Machining process of loudspeaker basin stand with horizontal ear holes

A loudspeaker pot frame and processing technology, which is applied to sensors, electrical components, etc., can solve problems such as punching difficulties, low dimensional control accuracy, and high defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

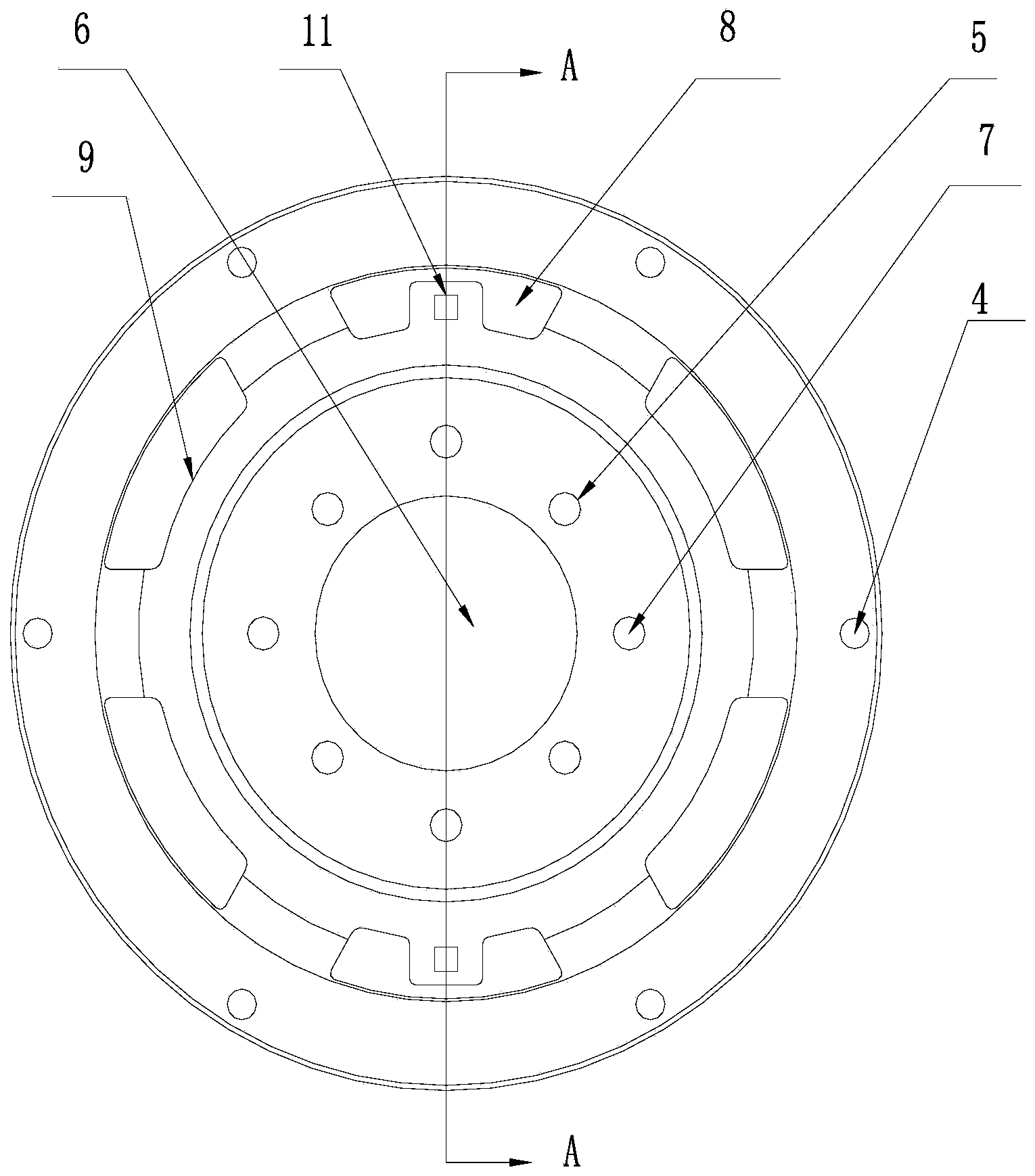

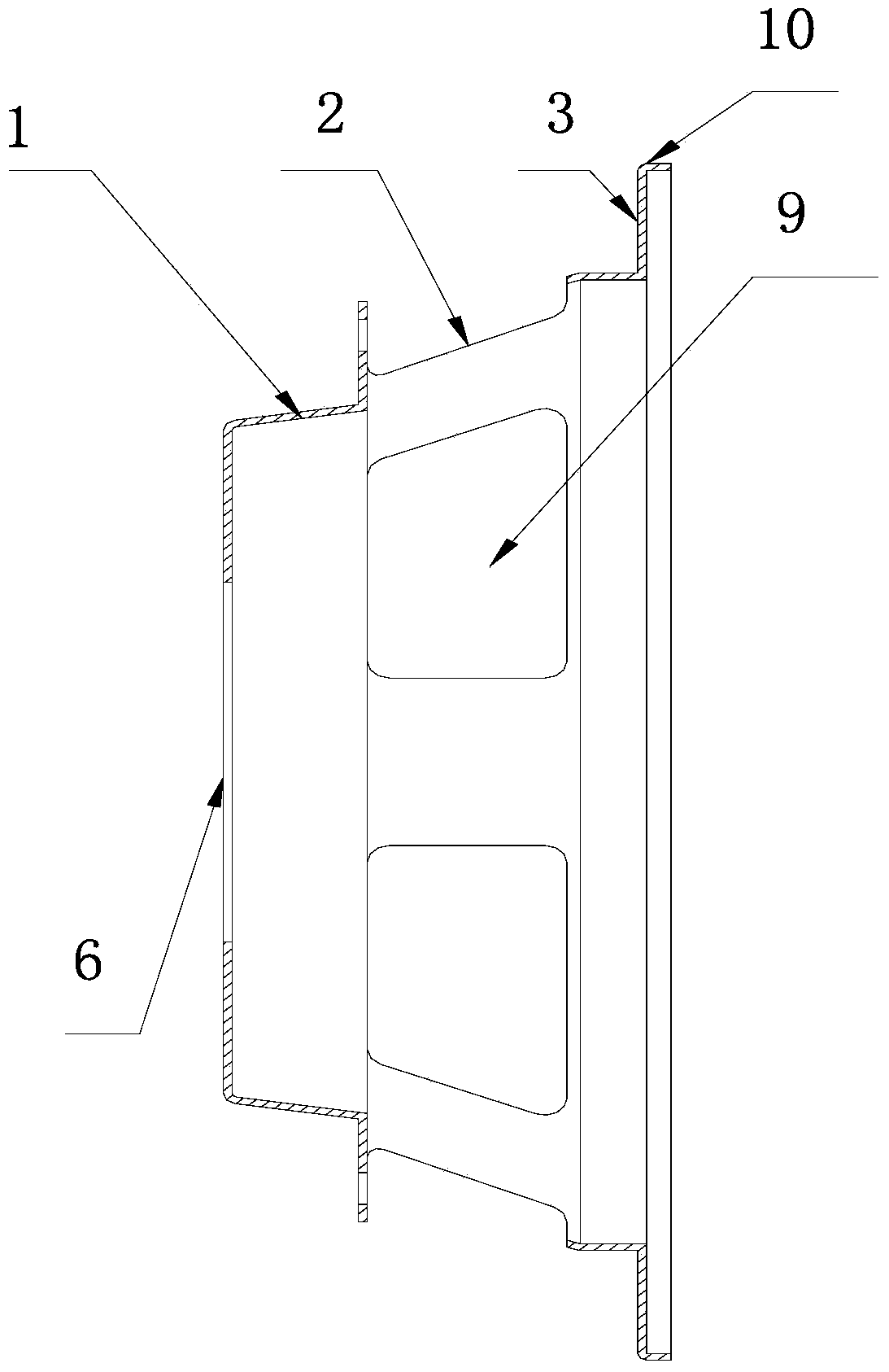

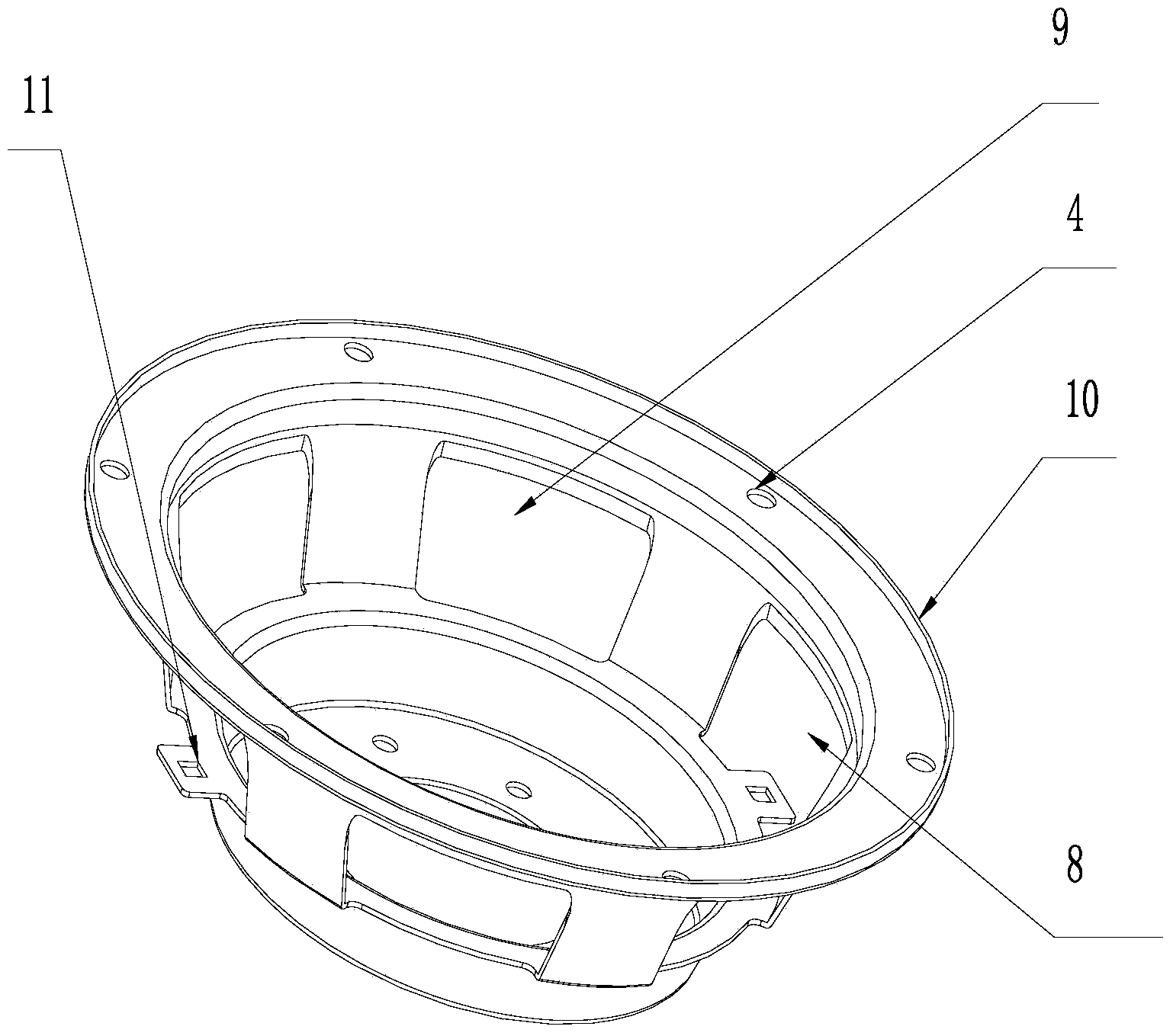

[0024] Such as Figure 1 to Figure 3 Shown, a kind of processing technology of the loudspeaker basin frame with horizontal ear hole, comprises the following steps:

[0025] Step 1: cutting, be 0.8 millimeter in thickness by shearing machine, cut out a square raw material that side length is 182 millimeters on the roll material that width is 182 millimeters;

[0026] Step 2: Blanking, punching out a circular blank with a diameter of 180 mm on the square raw material through the blanking die; the diameter of the punching pin of the blanking die is 180 mm;

[0027] Step 3: Punch the positioning hole, and punch a positioning hole with a diameter of 20 mm in the center of the circular blank through the punching positioning hole die;

[0028] Step 4: stretching, punching out a bowl-shaped semi-finished product on the circular blank with positioning holes punched through the stretching die, the inner diameter of the bowl-shaped semi-finished product increases sequentially from botto...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com