Single-leg robot jumping mechanism driven through connecting rod

A connecting rod transmission and robot technology, applied in the field of robots, can solve the problems of weak energy storage effect and can only jump in place, and achieve the effects of reducing energy consumption, improving stability and agility, and reducing moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

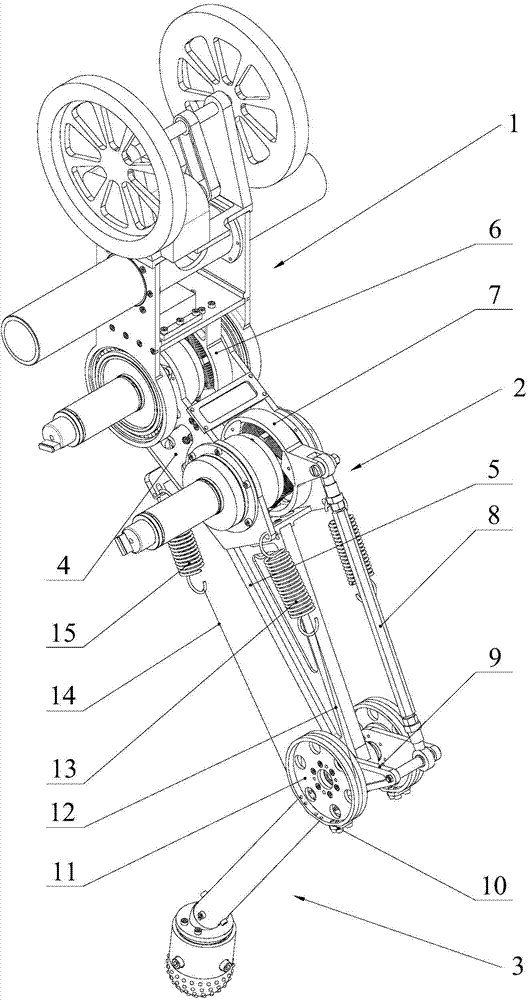

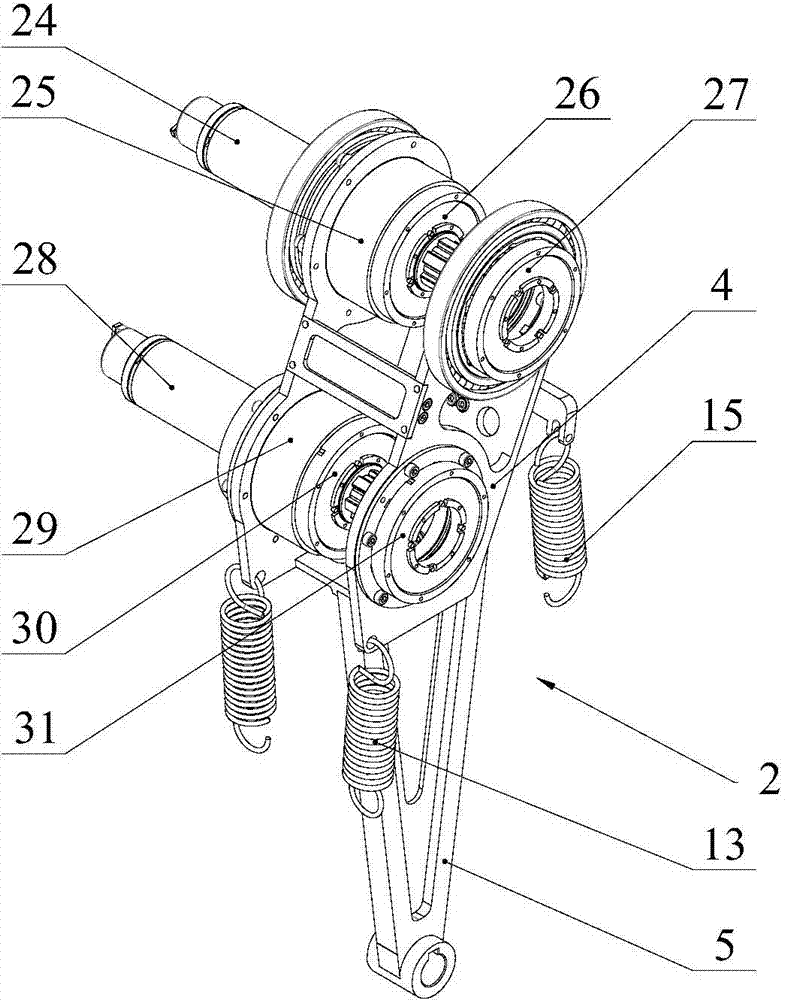

[0045] like Figure 1~4 As shown, a link-driven single-leg robot jumping mechanism includes a fuselage 1, a thigh 2 and a calf 3 that are hinged in sequence. The thigh is provided with a jumping drive device that drives the leg to rotate and a directional drive device that drives the thigh to rotate.

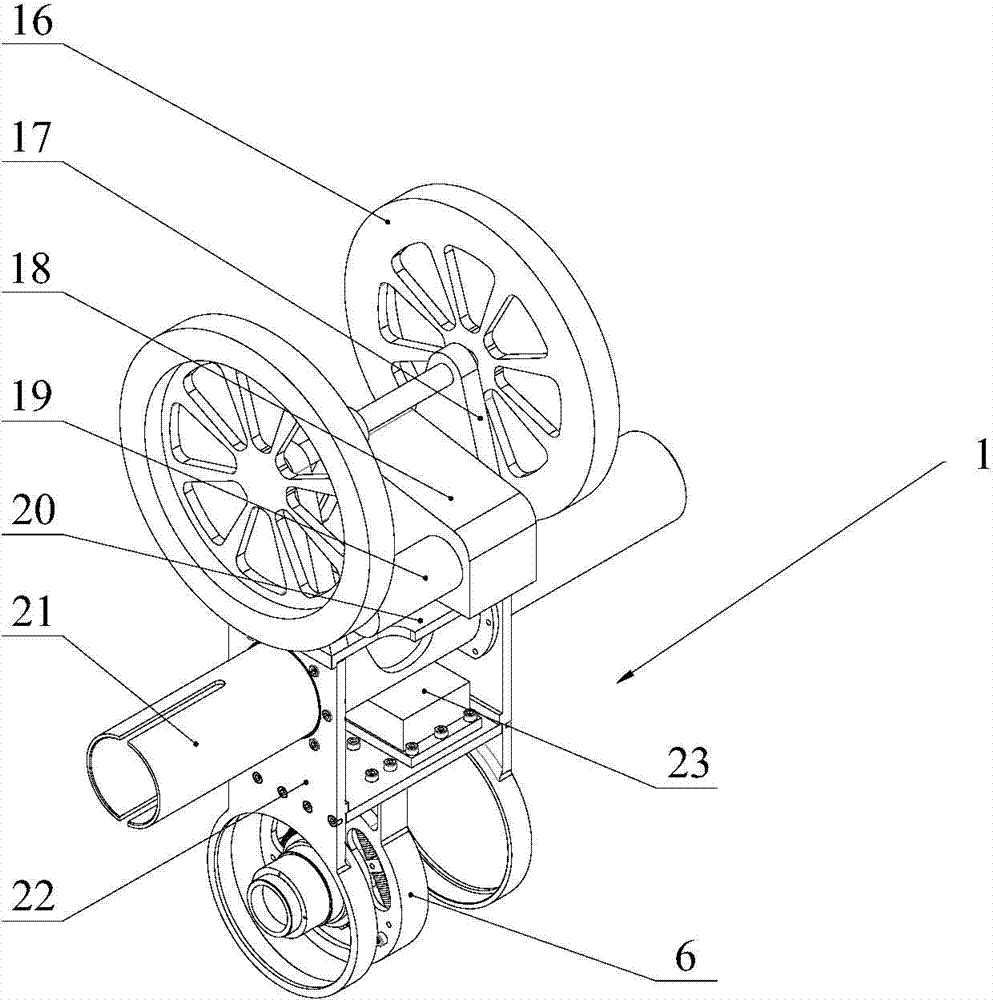

[0046] like figure 2 As shown, the fuselage 1 includes a base 20, a balance flywheel 16 connected to the base and a gyroscope 23 fixed on the base, and a flywheel motor 19 and a flywheel reducer 18 that cooperate with each other are also fixed on the base, The output shaft of the flywheel reducer drives the balance flywheel to rotate through the synchronous belt 17. The base 20 is also provided with two side splints 22 arranged symmetrically. The side splints are fixed as a whole through the clamping tube 21. Each side splint includes an adapter plate hinged with the thigh. The two adapter plates are directly fixed with First series elastic drive 6 .

[0047] like figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com