Linkage operation device for punched aluminum cover surface convex identifier

A running device and marking technology, applied in stamping, printing, etc., to achieve the effects of easy replacement, convenient and fast stamping, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

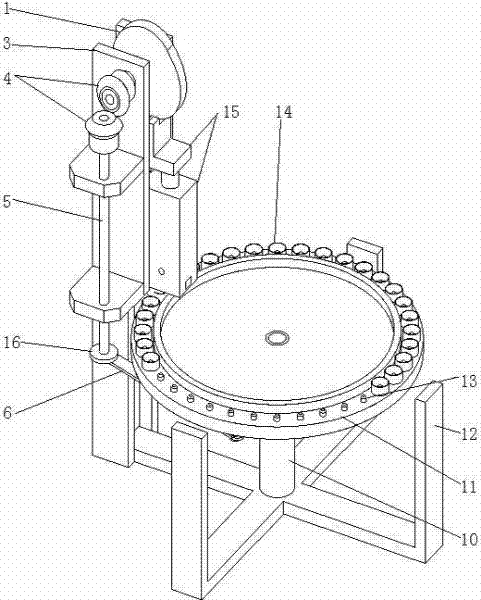

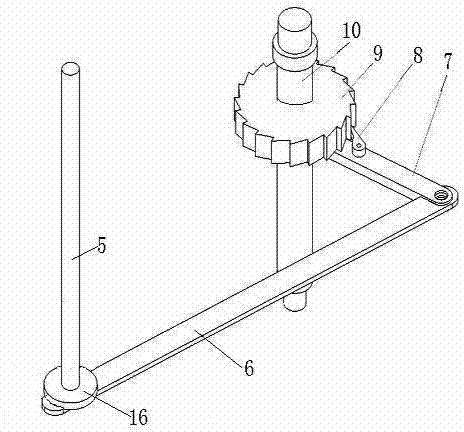

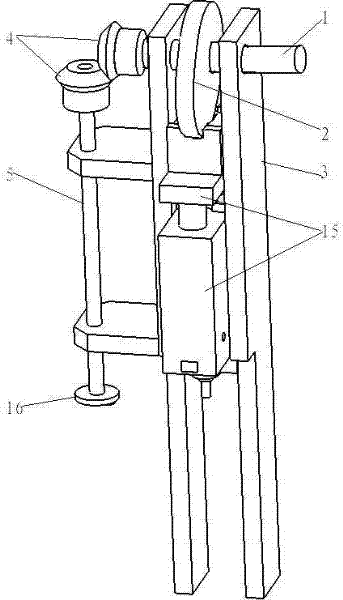

[0014] like Figure 1-3 Shown, the present invention mainly is made up of main turntable part, ratchet mechanism, connecting rod mechanism, cone wheel mechanism, cam mechanism and supporting part. The uppermost part is a cam mechanism and a cone mechanism, the cone mechanism is connected with the upper end of the link mechanism, and the lower end of the link mechanism is connected with the ratchet mechanism, and the ratchet mechanism drives the main turntable part to rotate. The bottom part of the present invention is a supporting part, on which the main turntable components are installed. The cam mechanism is composed of a cam 1 and a camshaft 2, the main turntable part is composed of a main turntable 11 and a positioning round pin 13 on it, the ratchet mechanism is composed of a ratchet claw 8 and a ratchet 9, and the linkage mechanism is composed of a connecting rod 6 and a rocker 7 Composition, the bevel wheel mechanism is made up of a pair of bevel wheel 4 and bevel whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com