Multilayer printable sheet with a soft or silky touch and manufacturing method thereof

A sheet and paint layer technology, applied in chemical instruments and methods, cellulose plastic material layered products, coatings, etc., can solve the problems of unpleasant touch of acetate film, dull appearance, limited number of colors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

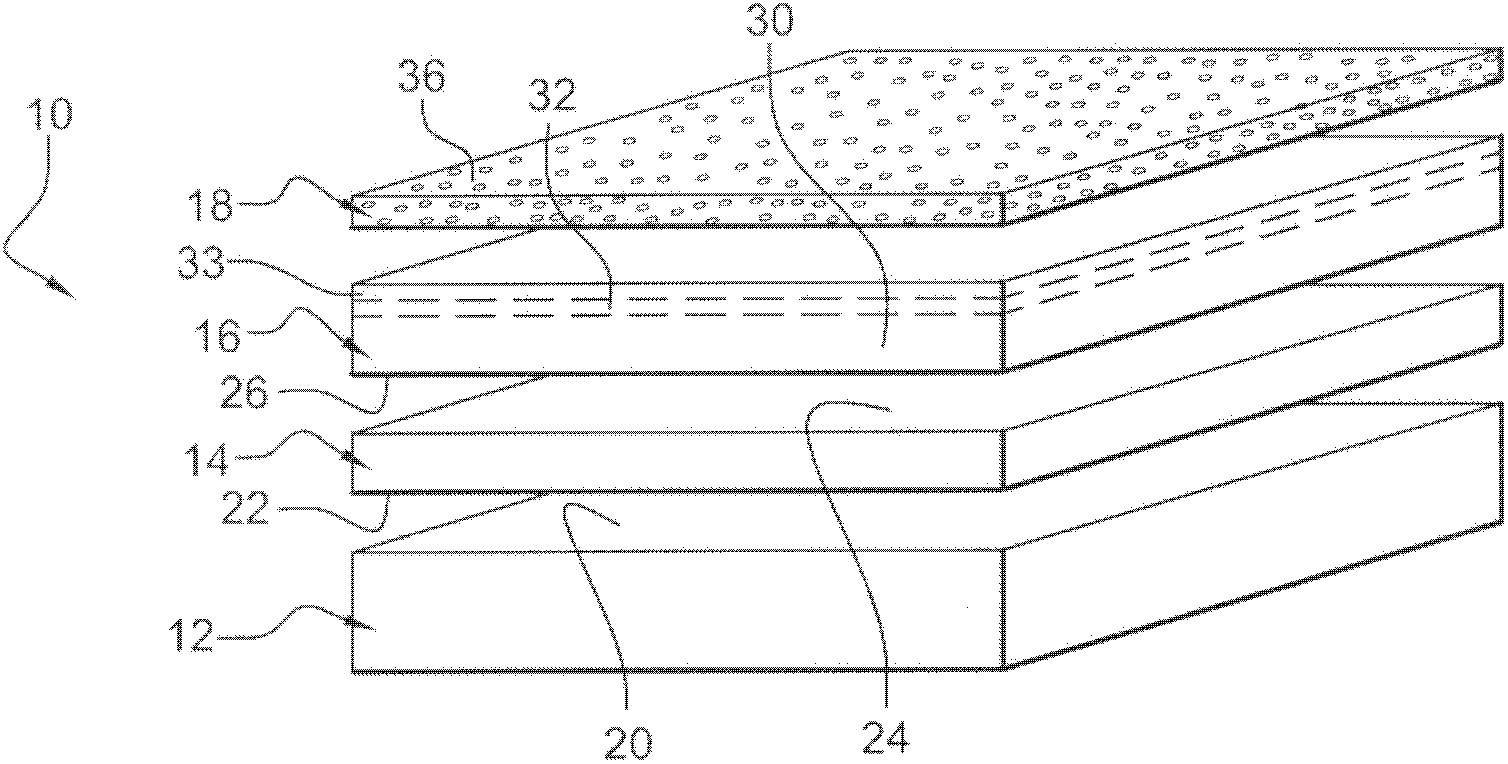

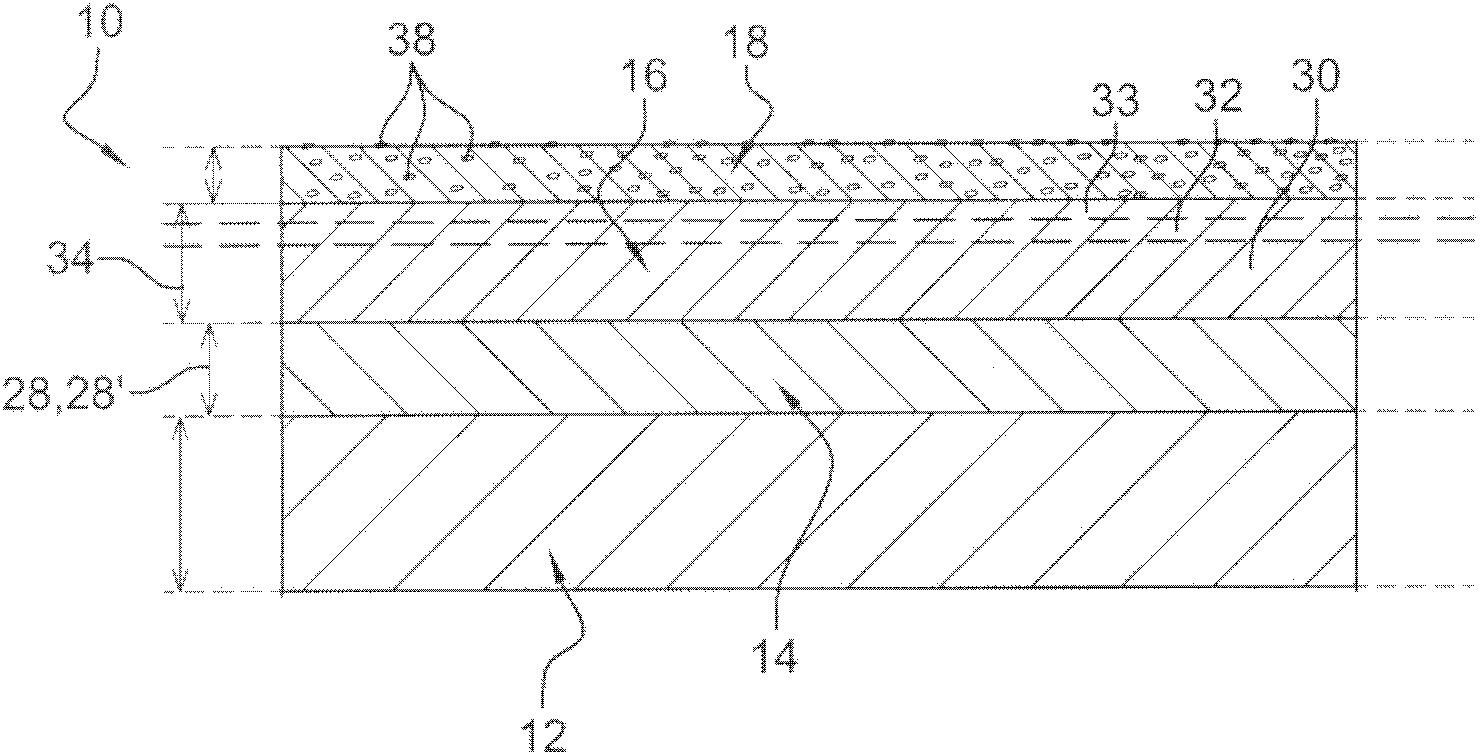

[0107] Example 1: Manufacture of red multilayer sheet

[0108] Use 250g / m2 Main paper sold by Ayo Wiggins Premium Paper Co. Paper as the lower support layer, an aluminum deposition with a thickness of 20 nm as a metal layer, a red varnish with a thickness of 3 μm, a PET film with a thickness of 12 μm as a plastic layer, and a matt varnish layer with the following composition were produced Figure 7 A printable multilayer sheet of the type shown in (without primer sublayer 733). The matt varnish layer has the following composition:

[0109] - By weight, polyurethane particles account for 33%, and its average diameter is about 4μm (trade name sold by Dainishiseika Corporation),

[0110] - By weight, precipitated silica particles (used as a smoothing agent) account for 0.3%, and their average diameter is about 5 μm (trade name Sold by Grace Division),

[0111] - By weight, based on the trade name Rolflex sold by Lamberti The mixture of polyurethane and acrylic adhesive ...

example 2

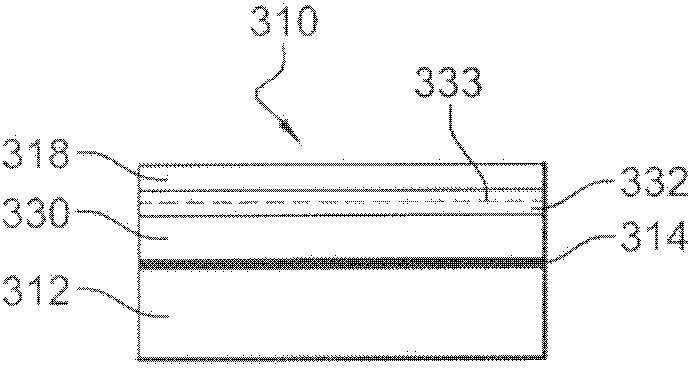

[0114] Example 2: Manufacture of a multilayer sheet of the type of Example 1 with an additional primer sublayer

[0115] Using the same product used in Example 1, except the product used for the support layer is different, prepare Figure 7 Another multi-layer printable sheet of the type (with primer sublayer 733). In this example, the support layer uses 300g / m2 Main The primer sublayer is provided by Luminescence INC., No. 10843X or 11035G. It was provided in an amount of about 1 g / m2 on the upper surface of the PET film, which had been preliminarily treated with acrylic in this example.

example 3

[0116] Example 3: Manufacture of a multilayer sheet of the type of Example 1 additionally with a crosslinker in the matt varnish wear layer

[0117] The matt varnish wear layer included, in addition to the products listed in Example 1, an aziridine-based crosslinker sold under the trade name CX1000 by the company DSM Neoresin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com