Adaptive connection

A technology for adapting connections and sections, applied to rolling contact bearings, hoisting devices, couplings, etc., can solve problems such as expensive manufacturing, complexity, and unfavorable interface design firmness, and achieve the elimination of gaps and low manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

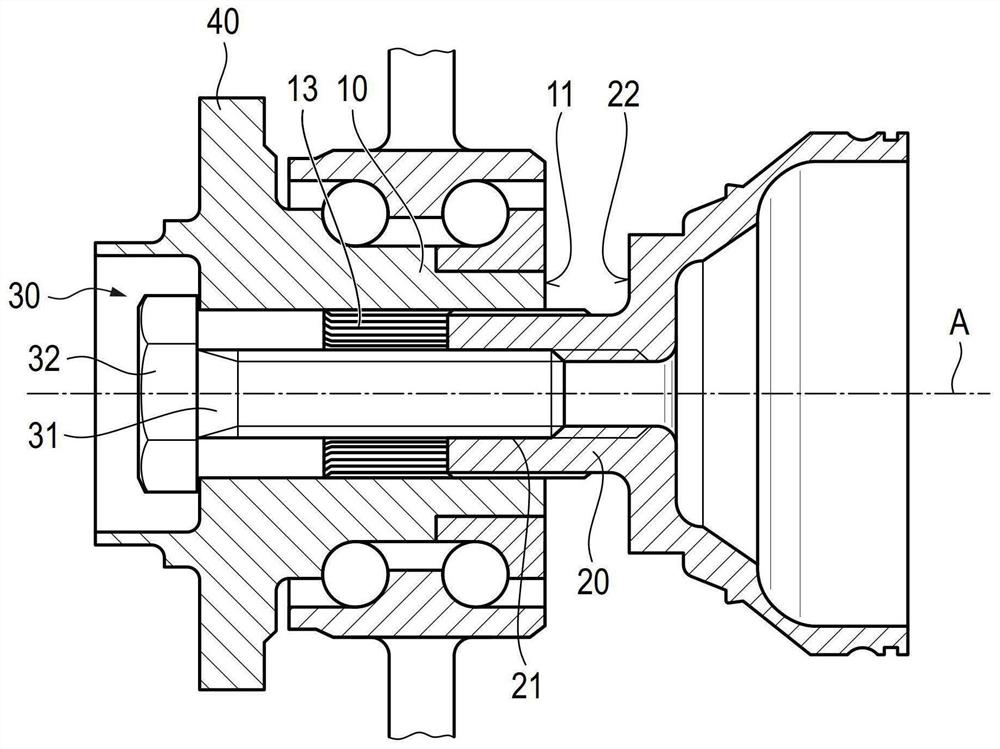

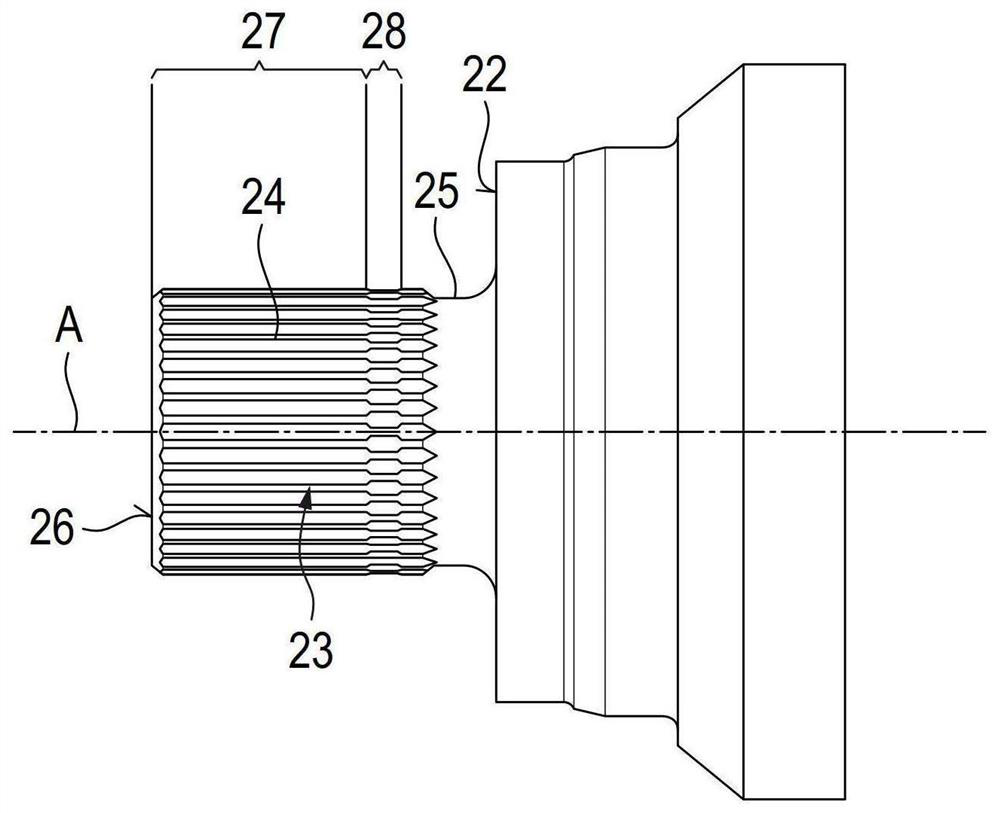

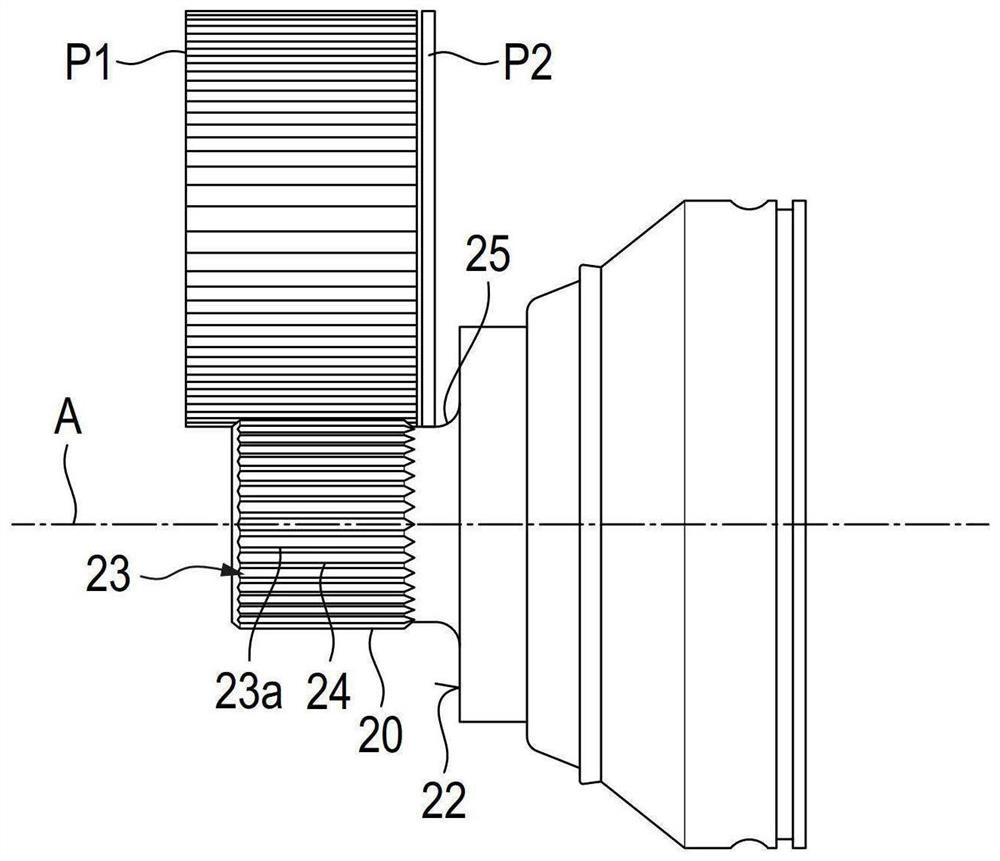

[0043] figure 1 An installation situation of the adapter connection according to the invention is shown as an example. The wheel bearing 1 of the wheel with the hub 10 and the joint outer part 2 of the constant velocity joint of the half shaft with the journal 20 can be seen.

[0044] The journal 20 is inserted axially into the hub 10 and is clamped axially relative to the hub 10 by means of a clamping device 30 . In the present example, fastening bolt 31 is represented as clamping device 30 , which is supported with head 32 on wheel flange 40 and via the wheel flange on hub 10 of the wheel bearing. The fastening screw 30 is screwed at the end into a corresponding threaded opening 21 of the journal 20 .

[0045] In a modification of this exemplary embodiment, a threaded section can be provided on the journal 20 at the end, onto which a fastening nut is screwed as clamping device 30 , the fastening nut itself being supported on the hub 10 .

[0046] figure 1 shows the wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com