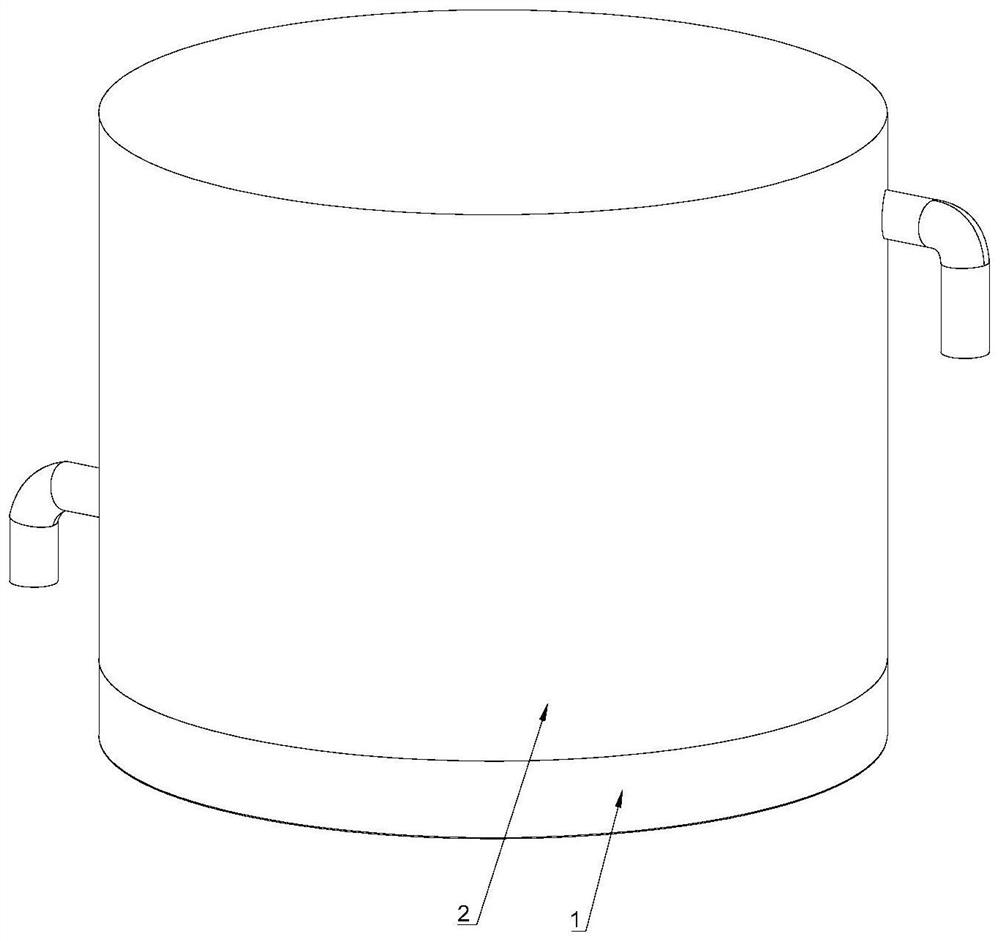

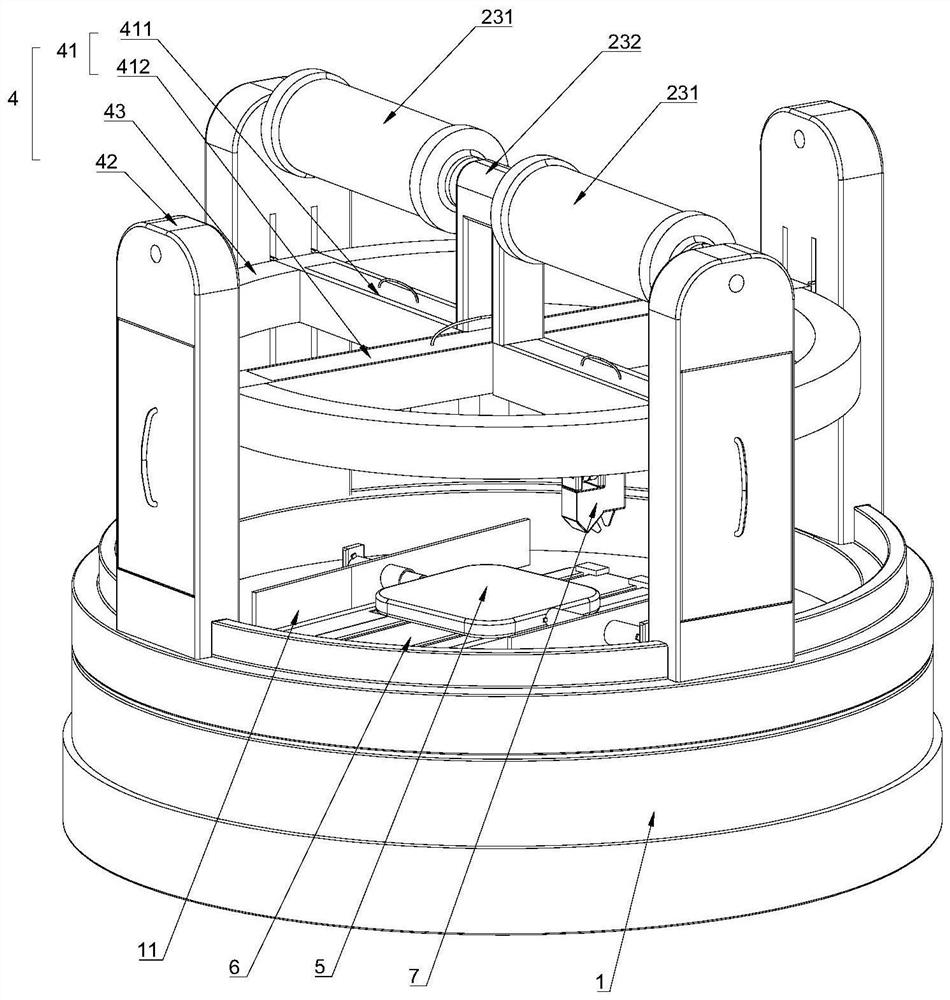

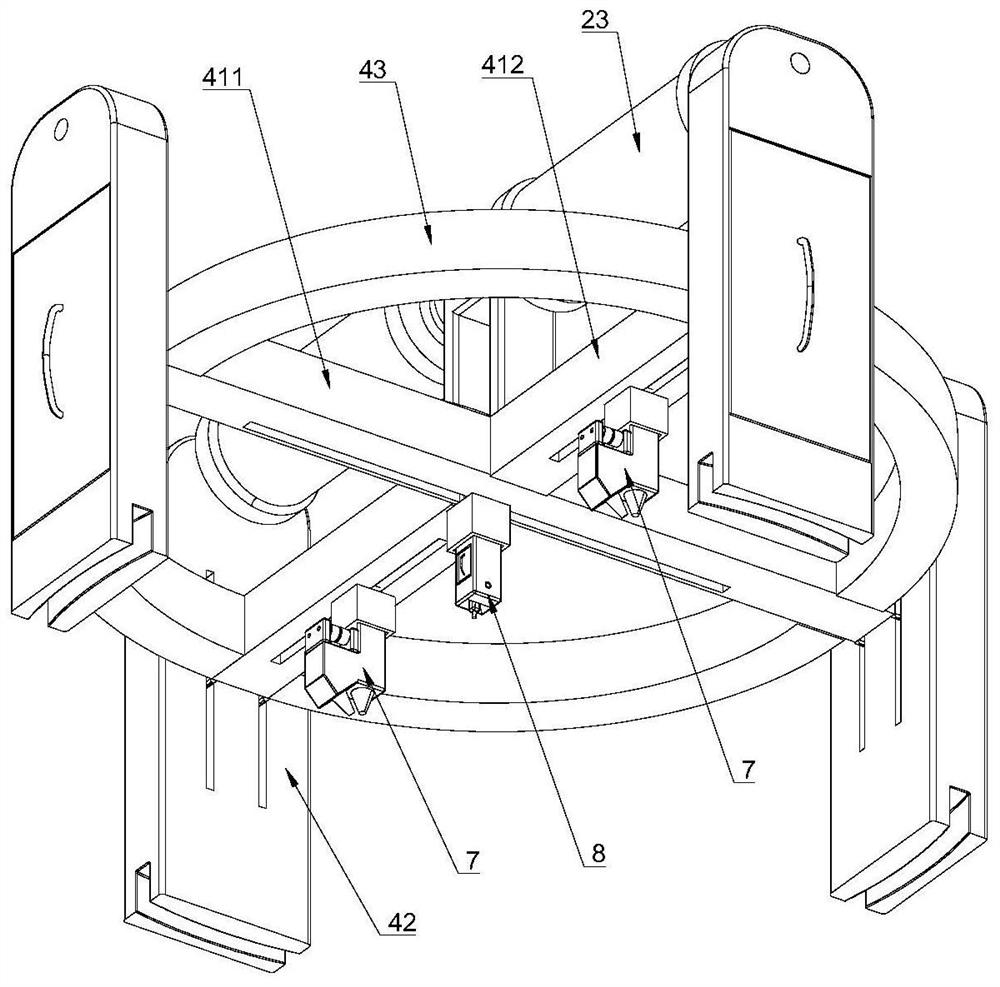

[0077] like Figures 1 to 27As shown, a multi-station synchronous processing device for adding and subtracting materials of thin-walled components in space according to the present invention includes a fixed base 1, a gantry crane 4, a material adding module 7, a grinding and cutting material module 8, and a composite workbench; the fixed base 1 includes The inner base 101, the upper base 103 and the lower base 104, the inner base 101, the upper base 103 are located on the lower base 104, the upper base 103 is sleeved on the outside of the inner base 101; the fixed base 1 is provided with a sixth driving mechanism 3, and the upper base 103 is driven by the sixth drive mechanism 3 to rotate relative to the inner base 101, the gantry crane column 42 is fixed on the upper base 103, and the compound workbench is arranged at the inner base 101; the compound workbench includes an upper workbench 5 and a lower workbench 6 , the lower table 6 is connected to the bottom of the upper ta...

Embodiment 2

[0120] Figures 29 to 32 As shown, a multi-station synchronous processing device for adding and subtracting materials of thin-walled spare parts in this embodiment is roughly the same as that in Embodiment 1, except that:

[0121] In this embodiment, the beam 41 of the gantry crane is provided with a laser material reduction module 70 under the end of the side close to the column 42 of the gantry crane. The laser material reduction module 70 is used to perform material reduction processing on the side of the workpiece.

[0122]The laser material reduction module 70 is at the end of the gantry crane beam 41 (including the first beam 411 and the second beam 412), including a material reduction laser head and a material reduction support, one end of the material reduction support is connected to the gantry crane beam 41, and the other end is connected to the gantry crane beam 41 The material reduction laser head is connected, and the material reduction laser head can rotate along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com