Integrated water tank type crystallizer used for casting 7 series extra super duralumin alloy

A technology of hard aluminum alloy and crystallizer, which is applied in the field of integral water tank type crystallizer, can solve the problems of ingot casting ingot cracks and uneven distribution of water cooling, and achieve the effect of reducing crack tendency, uniform stress distribution and meeting the use requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

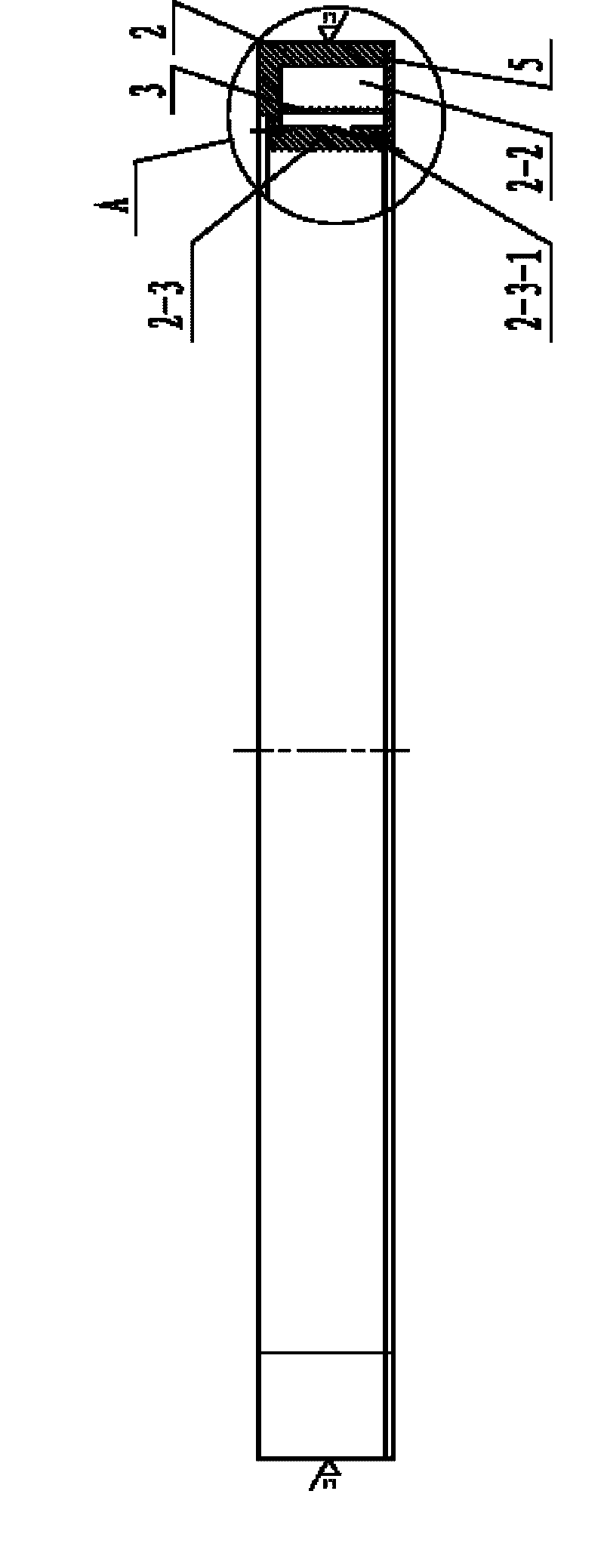

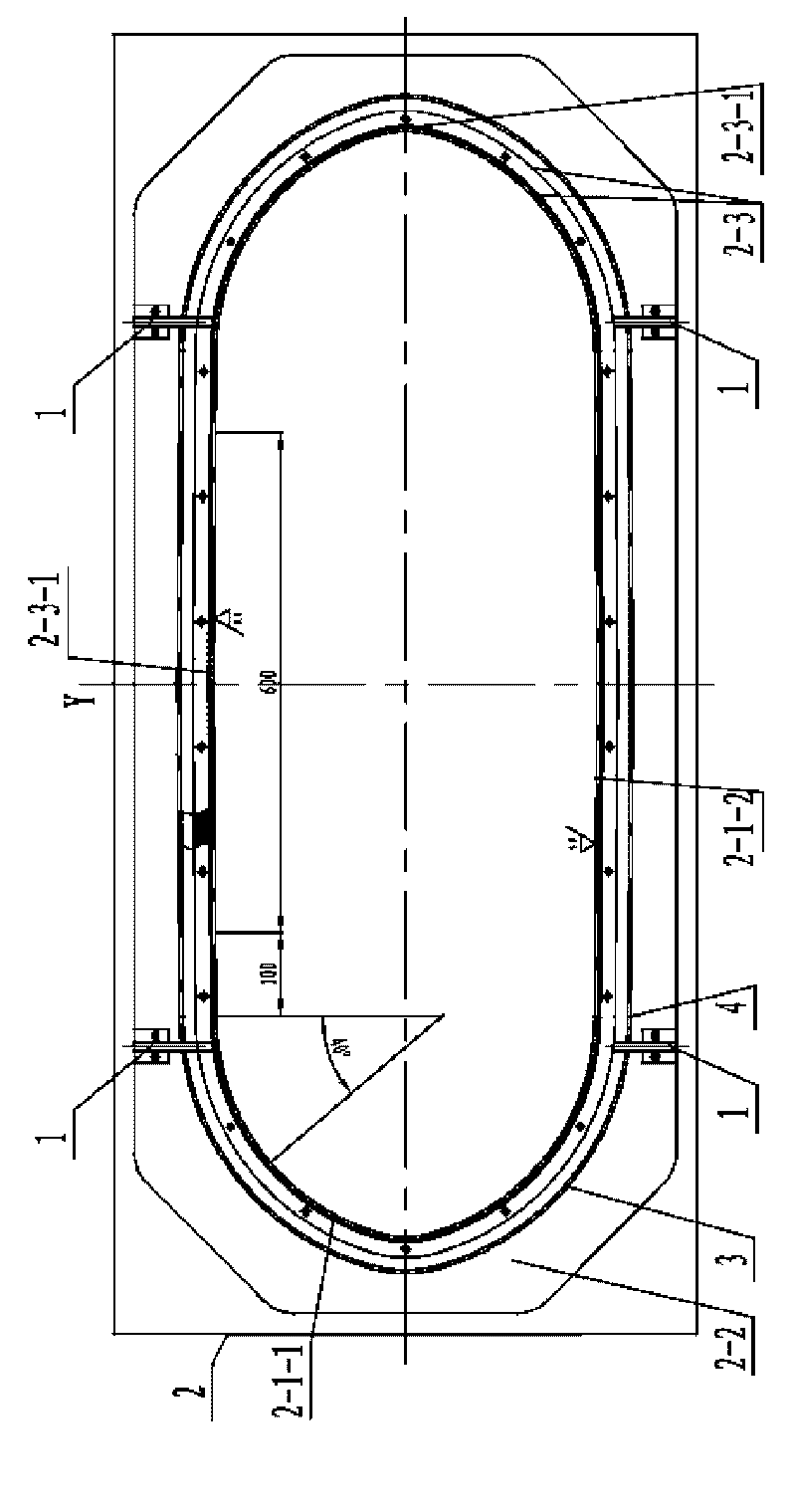

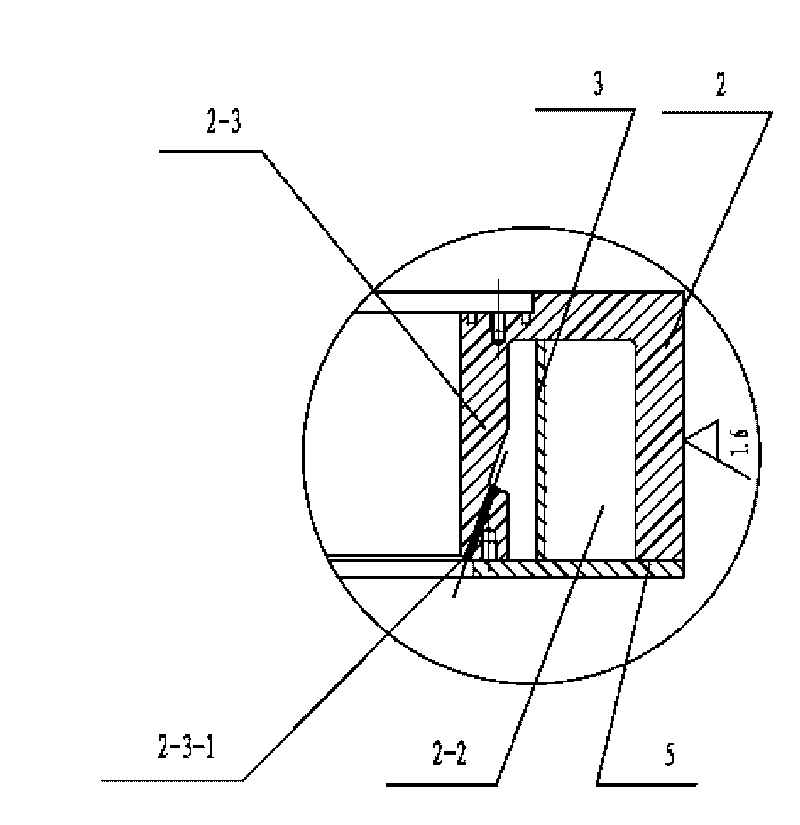

[0015] Specific implementation mode one: as figure 1 and 2 As shown, the integral water tank mold for casting 7-series superhard aluminum alloys described in this embodiment includes a crystallizer box 2 and a mold lower cover 5, and the mold lower cover 5 is airtightly arranged on the mold box 2, on the large surface of the crystallizer box 2, there is a flat through hole 2-1 (the inner wall of the crystallizer box 2 is the inner working surface of the crystallizer), and the crystallizer also includes four The partition 1, the cross-sectional profile shape of the flat through hole 2-1 is composed of two arc segments 2-1-1 and two straight segments 2-1-2, the two straight segments 2-1-2 The two ends are respectively connected by circular arc segments 2-1-1; each circular arc segment 2-1-1 is formed by butting two circular arcs with different diameters; There is an annular groove 2-2, and several water outlet holes 2-3-1 are evenly distributed on the lower end surface of the ...

specific Embodiment approach 2

[0017] Specific implementation mode two: as figure 1 and 2 As shown, the crystallizer in this embodiment also includes two small surface water distribution plates 3 and two large surface water distribution plates 4, and the two small surface water distribution plates 3 are respectively arranged in the annular groove 2-2 Between the two partitions 1 at the end, the two large surface water distribution plates 4 are respectively arranged between the two partitions 1 in the middle of the annular groove 2-2. Two small surface water distribution boards 3 and two large surface water distribution boards 4 can realize secondary water distribution to make the water outlet more uniform. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0018] Specific implementation mode three: as figure 1 and 2 As shown, in this embodiment, the diameter of the water outlet hole 2-3-1 in the area of 600mm centered on the vertical line Y is 4.5, The diameter of the water outlet hole 2-3-1 in the 100mm area on both sides is 4mm, and the water outlet hole in the area where the central angle of the transition between the arc segment 2-1-1 and the straight line segment 2-1-2 is 40° The diameter of 2-3-1 is 3.5 mm, and the diameter of the outlet hole 2-3-1 at the rest of the lower end surface of the annular water distribution hole wall body 2-3 is 3 mm. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

[0019] Segmented control of the crystallizer water hole, the diameter of the water hole is Φ3~4.5mm, the size is different, the large and small surface of the crystallizer is designed with a water baffle, which can realize the independent control of the water strength of the large and sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com