Embossing molds for deforming smooth or embossed films

A mold, smoothing technology, applied in the field of imprinting molds, can solve problems such as imprinting and stamping device wear, and achieve the effect of small stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

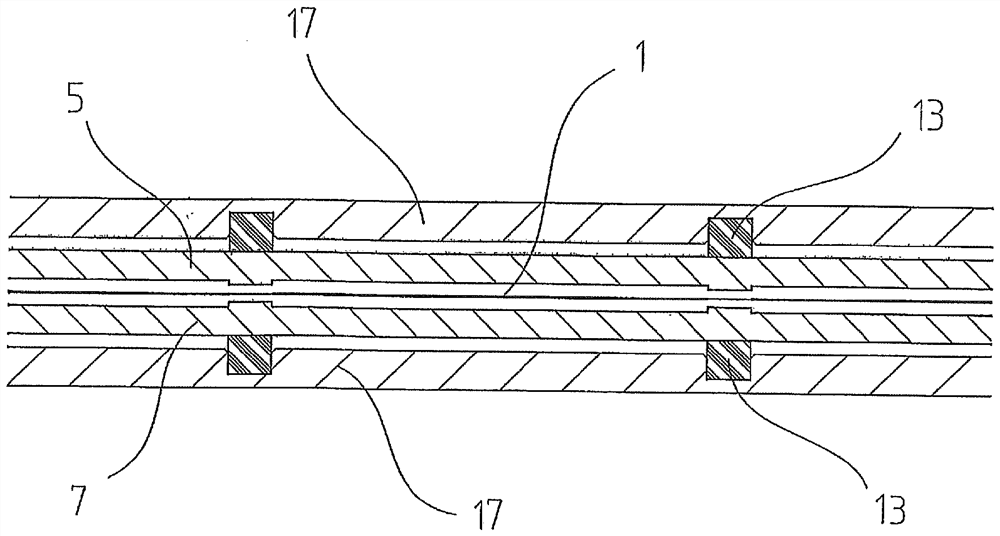

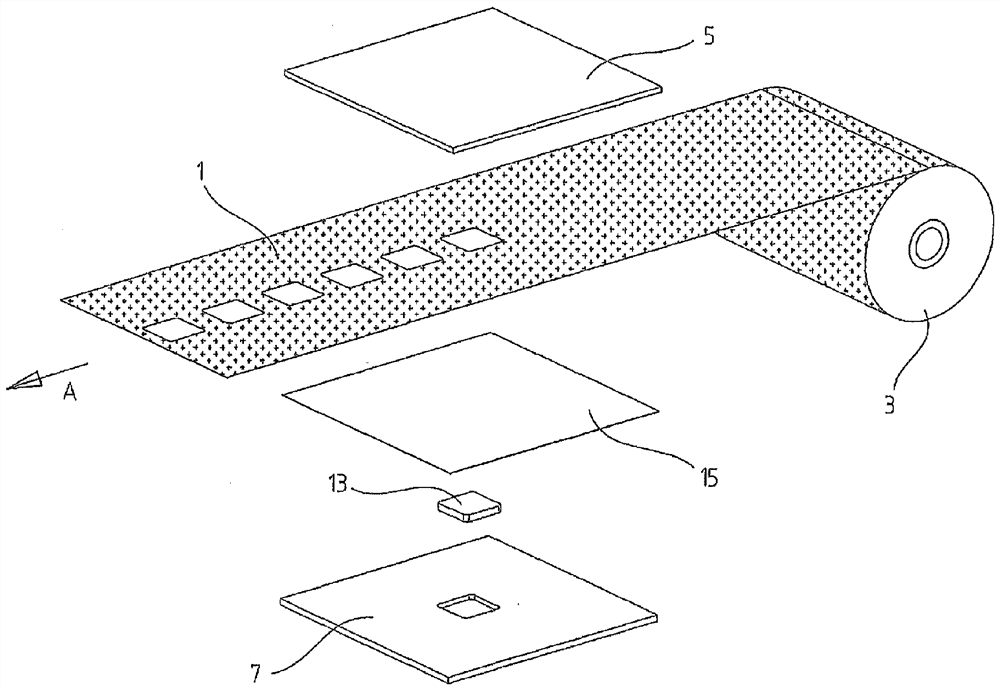

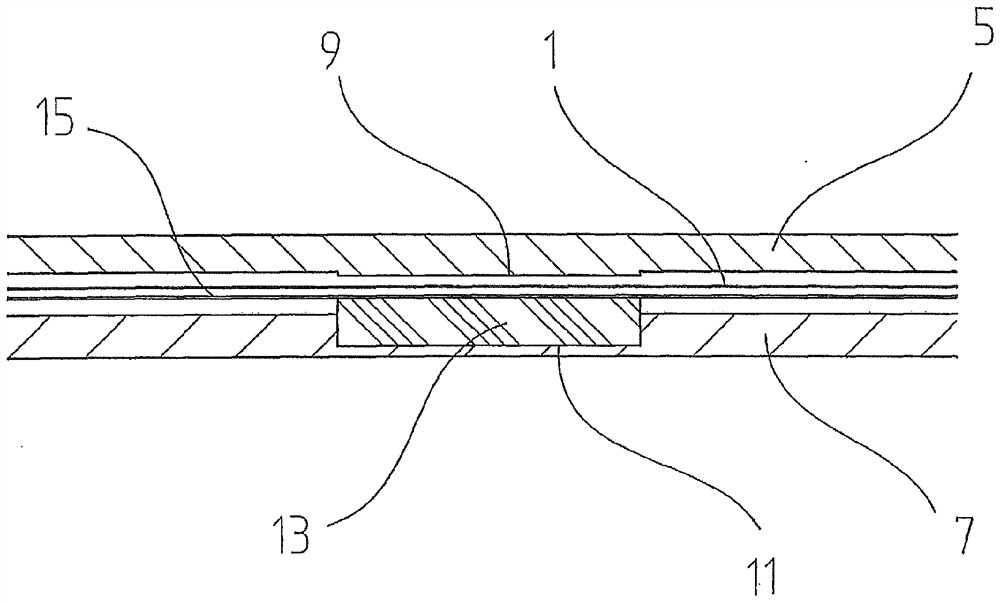

[0020] exist figure 1 In the schematic diagram in , the mold, that is to say the device for removing or eliminating the embossing of selected areas on the embossed film 1 , is shown in an exploded view. Above the film 1 which can be passed from the reel 3 between the die or die plate 5 and the die or receiving plate 7, a projection is formed on the underside of the die 5, here with a smooth surface The raised 9. The cross-section of this protrusion 9 corresponds to the surface on the already embossed film that should eliminate embossing, that is to say, the surface of the film 1 should be deformed completely smoothly again ( figure 2 ). A compensating element 13 is inserted in the groove 11 in the plunger 7 . The compensating element 13 protrudes a few tenths of a millimeter from the surface of the male mold 7 . The cross section of the compensating element 13 substantially corresponds at least to the cross section of the projection 9 in the die 5 .

[0021] The compensa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com