Automatic lubrication type guide pole device and mold positioning apparatus including the guide pole device

A technology of automatic lubrication and positioning device, applied in the direction of engine lubrication, engine components, mechanical equipment, etc., can solve problems such as affecting production accuracy, shortening the service life of mold 14, rusting, etc., to avoid dryness and improve production accuracy. and the effect of mold life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

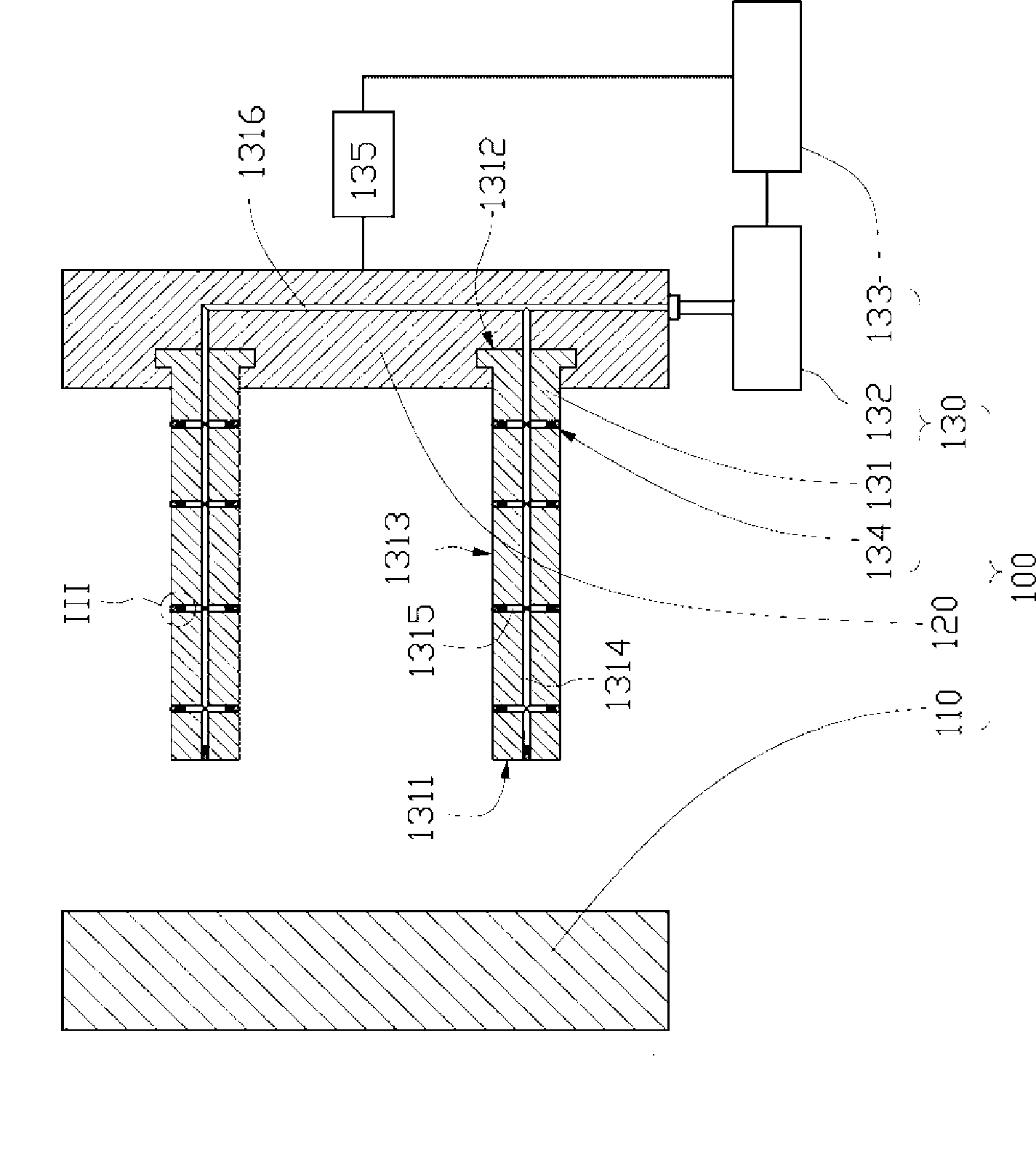

[0014] The automatic lubricating guide post device of the present technical solution and the mold positioning device including the automatic lubricating guide post device will be further described below in conjunction with the accompanying drawings.

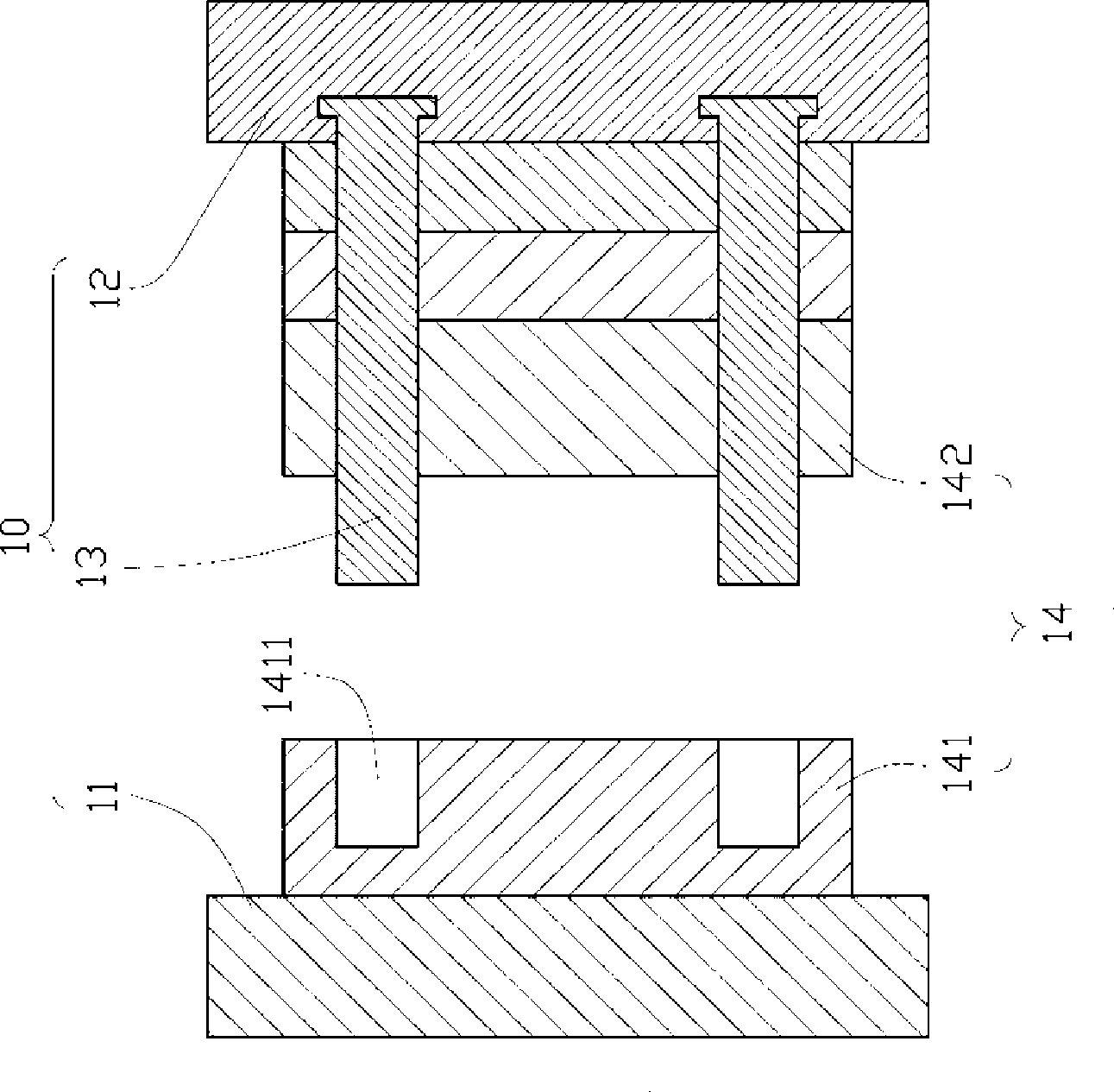

[0015] see figure 2 , The mold positioning device 100 provided by the embodiment of the technical solution includes a first splint 110 , a second splint 120 and an automatic lubricating guide post device 130 .

[0016] The second clamping plate 120 is opposite and parallel to the first clamping plate 110, and it can move towards the first clamping plate 110 under the drive of its drive system, so that the distance between the first clamping plate 110 and the second clamping plate 120 can be shortened according to the size of the mold. And the mold is fixed between the first clamping plate 110 and the second clamping plate 120 .

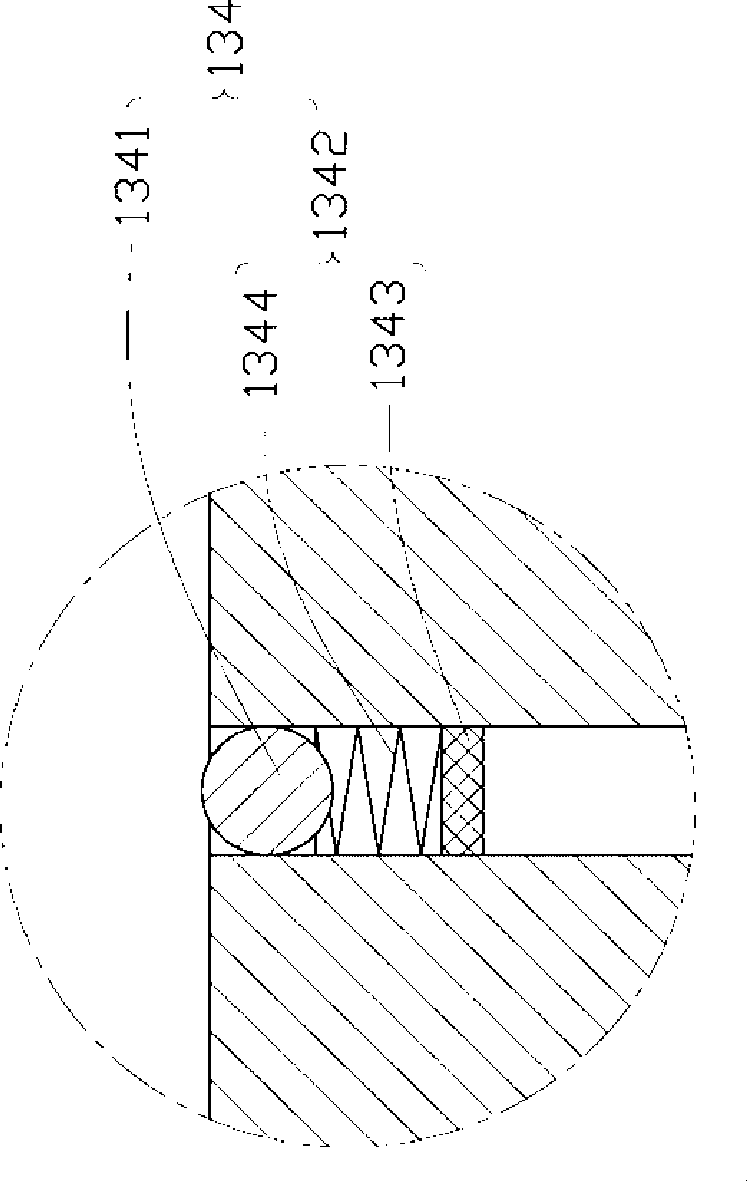

[0017] The automatic lubricating guide post device 130 includes a guide post 131 , an oil supply de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com