Method for manufacturing rotary drum pressing die based on dynamic nano engraving technology

A roller and stamper technology, which is applied in the field of making roller stampers based on dynamic nano-scribing technology, can solve the problem of high cost, achieve the effects of low cost, lower cost and solve difficult preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

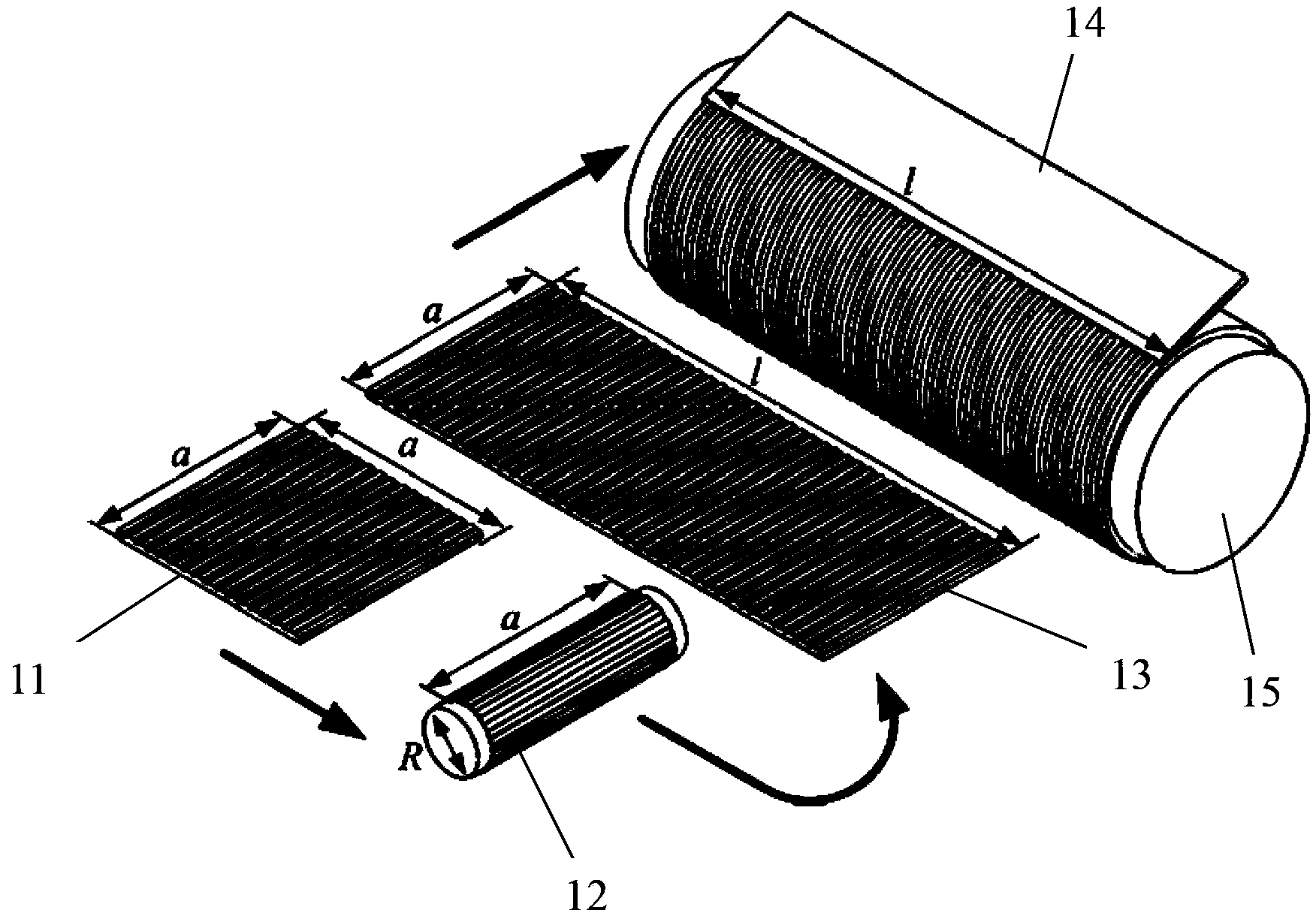

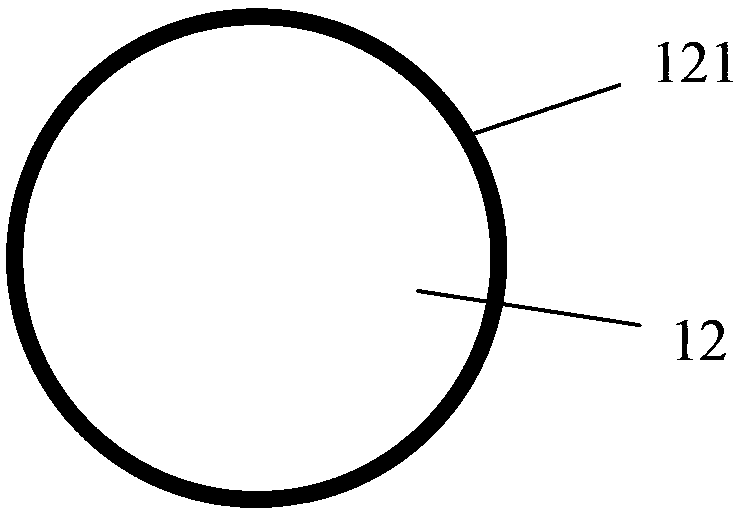

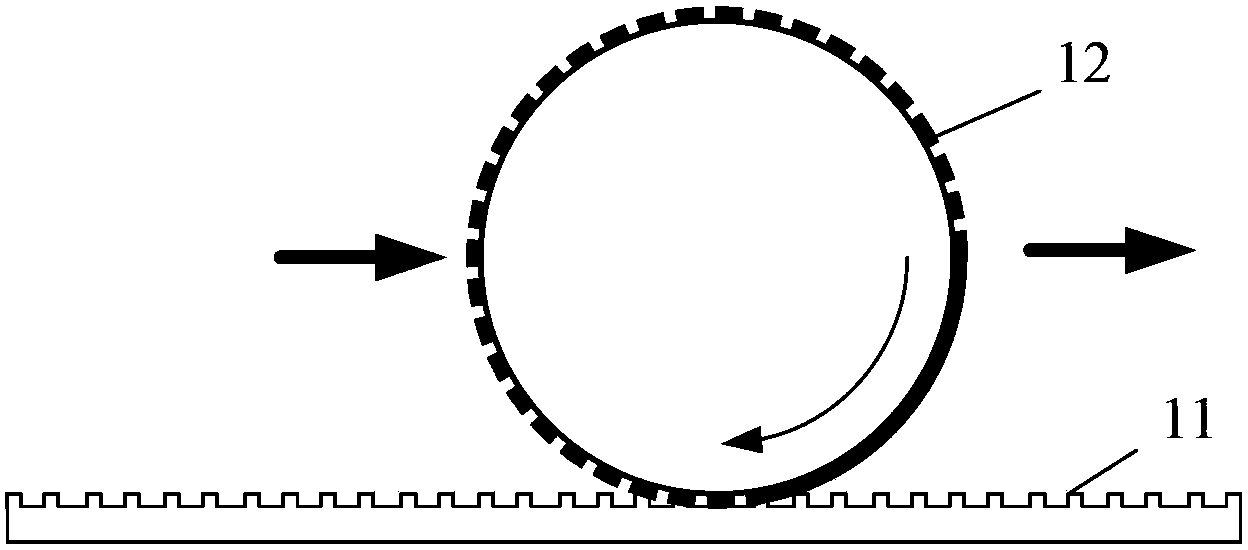

[0033] The embodiment of the present invention discloses a method for making a roller stamper based on dynamic nano-scribing technology. The planar stamper with a nanostructure is brought into contact with the surface of the roller to be processed, and the edge of the fractured surface of the planar stamper is used to draw the surface of the roller to be processed. Nanoscale wire grids are carved on the surface.

[0034] The embodiment of the present invention also discloses a method for making a flat die, comprising the following steps:

[0035] 1. Embossing the first roller through the first flat plate with the nanostructure, forming a structure complementary to the nanostructure on the surface of the first flat plate on the surface of the first roller;

[0036] 1. Embossing the second flat plate by the first roller, forming a structure complementary to the nanostructure on the surface of the first roller on the surface of the second flat plate, and obtaining a planar st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com