Steel printing machine

A technology of stencil printing machine and stamping die, applied in the field of stencil printing machine, can solve the problems of different printing depth, unclear handwriting, laborious and other problems, and achieve the effect of good effect and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

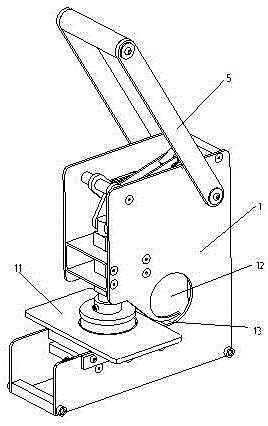

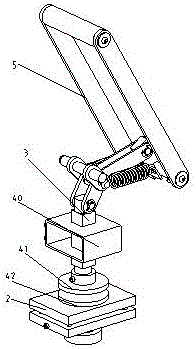

[0027] Such as Figure 1~4 As shown, a stamping machine, it includes:

[0028] base 1;

[0029] Supporting platform 2, described supporting platform 2 is installed on the base 1;

[0030] An action shaft 3, the action shaft 3 is slidingly fitted on the base 1, and the action shaft 3 can move up and down on the base 1;

[0031] die, the die includes an upper die 41 and a lower die 42, the upper die 41 is connected to the lower end of the action shaft 3, and the lower die 42 is installed on the support table 2;

[0032] A driving mechanism, the driving mechanism is movably connected with the action shaft 3, so that when the driving mechanism operates, the action shaft 3 moves up and down on the base 1, thereby driving the upper die 41 away from or toward the lower die 42 to realize embossing on the paper between the upper stamp 41 and the lower stamp 42.

[0033] Wherein, the guiding of the action shaft 3 is realized by the following structure: the action shaft 3 is a square...

Embodiment 2

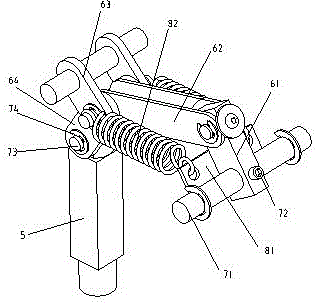

[0044] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is: the specific structure of the driving mechanism. 92, reciprocating rod 93, pivot rod 94 and transition link 95, the power source drives the eccentric wheel 91 to rotate, the bearing 92 is rotatably supported on the eccentric wheel 91, the reciprocating rod 93 One end is hinged with the bearing 92, the other end of the reciprocating rod 93, one end of the pivot rod 94 and one end of the transition link 95 are hinged together, the other end of the pivot rod 94 is pivotally connected to the base 1, The other end of the transition link 95 is hinged to the action shaft 3 .

[0045] The working principle of this embodiment is as follows:

[0046] When the motor 10 rotates, the gear box 20 shifts and outputs an appropriate speed to drive the eccentric wheel 91, and the bearing 92 cooperates with the eccentric wheel 91 to push the reciprocating rod 93 to move back and forth, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com