Electron beam drawing apparatus and stage mechanism thereof

A technology of electron beam irradiation and gantry, which is applied in the direction of electron beam welding equipment, welding equipment, metal processing equipment, etc., and can solve the problem of reduced movement accuracy of X gantry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

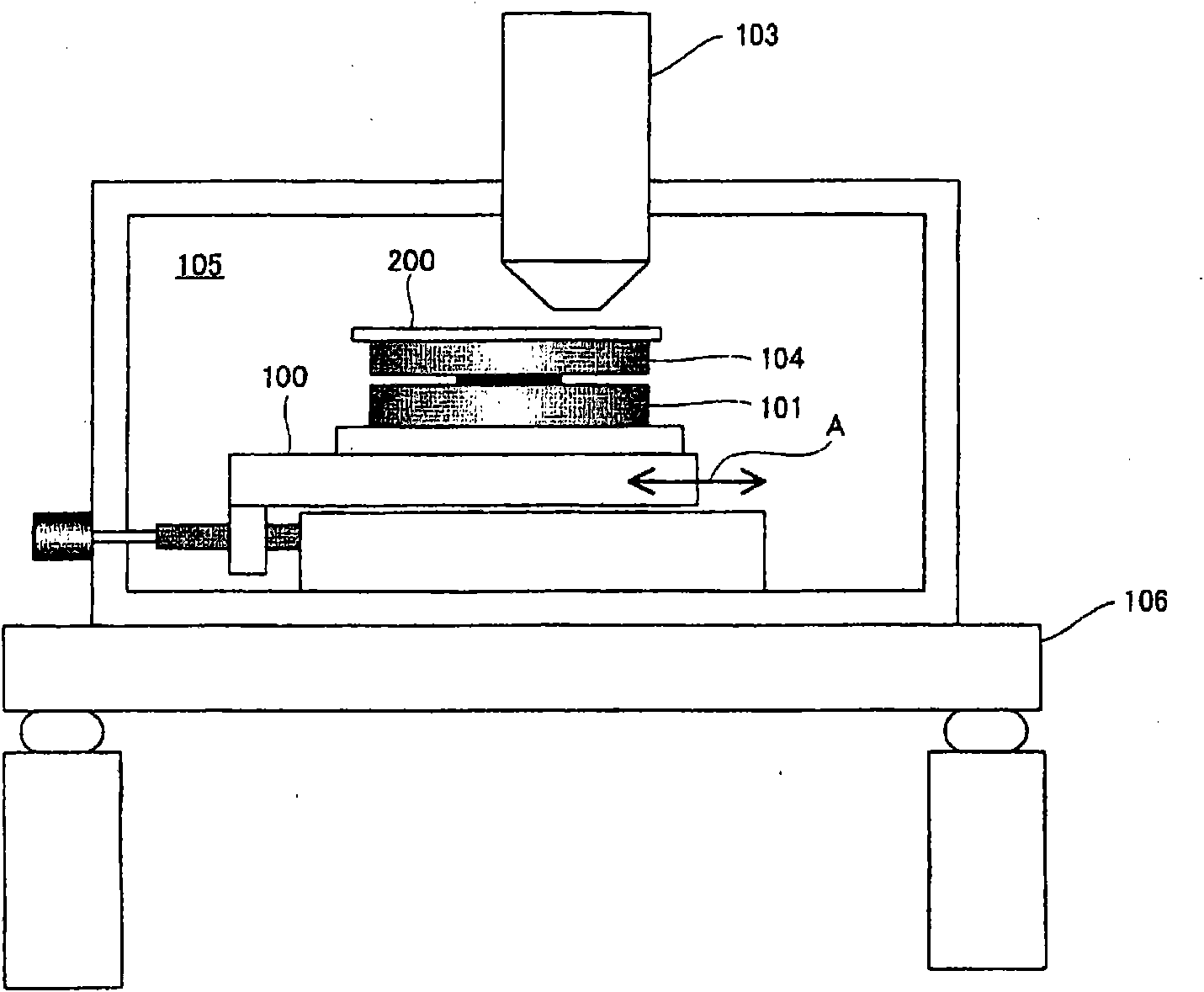

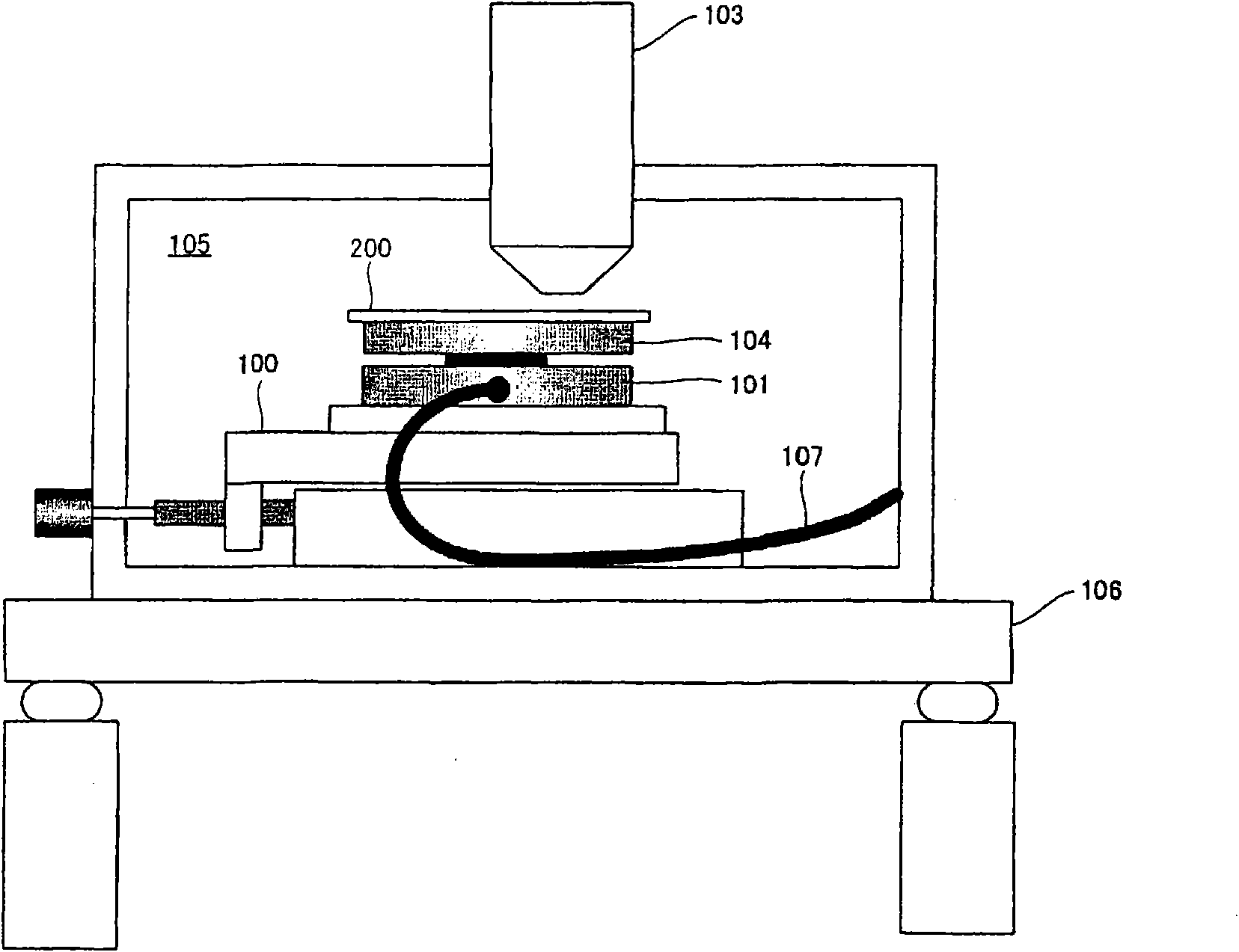

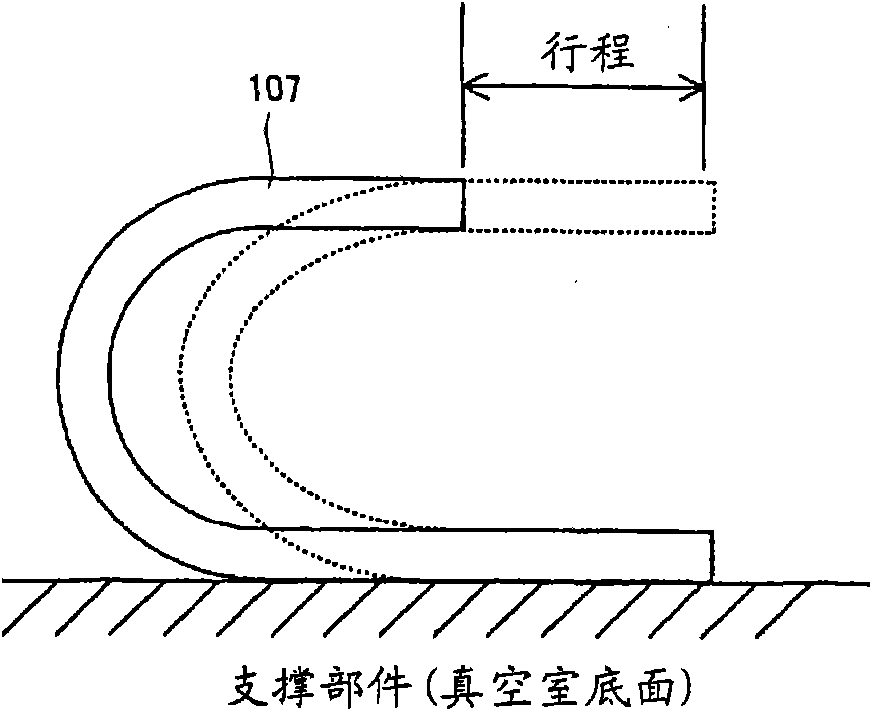

[0033] Embodiments of the present invention will be described below with reference to the accompanying drawings. In all the drawings cited below, the same reference numerals are used to designate substantially the same or equivalent components or parts.

[0034] Figure 4 It is a cross-sectional view of a rotary table 1 using an aerostatic electric spindle as an embodiment of the present invention. The thrust plates 3, 4 and the swivel table 5 are connected to the rotary shaft 2 of the rotary gantry 1, so these parts form a rotary part. A journal bearing 6 and a thrust bearing 7 are placed facing the rotary shaft 2 and the thrust plates 3 , 4 with a slight gap, respectively. When the compressed air is supplied into the bearing inlet 8 , the compressed air is ejected via the supply passage 9 out of nozzle forming portions forming parts of the journal bearing 6 and the thrust bearing 7 . The rotary shaft 2 and the thrust plates 3 and 4 are supported by the compressed air in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com