Golf club head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

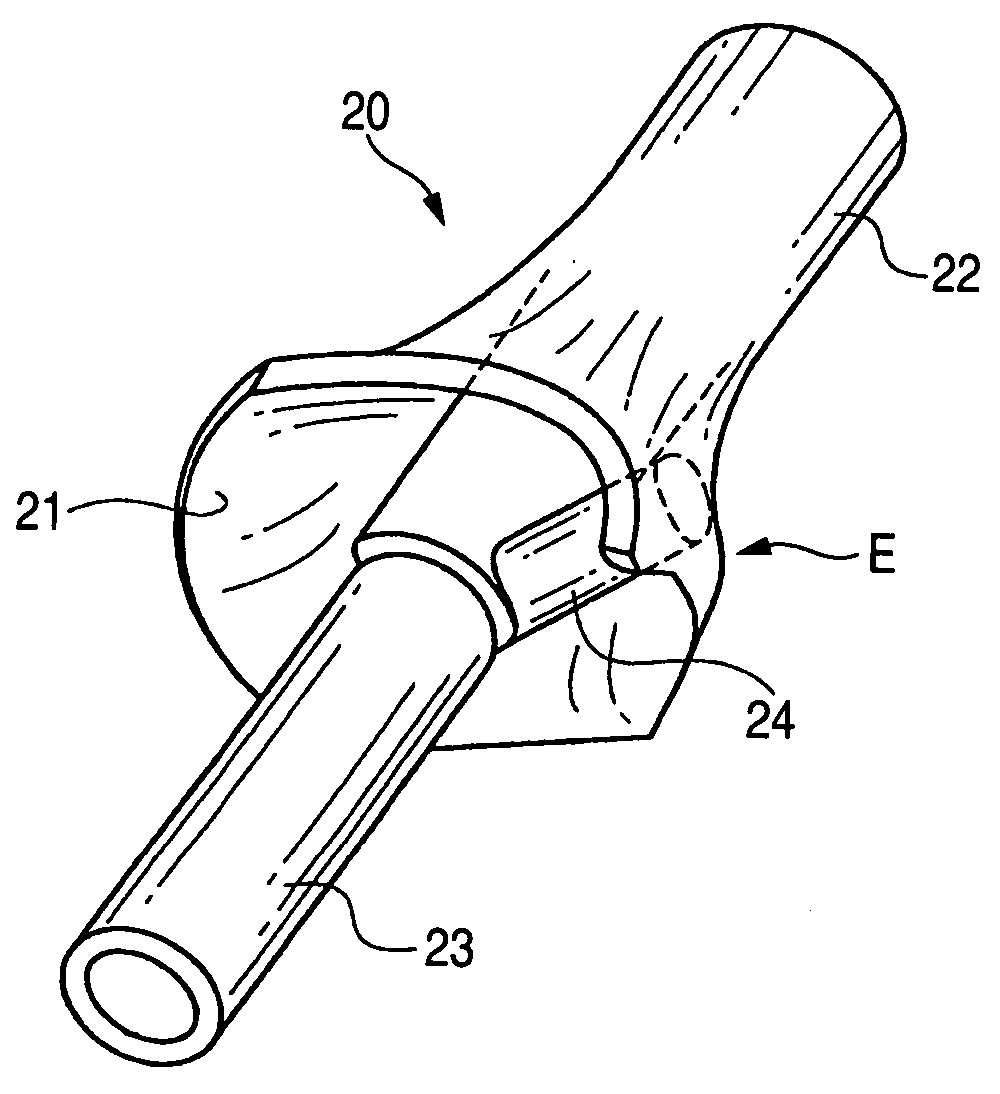

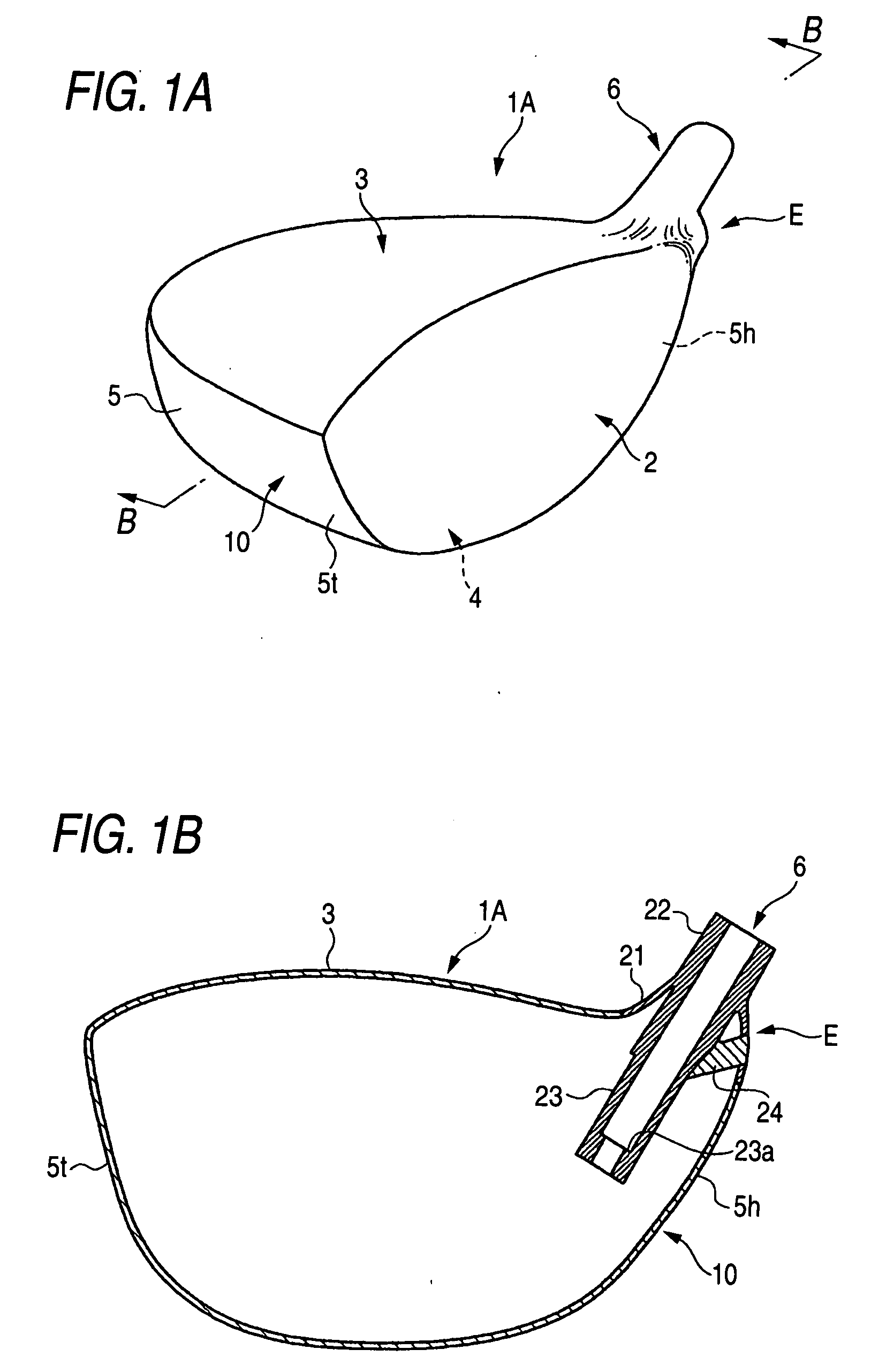

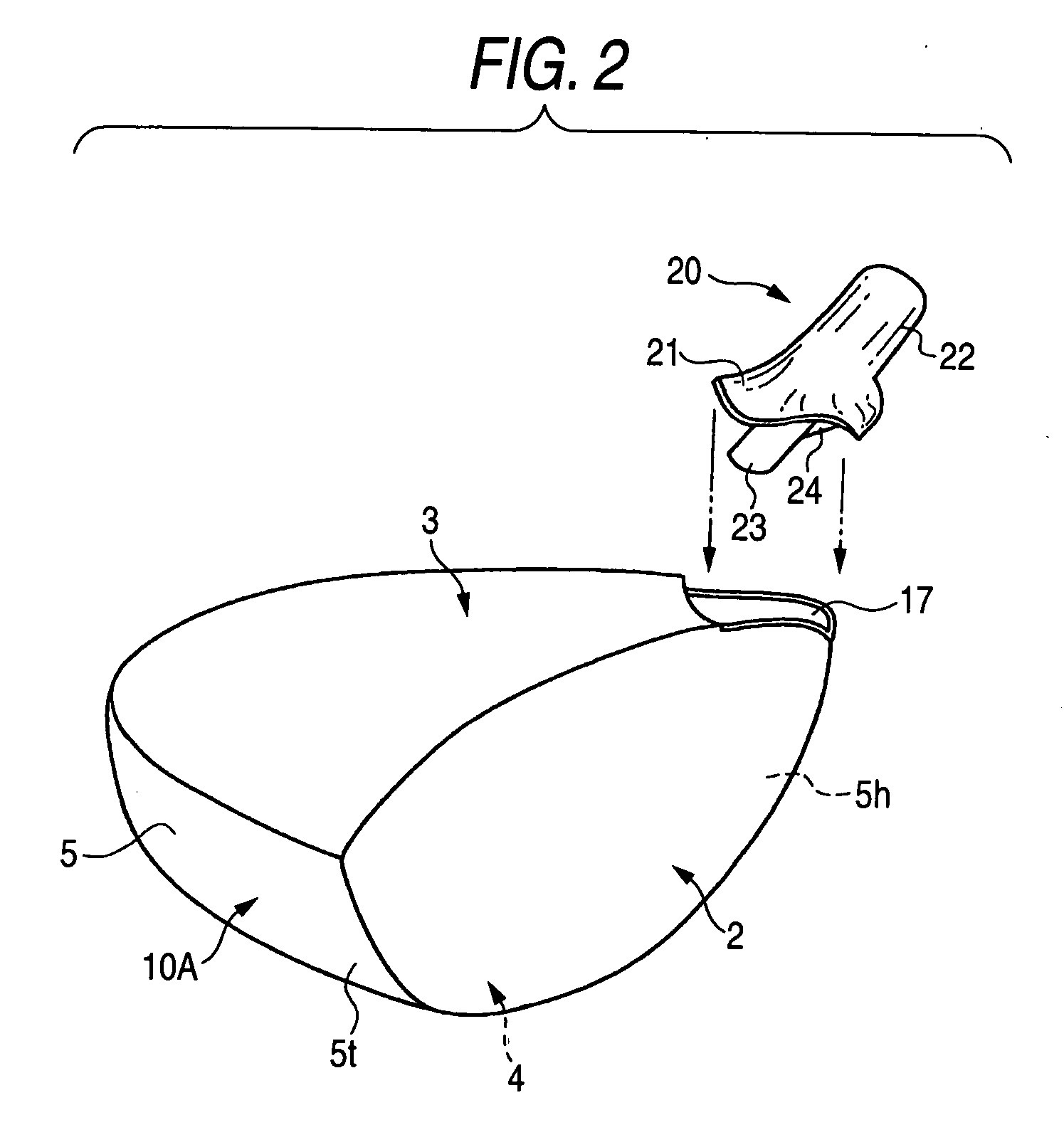

[0047] The preferred embodiments of the present invention will be described below with reference to the accompanying drawings. FIG. 1A is a perspective view of a golf club head according to the invention, and FIG. 1B is a cross-sectional view of the golf club head as shown in FIG. 1A. FIG. 2 is an exploded perspective view of the golf club head. FIG. 3 is a perspective view of a hosel part.

[0048] The golf club head 1A includes a face portion 2, a crown portion 3, a sole portion 4, a side portion 5, and a hosel portion 6. Reference sign 5t denotes a toe side of the side portion 5, and 5h denotes a heel side of the side portion 5. The golf club head 1A is configured with metallic main body parts 10A having a hollow shell shape and a hosel part 20, which are integrated by arc welding, electron beam welding, laser welding or plasma welding.

[0049] A mounting portion 17 for the hosel part 20 is provided on an upper face of the main body parts 10A on the heel side. This mounting portion 1...

second embodiment

[0063] As shown in FIG. 5, a golf club head 1B according to the invention has a barrel portion 26 protruding like a branch from the lower column 23 of a hosel part 20B to the heel side, and the weight material 24 inserted into the barrel portion 26. A top end of the barrel portion 26 on the heel side leads to the skirt portion 21. A lid 27 is disposed to close the weight material 24, and welded to the skirt portion 21.

[0064] The lid 27 is preferably made of pure titanium or titanium alloy, but is not limited thereto.

[0065] Though the lid 27 is employed in FIG. 5, the weight material 24 may be secured by caulking or press fitting, an end face of the weight material 24 being exposed from an outer face of the golf club head 1B. In the case, it is preferred that the end face of the weight material 24 is finished to smoothly continue to the surrounding outer face of the head main body.

third embodiment

[0066] As shown in FIG. 6, a golf club head 1C according to the invention has an overhang portion 28 in which the lower column 23 and the skirt portion 21 on the heel side are continuously integrated, with the weight material 24 held in the overhang portion 28. In the embodiment, a counterbore is provided on a lower face of the overhang portion 28, and the weight material 24 is press fit or caulked into the counterbore. The counterbore is provided on the lower face of the overhang portion 28 in FIG. 6, but may be provided on an outer face of the overhang portion on the heel side.

[0067] The other configuration of the golf club head as shown in FIGS. 5 and 6 is the same as in FIGS. 1 to 3. In these figures, the same numerals or signs designate the same or the same parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com