Hydraulic control system for parallel six-degree-of-freedom turntable

A technology of hydraulic control system and degree of freedom, applied in the field of position servo system, can solve the problems of unsolved dynamic problems, difficult to eliminate coupling interference between the branches of the platform, etc., to achieve the effect of large stiffness, small error and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in more detail below in conjunction with accompanying drawing example:

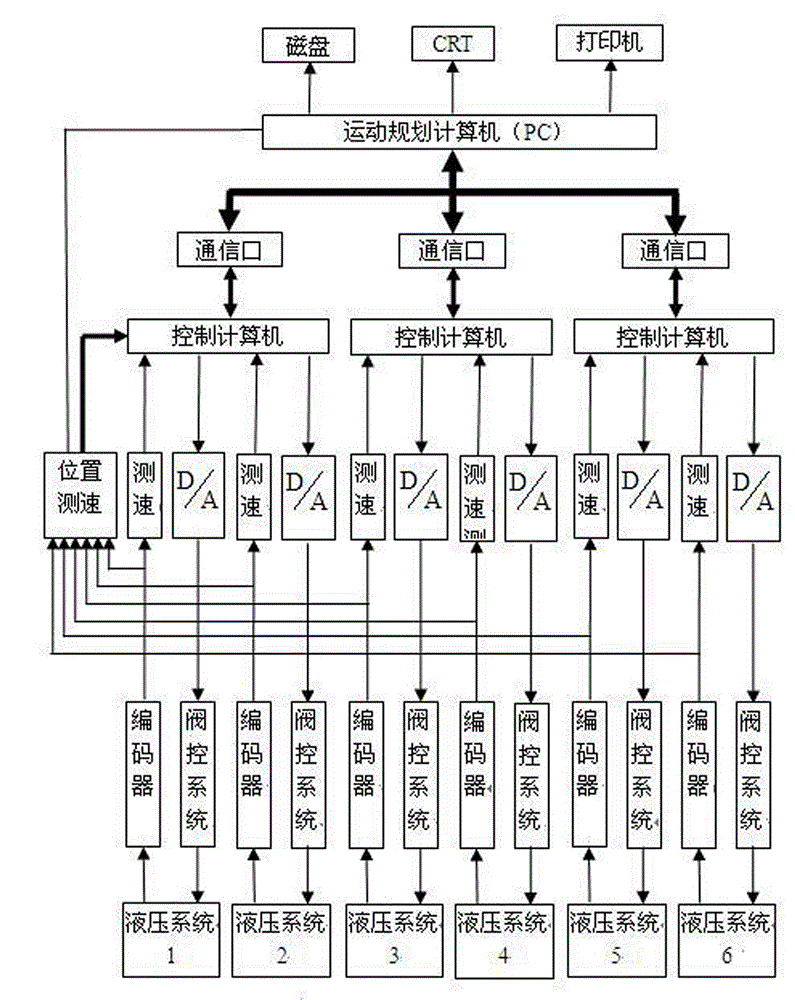

[0043] combine figure 1 , figure 1 It is the structure diagram of the turntable control system. The invention is mainly composed of a motion planning computer, a direct control computer, a communication interface, a position and speed detection component, a D / A conversion and power amplifier, and an electro-hydraulic servo valve.

[0044] The main functions of each part of the turntable control system are as follows:

[0045] 1. Motion planning computer

[0046] Directly accept external control commands and parameters, calculate the expansion and contraction value of each hydraulic rod and the speed value of each hydraulic rod length change at each moment to keep the turntable in a stable posture according to the position change of the robot movement, and monitor the robot movement in real time , Display information, issue various control commands to the subor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com