Online automatic cleaning equipment for hanging tool of spraying production line and cleaning method thereof

An automatic cleaning and production line technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of time-consuming, labor-intensive, high labor intensity, and reduced electrical conductivity of hanging tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail without limitation in conjunction with the accompanying drawings and embodiments below.

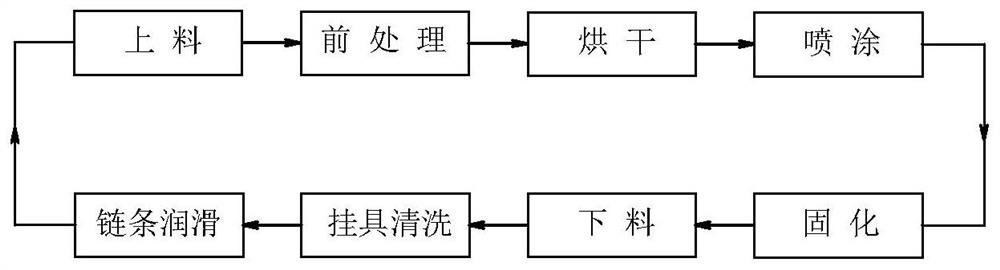

[0040] Such as figure 1 As shown, the hanger online automatic cleaning equipment of the present invention is set in the existing spraying production line to form a new spraying production line. The flow process of the new spraying production line is as follows: workpiece loading→pretreatment→drying→spraying→curing→workpiece unloading→ Automatic cleaning of hangers → automatic chain lubrication → workpiece loading.

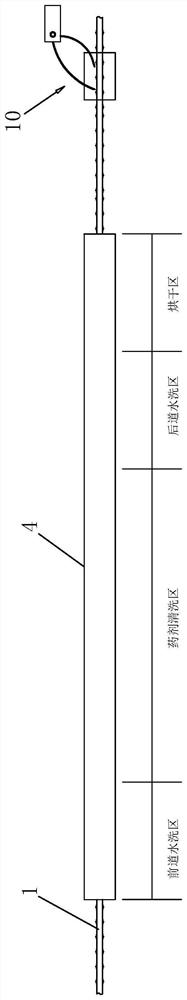

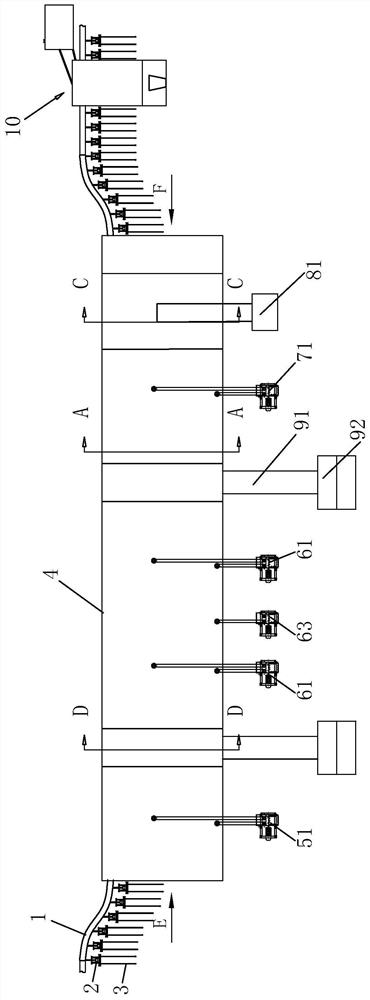

[0041] Such as figure 2 , image 3 and Figure 6 As shown, the spraying production line is provided with a closed-loop chain guide rail 1 and a closed-loop conveying chain 2 arranged on the chain guide rail 1, and several hangers 3 are suspended on the conveying chain 2.

[0042] Among them, the hanger online automatic cleaning equipment includes: an airtight box body 4, the chain guide rail 1 and the convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com