Three-freedom Halback array permanent magnetism sphericity synchronous motor

A technology of synchronous motors and degrees of freedom, applied in the direction of synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, electric components, etc., can solve the lack of technical features, the possibility of implementation, and no motor involved Structural design and other issues to achieve the effect of expanding the application range, increasing the output torque, and reducing friction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

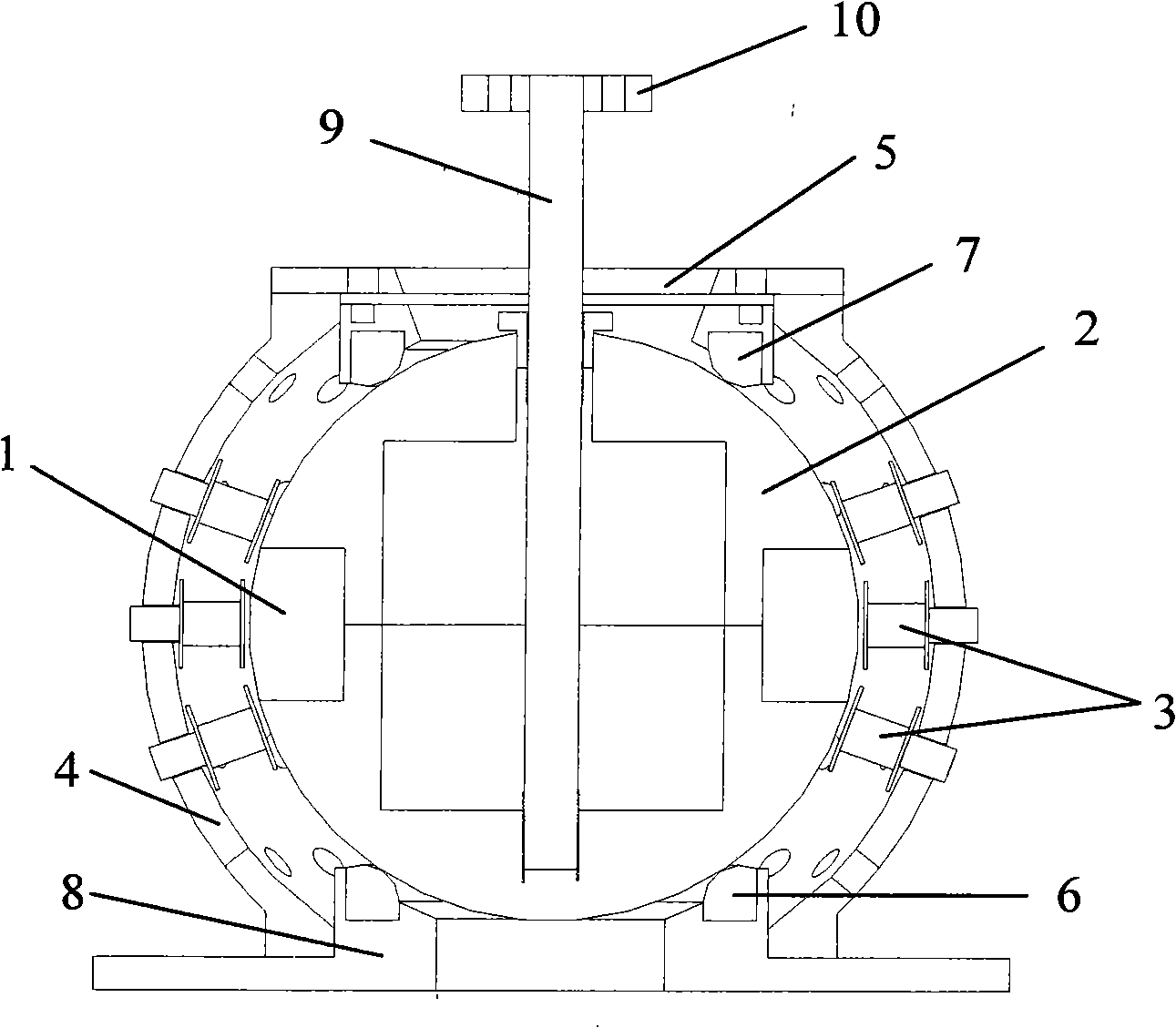

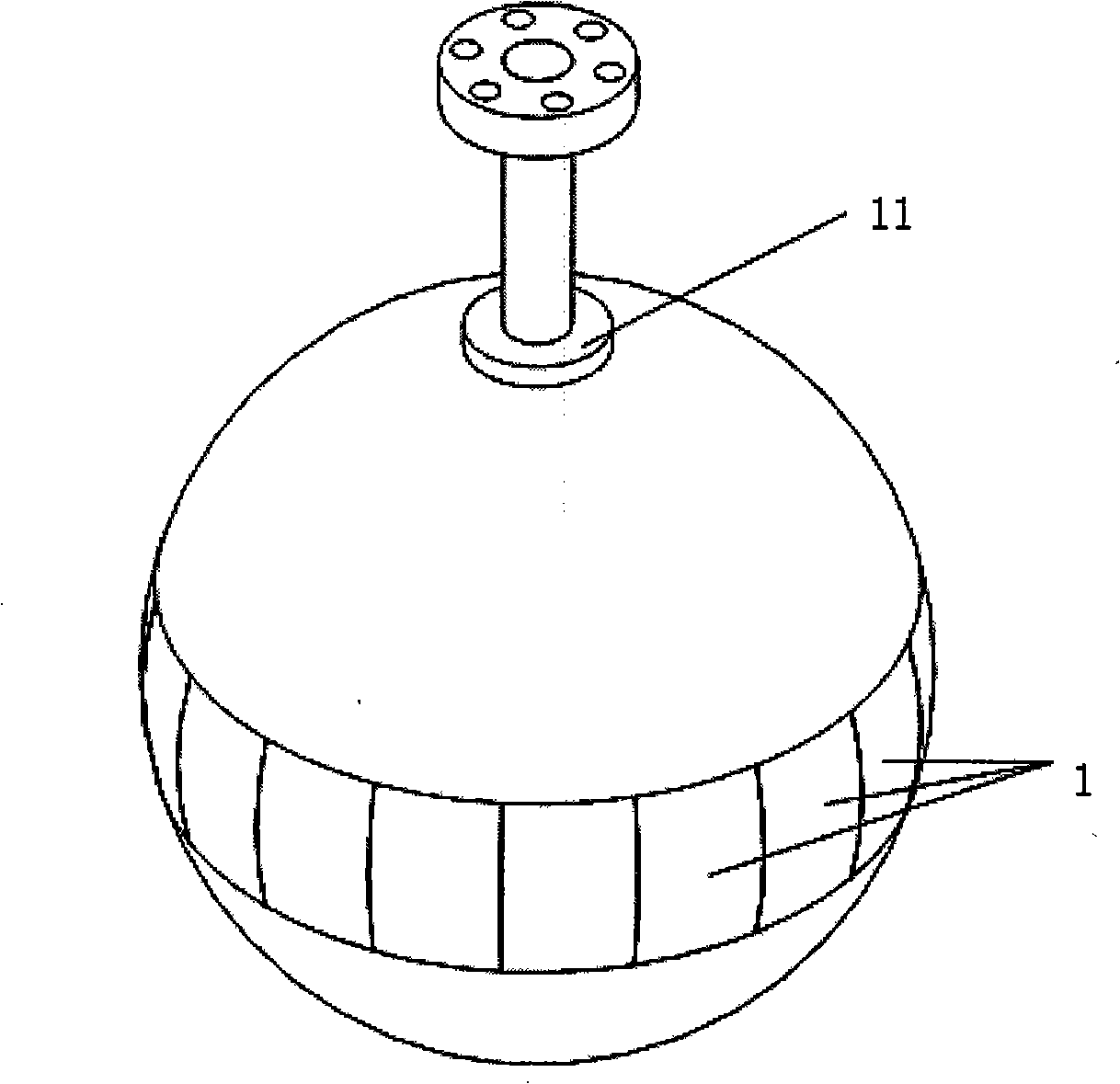

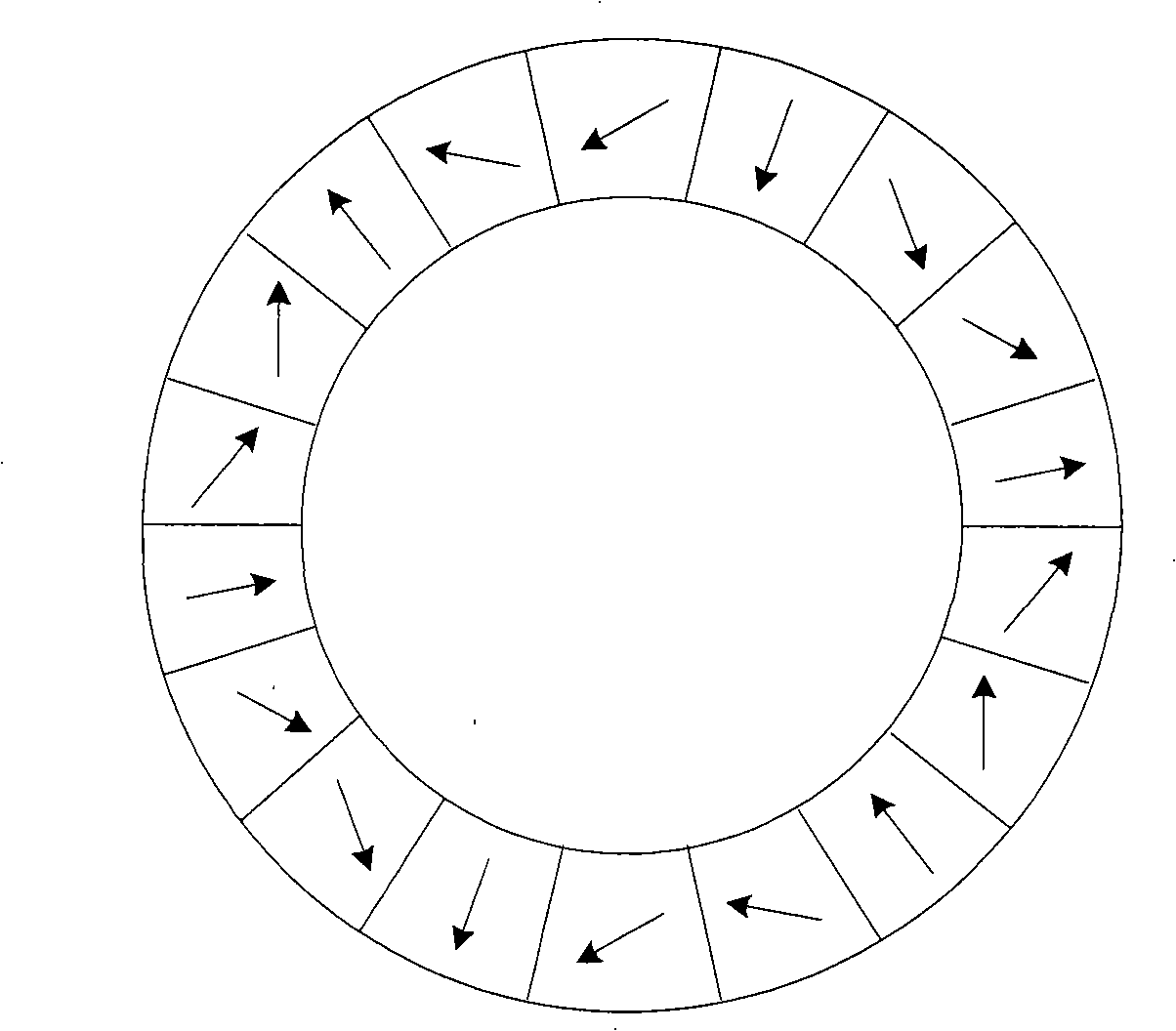

[0020] The present invention proposes a three-degree-of-freedom Halbach array permanent magnet spherical synchronous motor, including a spherical rotor body, an outer stator, a support bearing, a fixed bearing, an output shaft, a base, a flange, etc., wherein the spherical rotor body is made of Halbach array sintered neodymium The iron-boron permanent magnet and the rotor yoke are composed. The outer stator is composed of a spherical stator casing, casing cover and cylindrical coil. The fixed bearing is composed of an annular arc bearing, a bearing seat, a fixing bolt and a spring. It can be adjusted by rotating the bearing fixing bolt. Downforce on the rotor balls. The spherical stator casing has threaded holes along the latitude and longitude of the spherical surface, and all cylindrical coils are respectively fixed on the threaded holes. The air gap between the stator and rotor poles can be adjusted by rotating the coil fixing bolts. According to a certain energization stra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com