Quasi-SCARA (Selective Compliance Assembly Robot Arm) industrial robot

An industrial robot, a type of technology, applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of inability to realize lifting movements such as suction and discharge, and can not be used, so as to simplify design complexity, reduce height, and reduce The effect of moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

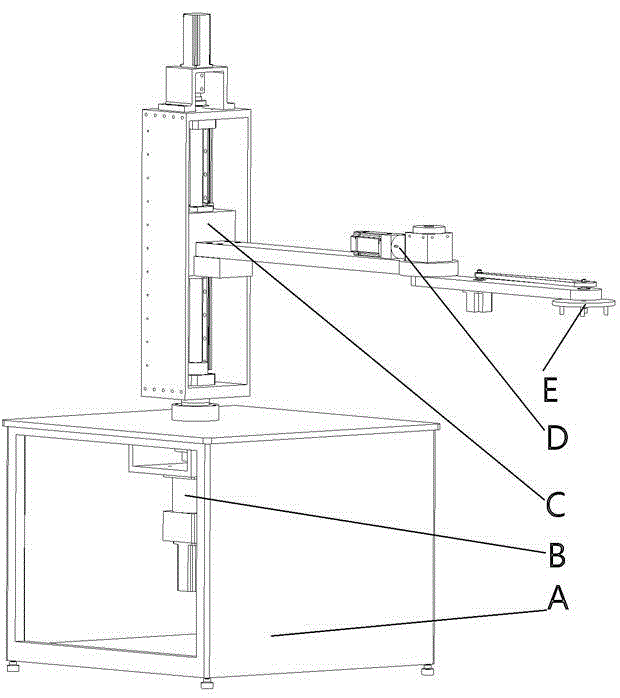

[0030] Such as figure 1 As shown, a type of SCARA industrial robot includes a base A, a whole arm rotation mechanism B, a vertical movement mechanism C, a small arm rotation mechanism D and an execution end rotation mechanism E, and the whole arm rotation mechanism B is fixed on the base A , the vertical movement mechanism C is installed on the whole arm rotation mechanism B, the whole arm rotation mechanism B drives the vertical movement mechanism C to rotate, the small arm rotation mechanism D is fixed on the vertical movement mechanism C, and the vertical movement mechanism C drives the forearm rotating mechanism D to move vertically, the actuator rotating mechanism E is installed on the forearm rotating mechanism D, and the forearm rotating mechanism D drives the executing end rotating mechanism E to rotate, forming a serial industrial robot structure.

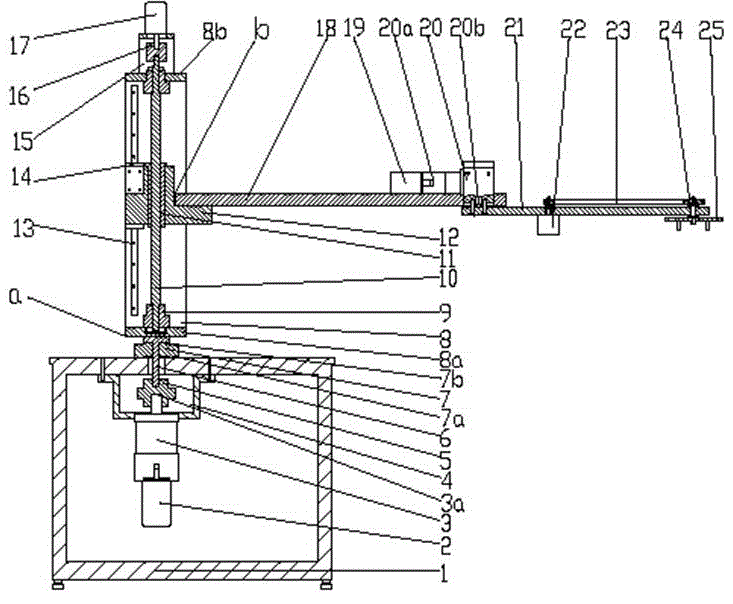

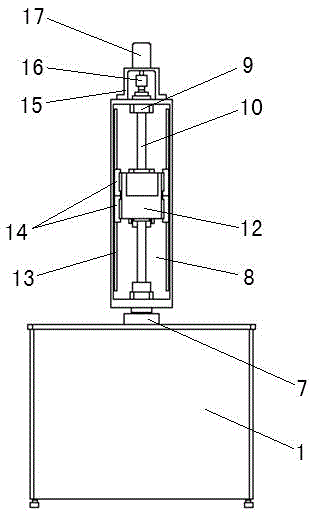

[0031] In the embodiment of the present invention, as Figure 2A , 2B , 2C, the whole arm rotating mechanism B include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com